Method for repairing organic pollutants in farmland soil through combination of biochar and biodegradation

A technology of organic pollutants and combined biology, applied in the field of organic pollutant treatment, can solve problems such as limited application range, and achieve the effects of improving treatment effect, promoting anaerobic degradation, and promoting adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

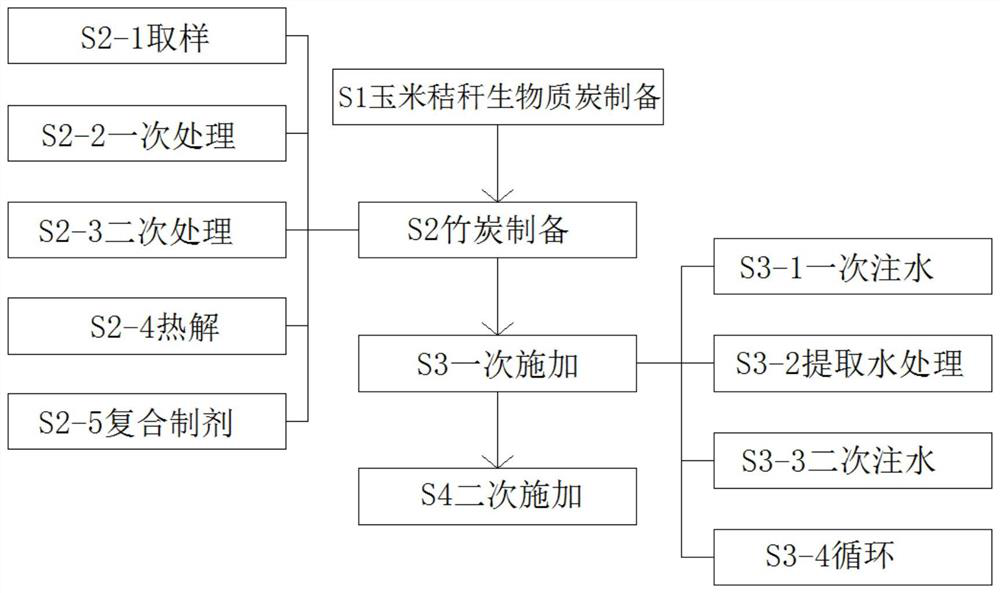

Method used

Image

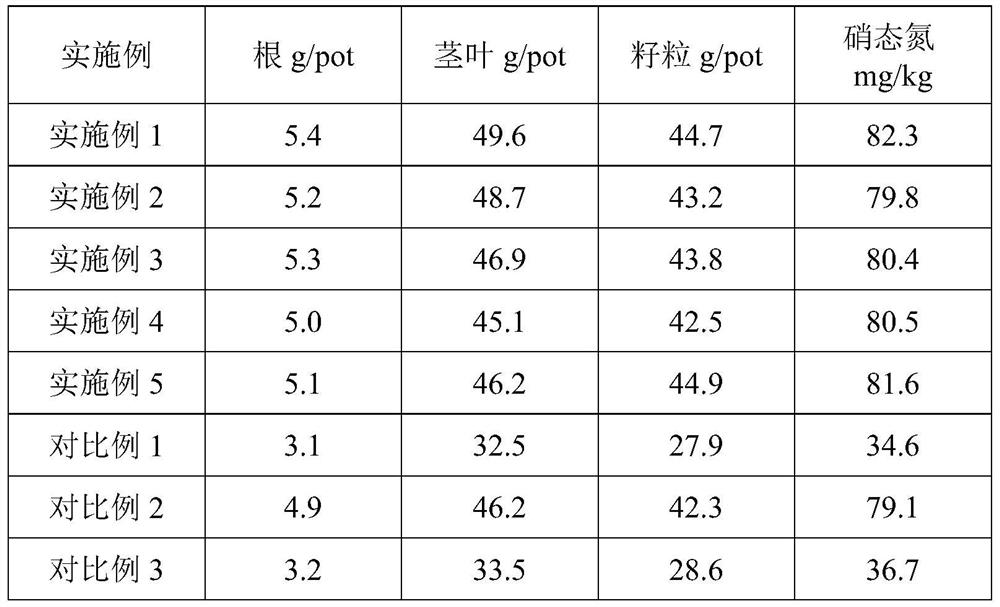

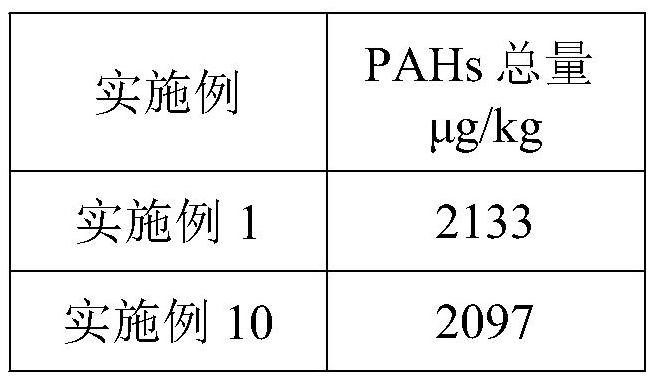

Examples

Embodiment 1

[0035] A method for biochar combined with biodegradation to restore organic pollutants in farmland soil, comprising the following steps:

[0036] S1. Preparation of corn stalk biochar: take corn stalks and expose them to the sun for 2 days, rinse them with distilled water for 3 times, and dry them in an oven for 8 hours at a temperature of 75°C. Use a pulverizer to crush them and pass them through a 70-mesh sieve. , Put the corn stalk powder in a tube furnace and heat it to 200°C at a heating rate of 13°C / min, keep it warm for 1h, then heat it to 300°C at a heating rate of 20°C / min, hold it for 2.5h, and cool to room temperature Finally, take it out, and use deionized water to rinse 3 times to obtain corn stalk biochar CB300;

[0037] S2. Bamboo charcoal preparation: wild alpine bamboo charcoal with a growth year of 4 years was naturally air-dried for 3 days, soaked in a biomass degradation solution for 18 hours, and the mass ratio of wild alpine bamboo to biomass degradation ...

Embodiment 2

[0047] This example is basically the same as Example 1, except that the preparation method of the corn stalk biochar in step S1 is different.

[0048] S1. Preparation of corn stalk biochar: take corn stalks and expose them to the sun for 2 days, rinse them with distilled water for 3 times, dry them in an oven for 6 hours at 70°C, crush them with a pulverizer, and then sieve them through a 60-mesh sieve. , Put the corn stalk powder in a tube furnace and heat it to 200°C at a heating rate of 10°C / min, hold it for 1 hour, then heat it at a heating rate of 20°C / min to 300°C, hold it for 2 hours, and cool it to room temperature Take it out, rinse with deionized water 3 times, and obtain corn stalk biochar CB300.

Embodiment 3

[0050] This example is basically the same as Example 1, except that the preparation method of the corn stalk biochar in step S1 is different.

[0051] S1. Preparation of corn stalk biochar: take corn stalks and expose them to the sun for 2 days, wash them with distilled water for 3 times, dry them in an oven for 10 hours at 80°C, crush them with a pulverizer, and then sieve them through an 80-mesh sieve. , Put the corn stalk powder in a tube furnace and heat it to 200°C at a heating rate of 15°C / min, hold it for 1 hour, then heat it at a heating rate of 20°C / min to 300°C, hold it for 3 hours, and cool it to room temperature Take it out, rinse with deionized water 3 times, and obtain corn stalk biochar CB300.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com