Elastomeric balloon support fabric

A technology for elastic fabrics and balloon catheters, applied in the field of manufacturing such fabrics, elastomer sleeves or balloon covers, can solve the problems of increasing the volume of the cover, less edges and corners, and limiting the flexibility of the balloon, and achieves increased volume, good elastic balance, and improved reproducibility. walkthrough effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0097] Table II Fabric Design Calculated Values

[0098] Variable Unit Value Variable Name Formula

[0099] Minimum sleeve diameter mm 1.0 Dmin = d*100 / e

[0100] Circumferential Stress lb / in 22.4 Sh =(p*d / 2) / 25.4

[0101] Longitudinal Stress lb / in 11.2 Sa = Sh / 2

[0102] Circumferential strength / yarn lb .128 Syh = gpd*denY*eff / 454

[0103] Machine direction tenacity / yarn lb .357 Sya = gpd_w*denY_w*eff_w / 454

[0104] Minimum yarn / inch-circumferential (maximum 1 / inch 175 Yh = Sh / Syh

[0105] diameter)

[0106] Minimum yarn / inch - machine direction (maximum 1 / inch 31 Ya = Sa / Sya

[0107] diameter)

[0108] The minimum number of axial directions on the braid 15 Na =Ya*d*pi(π) / 25.4

[0109] yarn

[0110] Knitting yarn (circumferential direction)

[0111] Yarn Diameter (Solid Rod Equivalent) inches .0041 Dys = .000468*SQRT(denY / rho)

[0112] Yarn diameter (circle equivalent) inches .0041 Dy = Dys / SQRT(phi)

[0113] Yarn Thickness inches .0041 Ty = Dy / SQRT(a)

[0114]...

