Method for producing glass film

A manufacturing method and glass film technology, applied in glass manufacturing equipment, glass molding, glass molding, etc., can solve the problems of thickness change, variable size, uneven thickness, etc., and achieve the effect of stable flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Hereinafter, embodiments of the present invention will be described in detail with reference to the drawings.

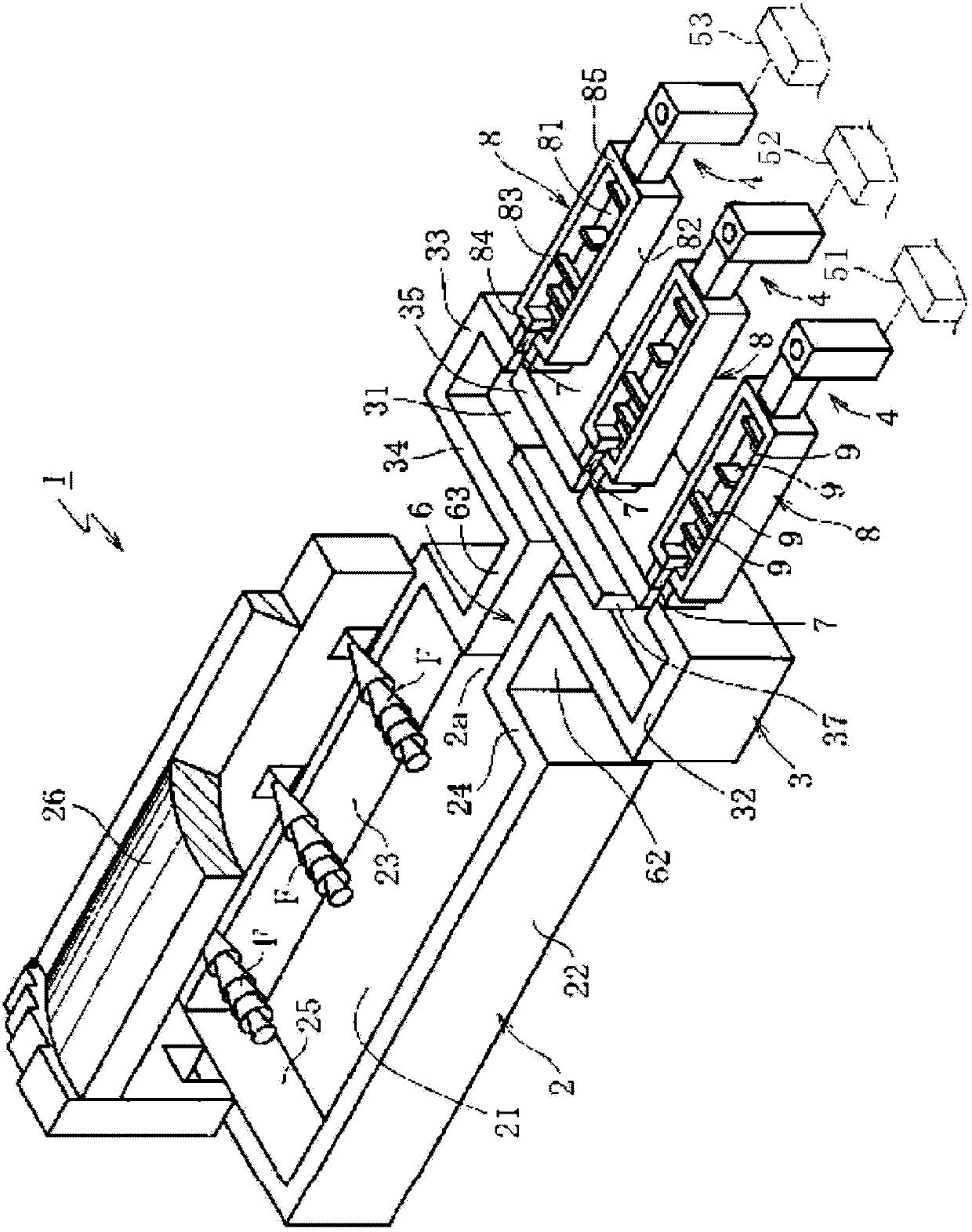

[0027] First, refer to figure 1 The whole structure of the molten-glass supply facility which concerns on embodiment of this invention is demonstrated. This molten glass supply facility 1 has a substantially rectangular melting furnace 2 constituting a supply source of molten glass, a distribution chamber (distribution portion) 3 communicating with the outflow port 2 a of the melting furnace 2 , and a downstream side end portion of the distribution chamber 3 . The plurality of branch flow paths 4 communicated at approximately equal intervals, and the downstream end portions of the branch flow paths 4 communicate with the plurality of molding devices 51 to 53 , respectively. It should be noted that there are three paths to the molding devices 51 to 53 through the branch channel 4 in the figure, but there may be two paths, or four or more paths.

[0028] The m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com