Crosslinked laminated wrapping film and container box therefor

A technology of packaging film and cross-linked layer, which is applied in the field of food packaging film and cross-linked laminated polyethylene packaging film, can solve the problems of not being able to optimize the film material or composition and cutter combination, and balance difficulties, and achieve excellent Adhesive properties, low flexibility, and the effect of excellent appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-3

[0258] Embodiment 1-3, comparative example 1, comparative example 6

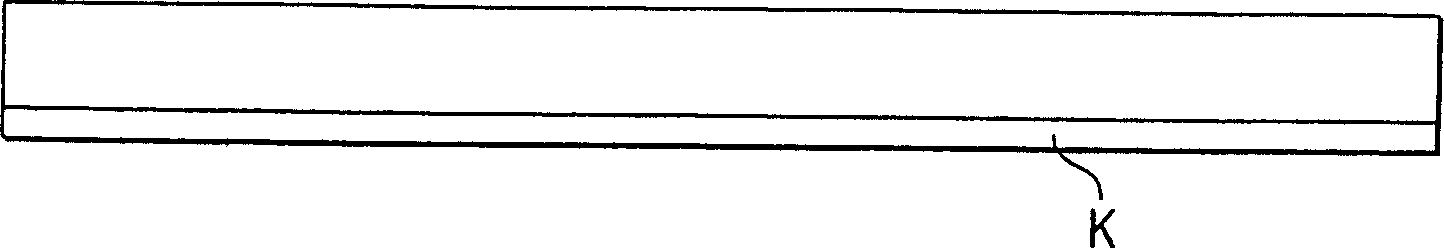

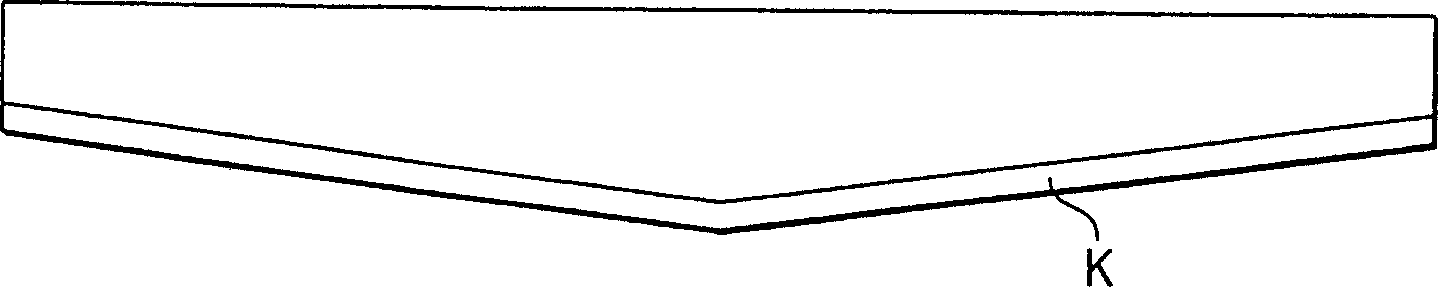

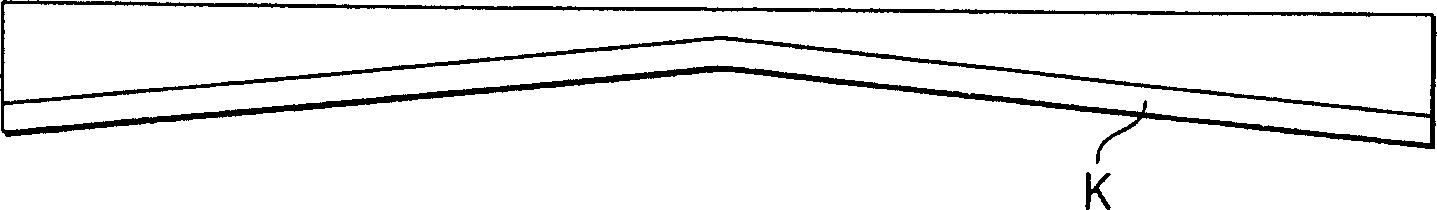

[0259] A three-layer laminated film having a surface layer / intermediate layer / surface layer ratio of 15 / 70 / 15 was prepared using the above preparation procedure. In this preparation process, 50 wt% of "Attaine 4201" (trade name; linear low-density polyethylene), 50 wt% of "Petrothene 186R" (high-pressure processed low-density polyethylene) and 0.800 parts by weight of "Rikemal OL-100E" were used for the surface layer. (trade name; glycerol monofatty acid ester), the middle layer uses 75 wt% of "Suntec HD S360" (trade name; high-density polyethylene), 25 wt% of "Suntec LD M2004" high-pressure processing low-density polyethylene and 0.800 Parts by weight of "Rikemal OL-100E" (trade name; glycerol monofatty acid ester) (Example 1). In order to determine the impact of the additive, the glycerol monofatty acid ester consumption in the surface layer and the middle layer is changed into 0.500 weight part (embodime...

Embodiment 4 and 5

[0260] Embodiment 4 and 5, comparative example 2 and 3

[0261] A packaging film was prepared in a manner similar to Example 2, except that the resin mixing ratio of the middle layer was changed to 90 wt% high-density polyethylene and 10 wt% high-pressure processed low-density polyethylene (Example 4). The ratio of interlayer HDPE / HPLDPE was changed to 50 / 50 (Example 5), 100 / 0 (Comparative Example 2) and 40 / 60 (Comparative Example 3). The resulting film data comprising the resin composition are listed in Tables 1 and 5. As a result, it was found that the packaging films of Examples 4 and 5 satisfied various performance requirements and thus were excellent packaging films, whereas Comparative Examples 2 and 3 were insufficient in tensile modulus. The results are listed in Tables 3 and 6.

Embodiment 6 to 9

[0262] Examples 6 to 9, Comparative Examples 4 and 5

[0263] A packaging film was prepared in a similar manner to Example 2, except that the resin mixing ratio of the surface layer was changed to 85 wt% linear low density polyethylene and 15 wt% high pressure processed low density polyethylene (Example 6). Change the ratio of surface layer linear low density polyethylene / high pressure processing low density polyethylene into 75 / 25 (embodiment 7), 60 / 40 (embodiment 8), 40 / 60 (embodiment 9), 100 / 0 ( Comparative Example 4) and 15 / 85 (Comparative Example 5). The resulting film data comprising the resin composition are listed in Tables 1 and 5. As a result, it was found that the packaging film of Example 6 was an excellent packaging film, and the films of Examples 7 to 9 met a variety of necessary properties of packaging films, so they were excellent packaging films. However, the adhesion energy and pull-out force of Comparative Examples 4 and 5 (These two properties are importa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com