Starch acetate-polydioxanone graft copolymer/inorganic particulate nano composite material and preparation method thereof

A technology of polydioxanone and nanocomposite materials, which is applied in the field of polymer and inorganic nanofiller composite materials and their preparation, and can solve the problems of unfavorable processing and molding, limiting the wide application of general-purpose plastics, and low melt strength. Achieve the effect of increasing the biodegradation rate, requiring low reaction conditions, and no pollution to the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

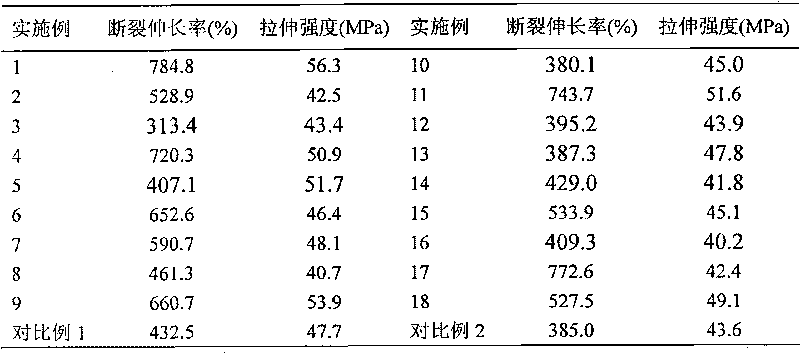

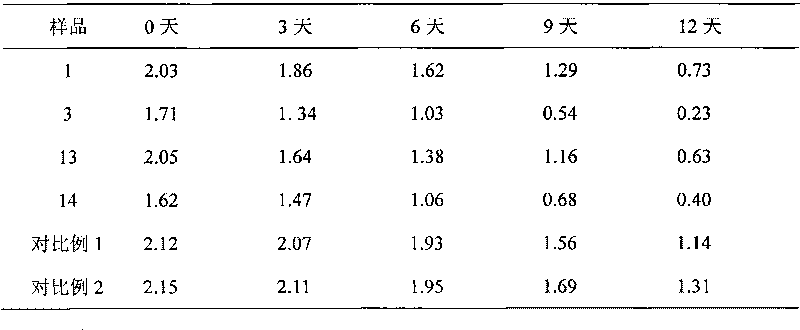

Examples

Embodiment 1

[0021] Add 5 parts of starch acetate with a degree of substitution of 2.3 and a molecular weight of 30,000, 95 parts of freshly distilled p-dioxanone monomer and 5 parts of montmorillonite into the reaction bottle in sequence, and ultrasonically disperse under the protection of nitrogen atmosphere for 2 hour, make the starch acetate completely dissolve in the p-dioxanone monomer, at the same time make the montmorillonite swell, then raise the temperature to 80°C, and then add triethylaluminum with a molar ratio of 0.002 to p-dioxanone The catalyst is reacted for 6 hours to obtain the starch acetate-polydioxanone graft copolymer / inorganic particle nanocomposite material.

Embodiment 2

[0023] Add 15 parts of starch acetate with a degree of substitution of 2.3 and a molecular weight of 50,000, 85 parts of freshly distilled p-dioxanone monomer and 7 parts of montmorillonite into the reaction bottle in sequence, and ultrasonically disperse them under the protection of nitrogen atmosphere for 2 hour, make the starch acetate completely dissolve in the p-dioxanone monomer, at the same time make the montmorillonite swell, then raise the temperature to 120°C, and then add aluminum isopropoxide with a molar ratio of 0.004 to p-dioxanone The catalyst is reacted for 12 hours to obtain the starch acetate-polydioxanone graft copolymer / inorganic particle nanocomposite material.

Embodiment 3

[0025] Add 40 parts of starch acetate with a degree of substitution of 2.9 and a molecular weight of 50,000, 60 parts of freshly distilled p-dioxanone monomer and 0.5 part of montmorillonite into the reaction bottle in sequence, and ultrasonically disperse under the protection of nitrogen atmosphere for 1 hour, make the starch acetate completely dissolve in the p-dioxanone monomer, at the same time make the montmorillonite swell, then raise the temperature to 90°C, and then add triethylaluminum with a molar ratio of 0.004 to p-dioxanone The catalyst is reacted for 12 hours to obtain the starch acetate-polydioxanone graft copolymer / inorganic particle nanocomposite material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of substitution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com