A wastewater percolation tank and a wastewater percolation system

A percolation tank and sewage technology, applied in water/sludge/sewage treatment, chemical instruments and methods, special treatment targets, etc., can solve the problems of high power consumption and poor sewage treatment effect, reduce consumption and ensure water output Water quality and the effect of sludge reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

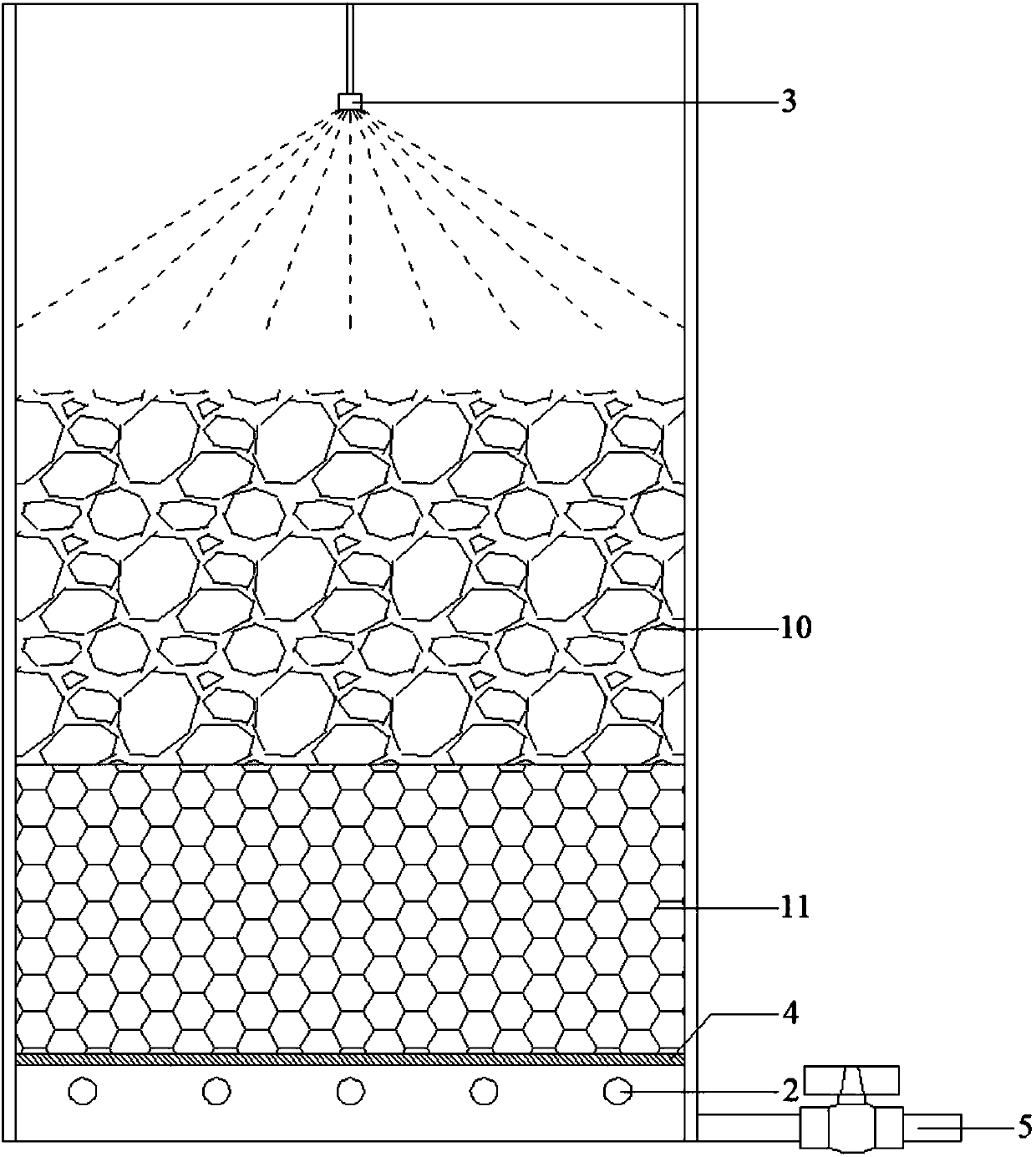

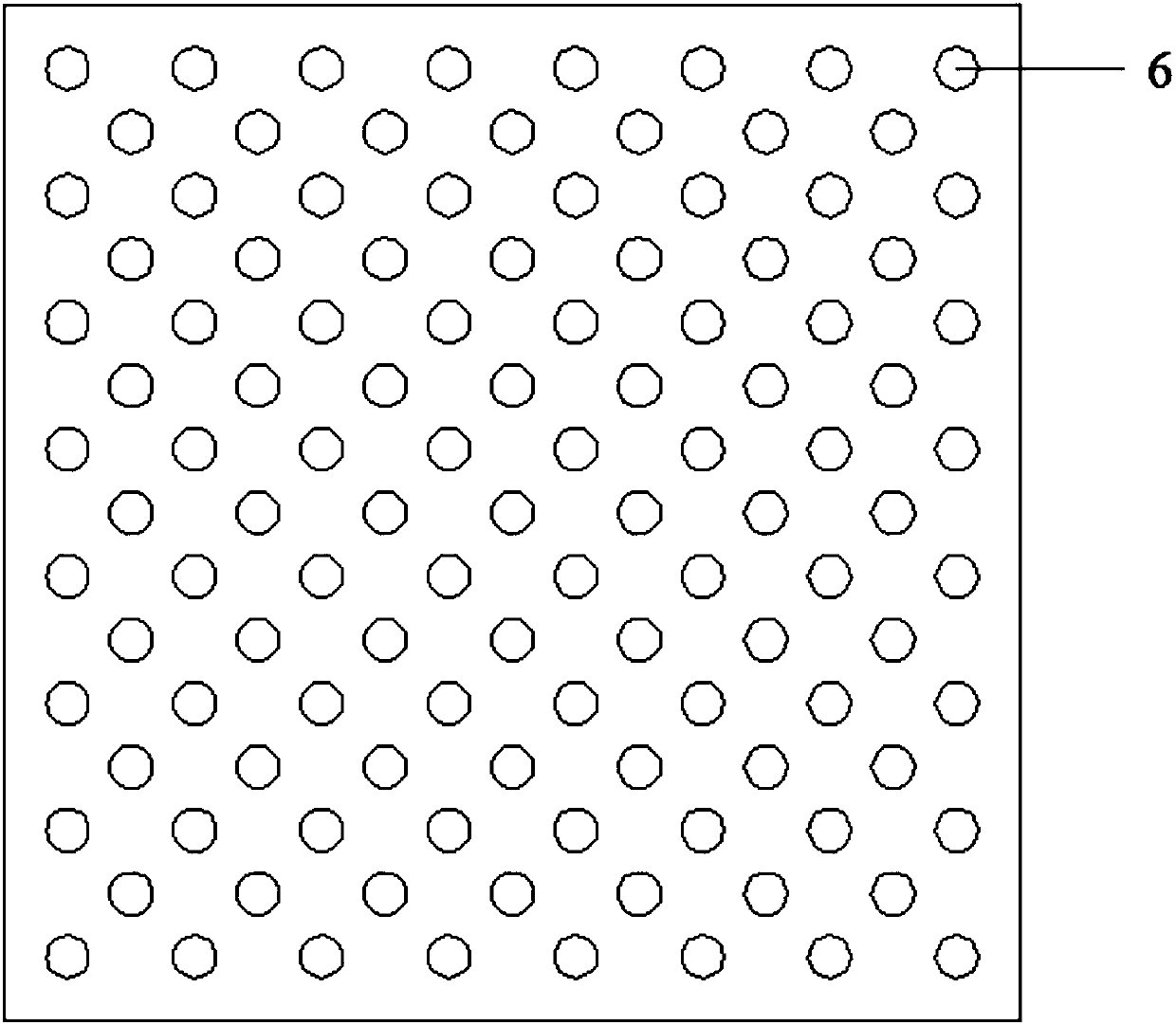

[0030] see figure 1 with figure 2 , the present embodiment provides a sewage infiltration tank, including a treatment system and an aeration system 2 arranged sequentially from top to bottom, the treatment system is filled with crushed stones 10 and fine sand 11, and the particle size of the crushed stones is 3-3. 4cm, the gravel filling thickness is 10cm, the gravel filling rate is 60%, the fine sand particle size is 0.1-2mm, the fine sand filling thickness is 10cm, and the fine sand filling rate is 60%. The aeration system is composed of 5 parallel aeration pipes, a number of circular holes are arranged at intervals on the aeration pipes, and the circular holes are arranged facing upwards, and the aeration pipes are located at the bottom of the sewage infiltration tank and are continuous from bottom to top. Aeration leads to more dissolved oxygen in the lower layer of the percolation tank and less dissolved oxygen in the upper layer. At the same time, aeration is beneficia...

