Ultra-deep hole precision boring tool

An ultra-deep hole and tool technology, applied in boring bars, manufacturing tools, boring/drilling, etc., can solve the problems of not meeting the requirements of normal distribution of hole machining quality, difficult to control the machining quality, and difficult to effectively process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

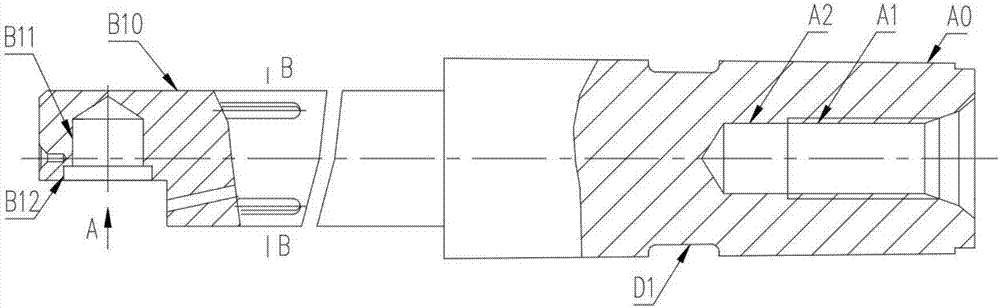

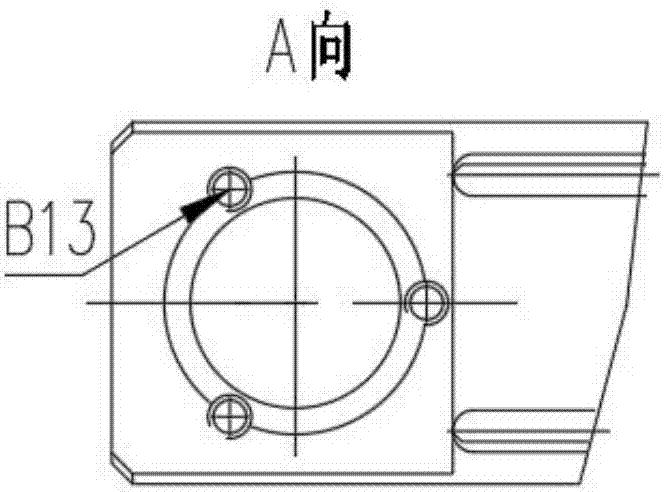

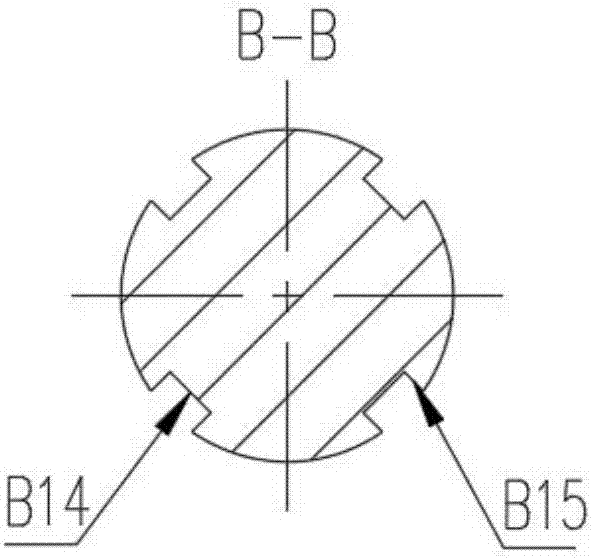

[0109] Implementation method: the guide hole of the workpiece guide seat When designing parts, leave a machining allowance of 0.5 to 0.8 mm for final assembly and use a five-axis machining center for alignment and finishing. If the tooling used by the lathe is designed, it is necessary to perform rough boring, fine boring, fine reaming, grinding and polishing on the tooling machine tool to ensure that the guide hole The size is 0.002-0.005mm larger than the rotation diameter of the wear-resistant support block 2 .

[0110] 3. How to use the ultra-deep hole indexable compound precision boring tool with guide bar

[0111] The method of using the deep hole indexable compound precision boring tool: when processing a high-precision through hole or blind hole with a length-to-diameter ratio greater than 8 times, first use the drilling tool to drill or ream the hole, Leave a margin of 1.5-2mm on both sides of the hole diameter, and then process it with a deep hole indexable reami...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com