Antistatic biodegradable foaming material and preparation method thereof

A biodegradable and foam material technology, applied in the field of antistatic biodegradable foam material and its preparation, can solve problems such as the decline of material mechanical properties, and achieve the effects of improving mechanical properties, good water resistance, and reducing radiation processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

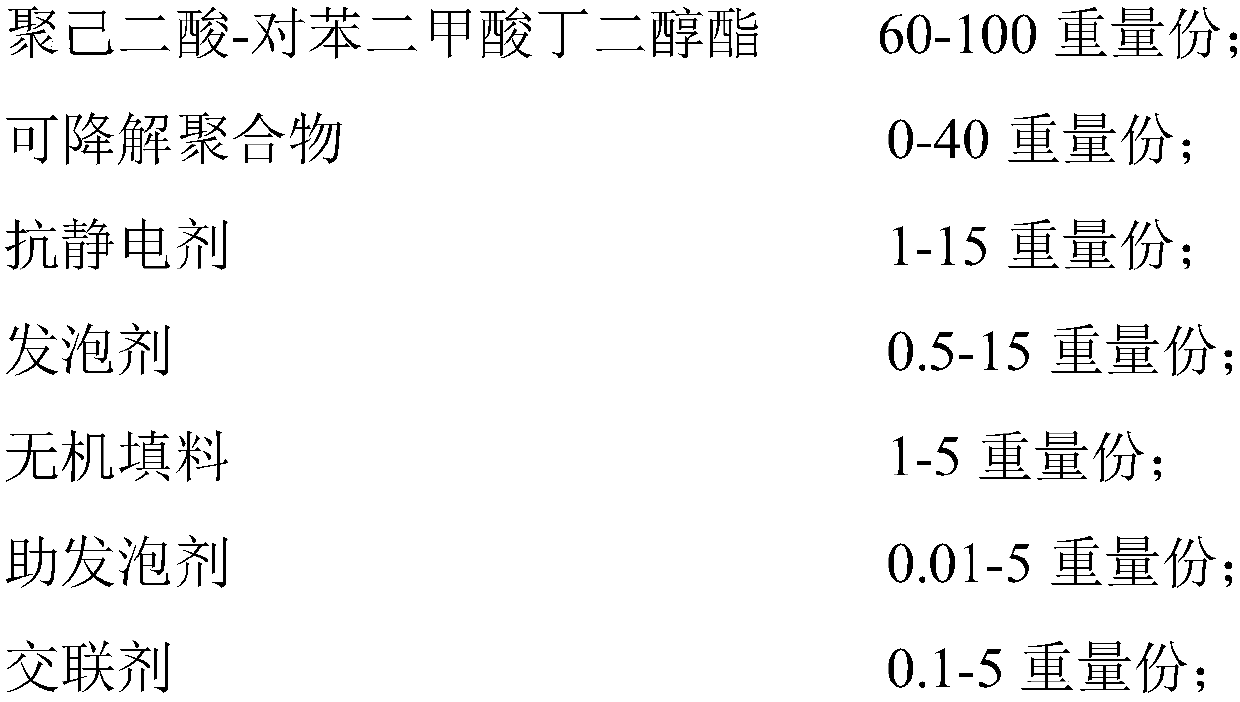

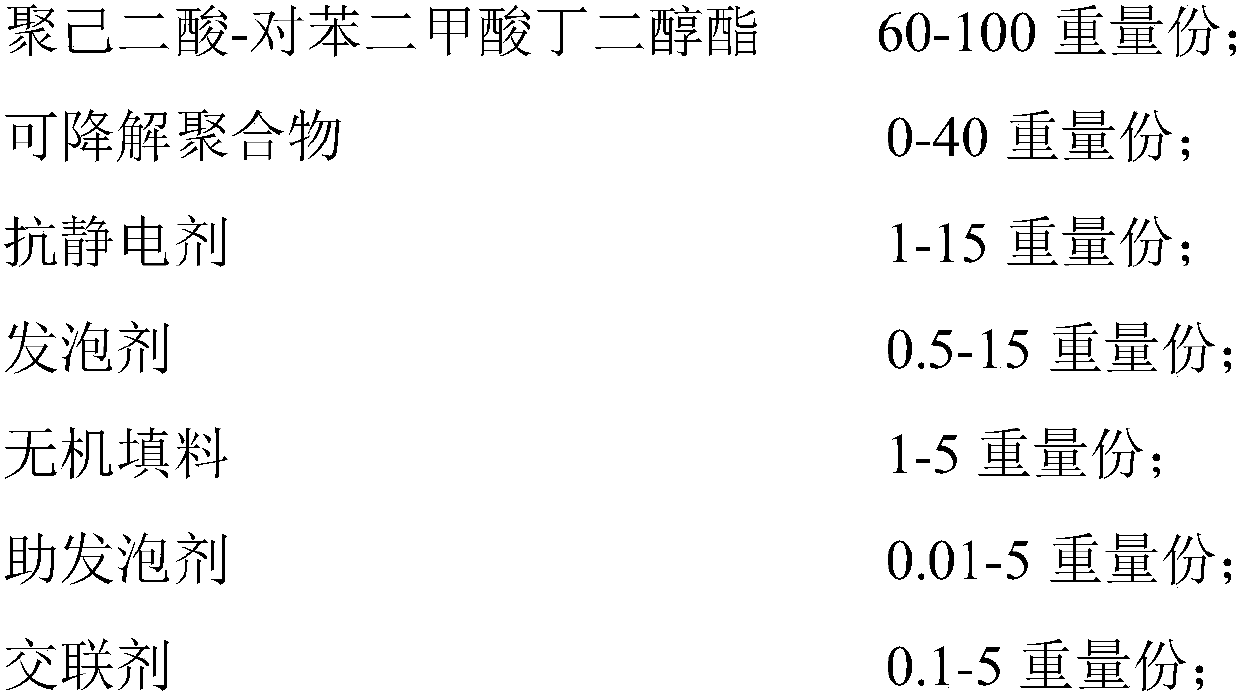

Method used

Image

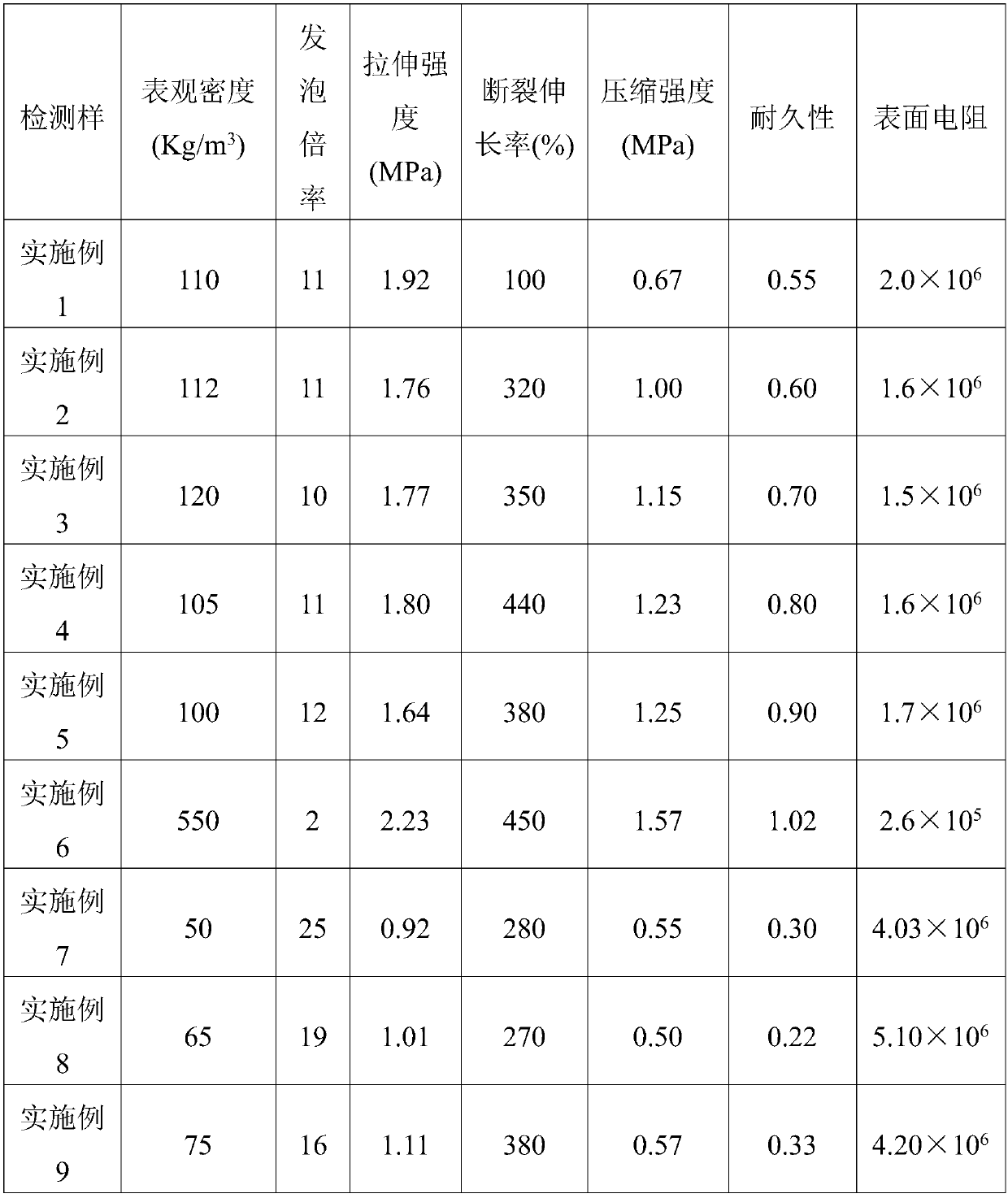

Examples

preparation example Construction

[0030] The preparation method of antistatic biodegradable foam material of the present invention, the steps are as follows:

[0031] Step 1. Weigh each raw material according to the composition and parts by weight, and add it to a twin-screw extruder for mixing and granulation. The mixing and granulation temperature is 80-170°C. Extrude the sheet on the machine, the thickness of the sheet is 0.5-3.0mm, preferably 1mm, and the extrusion temperature is 100-170°C;

[0032] Step 2, in the air at room temperature, use an electron accelerator or cobalt ( 60 Co) source ionizing radiation irradiates the blend sheet with ionizing radiation at a dose of 2-100KGy, preferably 80-90KGy, to obtain a crosslinked material;

