Crust-type high-elongation low-smoke halogen-free flame-retardant polyolefin cable material and preparation method thereof

A technology of polyolefin cable material and high elongation, which is applied in the direction of circuits, electrical components, plastic/resin/wax insulators, etc. It can solve the problems of poor material flexibility and poor dispersion of inorganic powders, so as to prevent chimney effect, The effect of preventing the flame from penetrating into the cable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

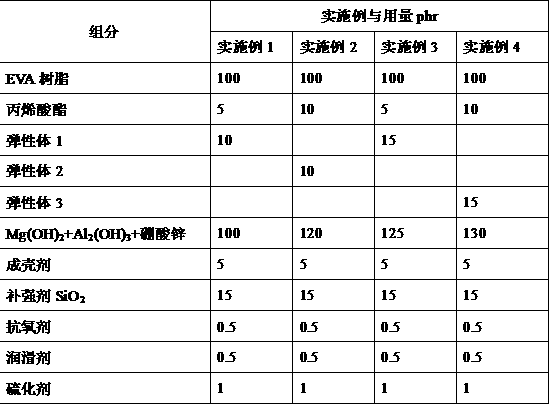

[0015] Below in conjunction with embodiment the present invention is further described.

[0016] Raw material performance in the embodiment of the present invention:

[0017] Ethylene-vinyl acetate copolymer (EVA resin): MFR at temperature 190 o C, 1 g / 10min under the test condition of load weight 2.16 Kg;

[0018] Ethylene acrylate: the number of parts of methyl acrylate in the copolymer is 20 parts, and the MFR is at a temperature of 190 o C, 3 g / 10min under the test condition of load weight 2.16Kg;

[0019] Mg(OH) 2 : The particle size is 1.5 μm;

[0020] Al(OH) 3 : The particle size is 2.0 μm;

[0021] Zinc borate: particle size is 2.0 μm;

[0022] Microencapsulated red phosphorus: the particle size is 5-10 μm. Purple-red powder, relative density 2.1, bulk density 0.6g / cm3;

[0023] Ammonium polyphosphate: fineness (through 50μm sieve) / %≥ 90

[0024] SiO 2 : It is fumed white carbon black with a particle size of 0.5 μm;

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com