Method for treating benzoic-acid-containing waste water and anaerobic biodegradation method for benzoic acid

An anaerobic biology and treatment method technology, which is applied in the field of anaerobic biodegradation of benzoic acid and the treatment of wastewater containing benzoic acid, can solve the problem of low anaerobic biodegradation rate of benzoic acid, and achieve the effect of increasing the degradation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

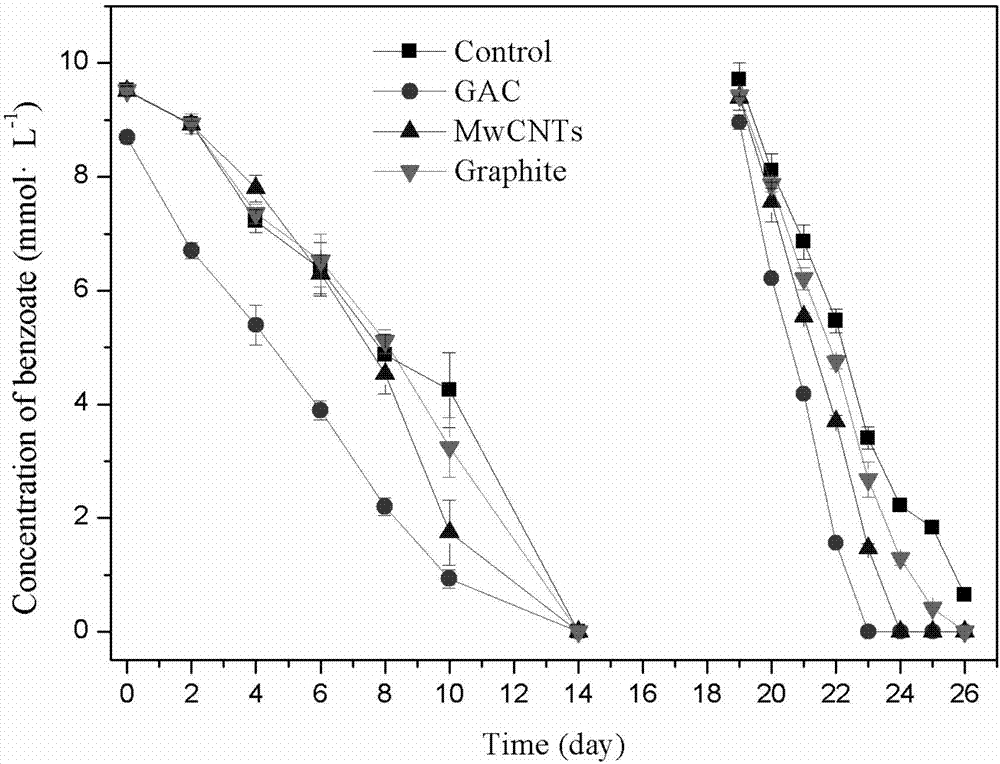

Embodiment 1

[0048] Prepare 500mL of medium concentrate: weigh 5g KH 2 PO 4 ,50gNH 4 Cl, 40gNaCl, 10gMgSO 4 ·7H 2 O,2gCaCl 2 2H 2 O was dissolved in a beaker filled with 500ml of deionized water. After the dissolution was complete, it was transferred to a 500mL blue-necked bottle for later use. Other ingredients are shown in Table 2.

[0049] Configure 1000 times of trace element and vitamin concentrates, as shown in Table 3 and Table 4.

[0050] Prepare 20g / L multi-walled carbon nanotubes: first dissolve 2g of multi-walled carbon nanotubes into a blue-necked bottle filled with 100ml of deionized water, mix well after ultrasonication for 30min, and set aside.

[0051] Configure 1M sodium benzoate stock solution: weigh 14.4g of sodium benzoate and dissolve it in a beaker filled with 100ml of deionized water, then transfer it to a 120ml serum bottle, and use N 2 :CO 2 = After 15 minutes of aeration with the mixed gas of 4:1, package it for later use.