Embodiment 2

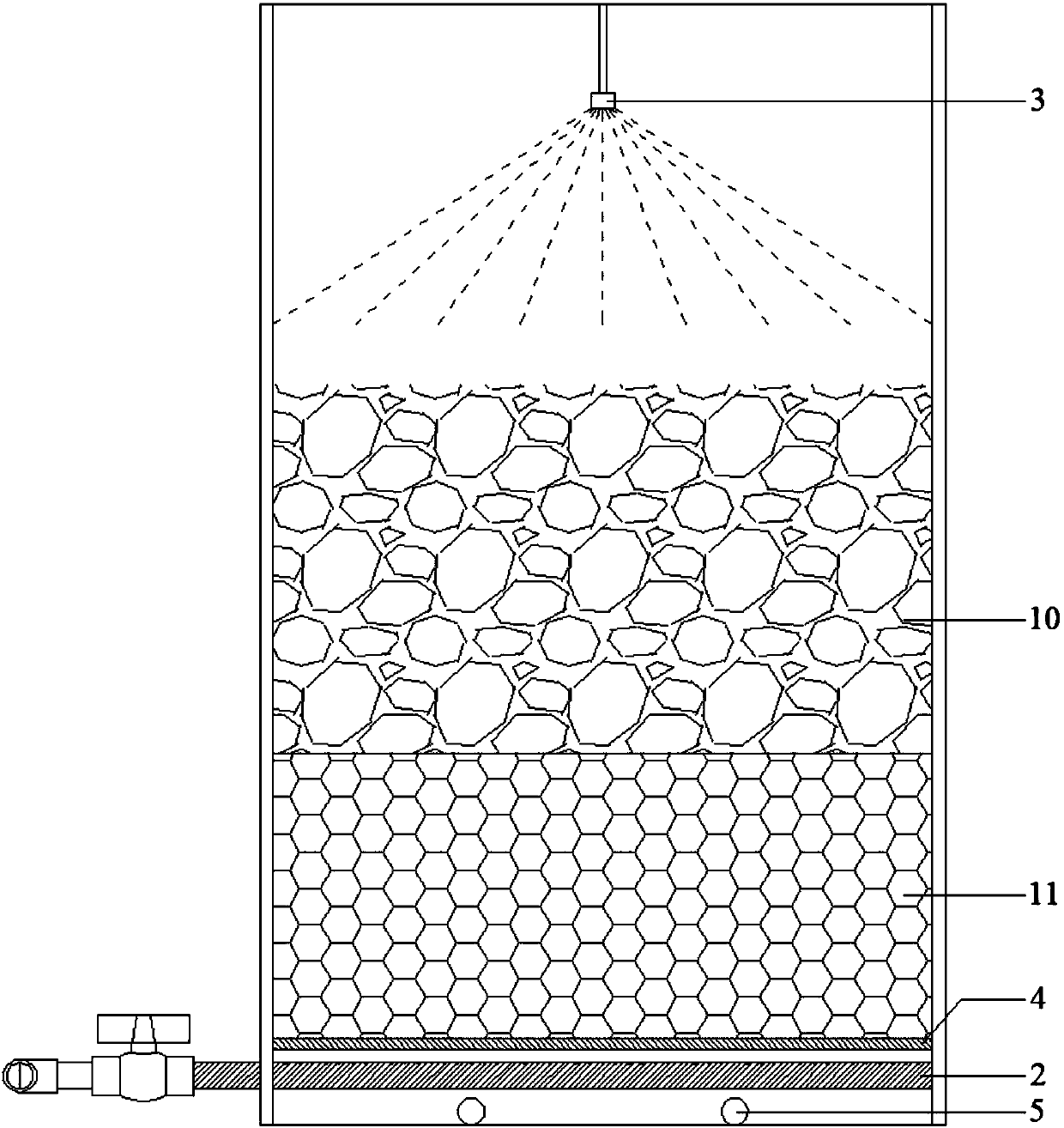

[0036] see Figure 4 with Figure 5 , the present embodiment provides a sewage infiltration tank, including a treatment system 1 and an aeration system 2 arranged sequentially from top to bottom, the treatment system 1 is filled with gravel 10 and fine sand 11, and the particle size of the gravel is 3-4cm, the gravel filling thickness is 50cm, the gravel filling rate is 40%, the fine sand particle size is 0.1-2mm, the fine sand filling thickness is 40cm, and the fine sand filling rate is 80%. The aeration system is composed of five parallel aeration pipes, the aeration pipes are located at the bottom of the sewage infiltration tank, and a number of round holes are arranged at intervals on the aeration pipes, and the round holes are arranged facing upward.

[0037] Preferably, the sewage infiltration tank of the present invention is also provided with a perforated water distribution pipe system above the treatment system 1, and the perforated water distribution pipe system con...

Embodiment 3

[0041] see Image 6 , This embodiment provides a sewage infiltration system, including the primary sedimentation tank 9 and the sewage infiltration tank in Embodiment 1. Sewage first passes through the primary sedimentation tank 9 to remove sinkable and floating matter, and then sprays it evenly on the gravel filler through the nozzle to make a layer of uniform biofilm grow on the filler. An aeration system is installed at the bottom of the sewage infiltration tank to continuously aerate The gas provides sufficient dissolved oxygen, and the oxygen fully contacts the sewage flowing downward from bottom to top, which improves the degradation rate of pollutants in the sewage, and finally the treated sewage flows out through the drain.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com