example 3

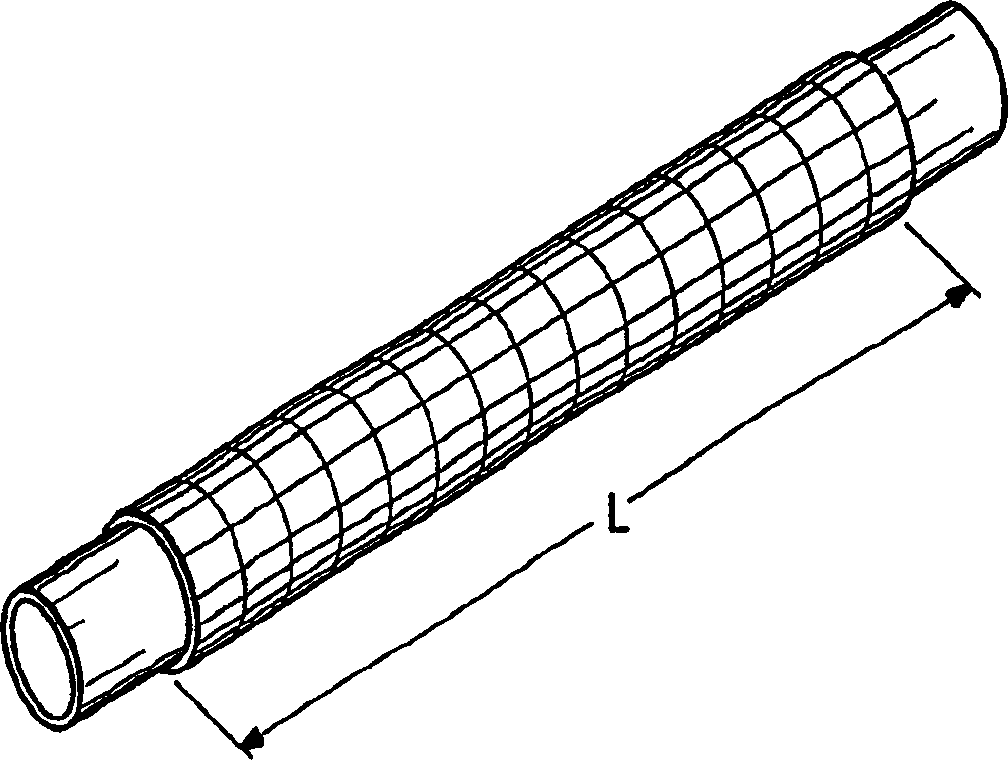

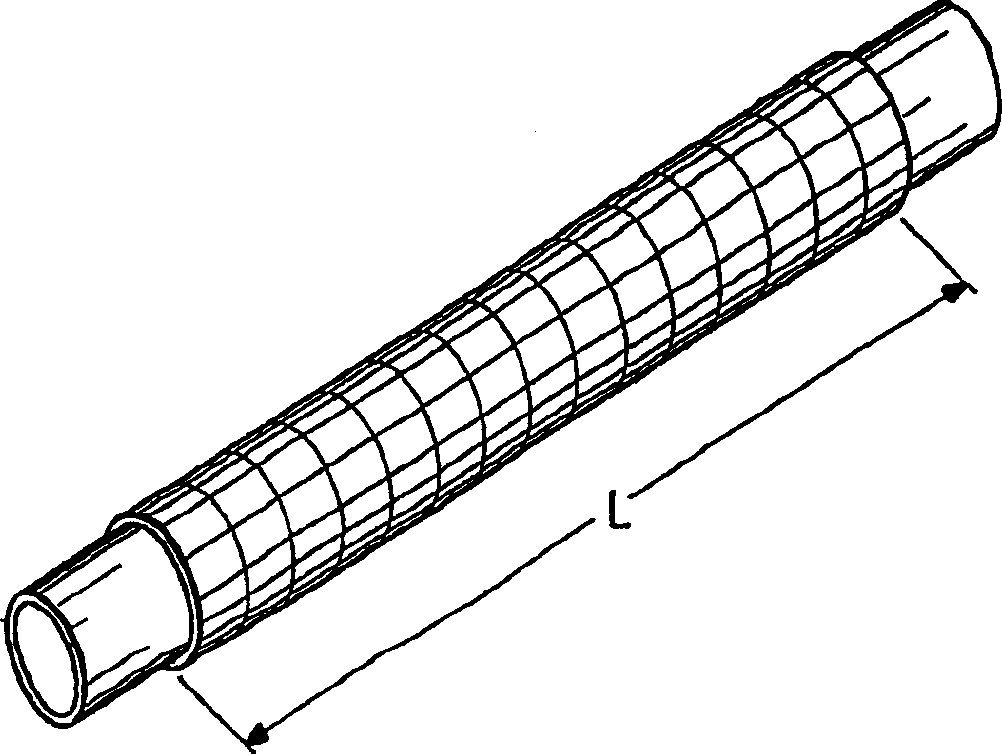

[0201] Example 3 Method of Braiding Elastic Fabric Directly on Inflatable Balloon Catheter

[0202] fabric description

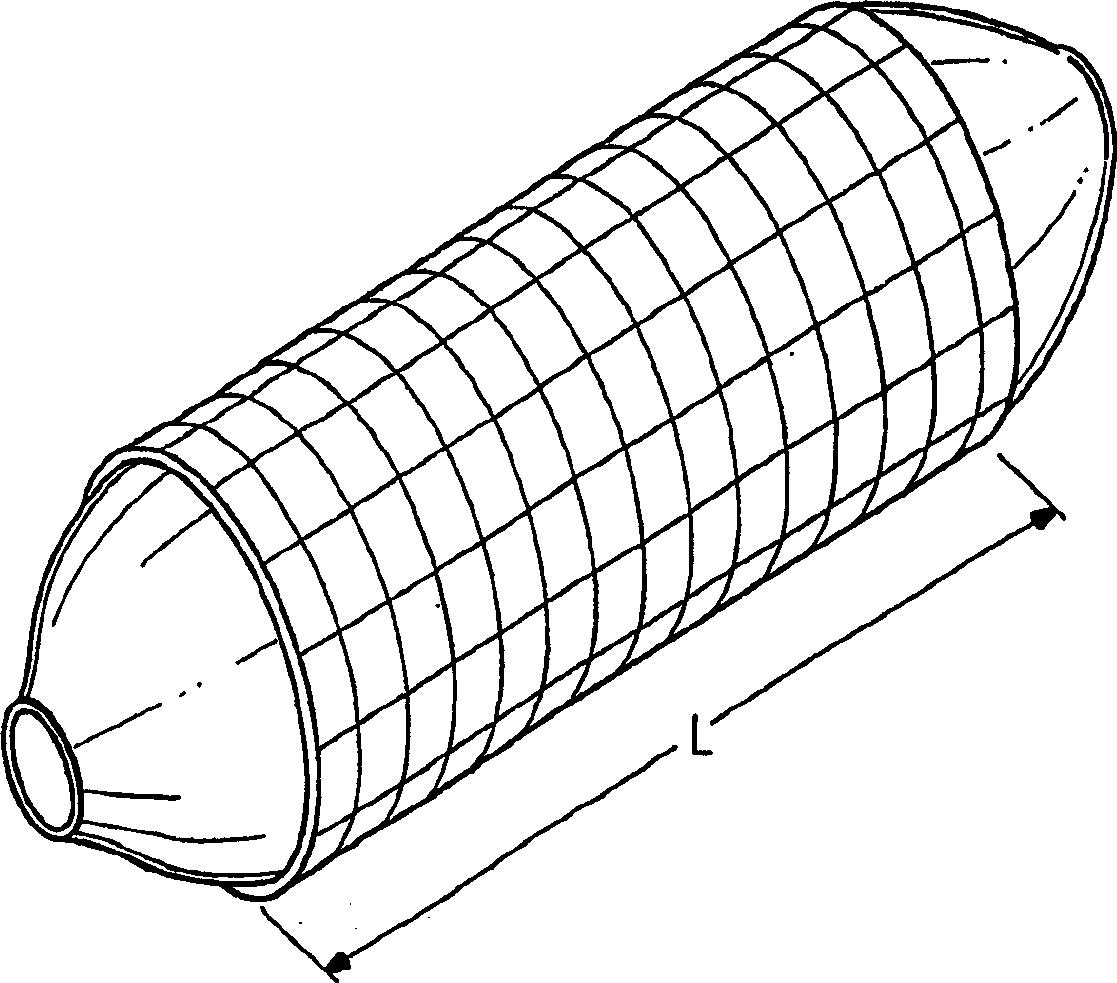

[0203] The yarns in this fabric are woven into tubular geometric shapes. 16 axial yarns are arranged longitudinally and these yarns are interwoven with 2 braiding yarns. The weaving yarns lie on opposite helical paths, the weaving yarns being nearly perpendicular to the longitudinal axis. There are approximately 254 braiding yarns per inch of tube length. The diameter of the braid varies between about 1-4 mm depending on the internal pressure, while the length of the braid remains substantially constant.

[0204] yarn material

[0205] The axial yarns consisted of polyester fibers (40 denier, 27 filaments). These yarns are generally inextensible with an elongation to break of 27%. On the other hand, the braided yarn is composed of highly elastic fibers with a breaking elongation of 600%.

[0206] Highly elastic fiber yarns have high recovery from any ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com