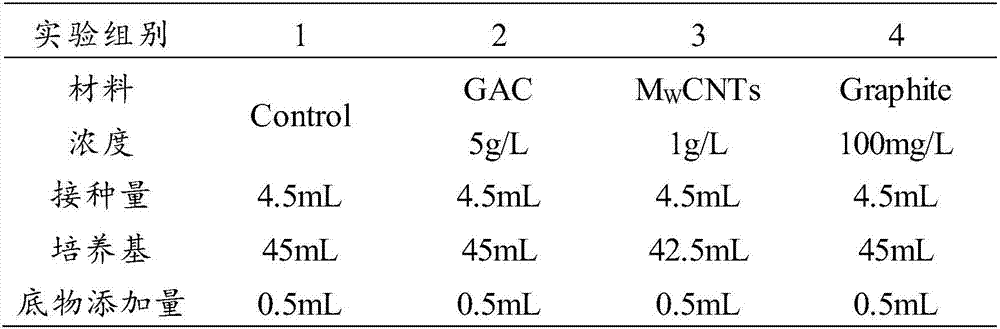

[0052] Take 12 clean serum bot...

Embodiment 2

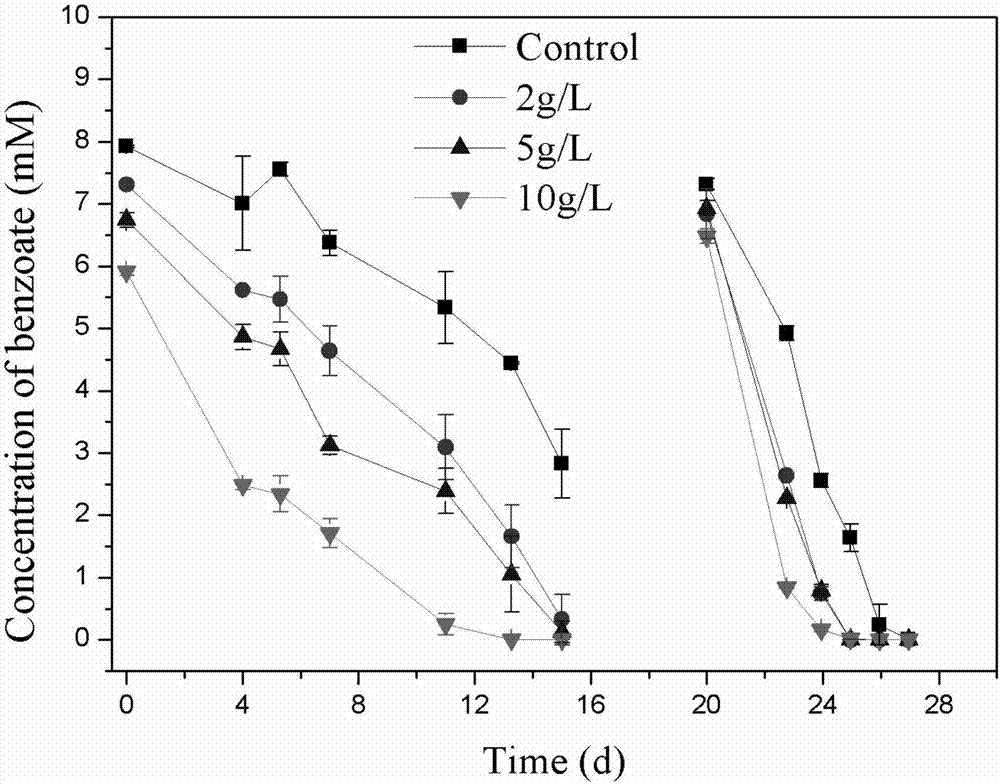

[0073] Taking activated carbon as an example, the effects of different concentrations of activated carbon on the anaerobic degradation rate of benzoic acid were explored.

[0074] Take 12 clean serum bottles with a volume of 120 mL, add different concentrations of activated carbon, transfer them to an anaerobic glove box, and add 45 mL of medium solution respectively.

[0075] Then, take out 100ml of the mother liquor containing benzoic acid-degrading bacteria, after centrifuging at 8000g, remove the supernatant, put into the glove box and dissolve the mud at the bottom with 100ml of new medium, pour it into a 250mL beaker, and Mix evenly under the agitator, then transfer 4.5mL to 12 vials with a 5mL pipette gun, respectively add to 120ml serum bottles (to ensure the same inoculum volume), and package.

[0076] Add 0.5 mL of benzoic acid stock solution to each vial, then wash with N 2 :CO 2 = 4:1 mixed gas replaces the headspace gas, and then cultures at 37°C in a dark and v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com