Bamboo powder coated paper

A technology of coated paper and bamboo powder, applied in the field of coated paper, can solve the problems of poor mechanical properties and thermal stability, high price, etc., achieve a wide market prospect, improve low strength, improve bending strength and flexural modulus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

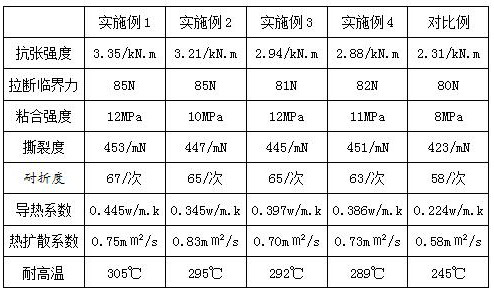

Examples

Embodiment 1

[0016] A kind of bamboo powder coating paper, described coating paper comprises base paper and coating layer, the preparation composition of described coating layer comprises bamboo powder and degradable plastic; The composition of described degradable plastic comprises polylactic acid, polybutylene Butylene glycol ester, copolymer with butylene adipate and butylene terephthalate.

[0017] The preparation ingredients of the coating layer include by weight percentage: 20% polylactic acid, 20% polybutylene succinate, 40% copolymer with butylene adipate and butylene terephthalate. % and bamboo powder 20%.

[0018] The preparation method of the bamboo-plastic composite material corresponding to the coating liquid in the present embodiment comprises the following steps:

[0019] 1) Put the bamboo powder in a drying oven at 100 °C for 24 h;

[0020] 2) Then put the three kinds of degradable plastic particles and bamboo powder into the internal mixer and mix for 10 minutes, the tem...

Embodiment 2

[0023] A kind of bamboo powder coating paper as described in embodiment 1, wherein coating layer can also adopt following scheme:

[0024] The preparation ingredients of the coating layer include by weight percentage: 15% of polylactic acid, 25% of polybutylene succinate, and a copolymer of butylene adipate and butylene terephthalate 35%% and bamboo powder 25%, other raw materials 0%.

Embodiment 3

[0026] A kind of bamboo powder coating paper as described in embodiment 1, wherein coating layer can also adopt following scheme:

[0027] The preparation ingredients of the coating layer include by weight percentage: 25% polylactic acid, 15% polybutylene succinate, 45% copolymer with butylene adipate and butylene terephthalate. % and bamboo powder 15%, other raw materials 0%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com