[0033] Alternatively, in the air at room temperature, ionizing radiation is performed on the sheet obtained in step 1, and the irradiation dose is 0.5-9KGy to obtain a pre-crosslinked material; the pre-crosslinked material is further processed in a hot water bath at 50-8...

Embodiment 1

[0037]The antistatic biodegradable foam material consists of 100 parts by weight of polybutylene adipate-terephthalate, 15 parts by weight of conductive carbon black, 5 parts by weight of azodicarbonamide, 5 parts by weight of calcium carbonate, and zinc oxide 1 part by weight and 0.5 part by weight of triallyl isocyanurate.

[0038] The preparation method of the above-mentioned antistatic biodegradable foam material: first weigh the above-mentioned raw materials according to the composition and parts by weight, then use a twin-screw extruder to carry out mixing and granulation, the mixing and granulation temperature is 80-170°C, and then use a single The screw extruder is extruded into a sheet, the extrusion temperature is 100-170°C, and the thickness of the sheet is 1.0mm. Using an electron accelerator, the sheet is irradiated in air at room temperature, and the irradiation dose is 100KGy. Foaming was carried out in a vertical foaming furnace, the foaming temperature was 22...

Embodiment 2

[0041] The antistatic biodegradable foam material consists of 70 parts by weight of polybutylene adipate-terephthalate, 30 parts by weight of polylactic acid, 7 parts by weight of conductive carbon black, 5 parts by weight of azodicarbonamide, and calcium carbonate 5 parts by weight, 1 part by weight of zinc oxide and 0.5 parts by weight of triallyl isocyanurate.

[0042] The preparation method of the above-mentioned antistatic biodegradable foam material: first weigh the above-mentioned raw materials according to the composition and parts by weight, then use a twin-screw extruder to carry out mixing and granulation, the mixing and granulation temperature is 80-170°C, and then use a single The screw extruder is extruded into a sheet, the extrusion temperature is 100-170°C, and the thickness of the sheet is 1.0mm. use 60 Co source, the sheet is irradiated in air at room temperature, and the irradiation dose is 100KGy. Foaming was carried out in a vertical foaming furnace, the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com