Rail vehicle for a driving operation on track systems having a ballasted superstructure

A rail vehicle and ballast technology, applied in the field of rail vehicles, can solve the problem of not being able to effectively prevent icing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

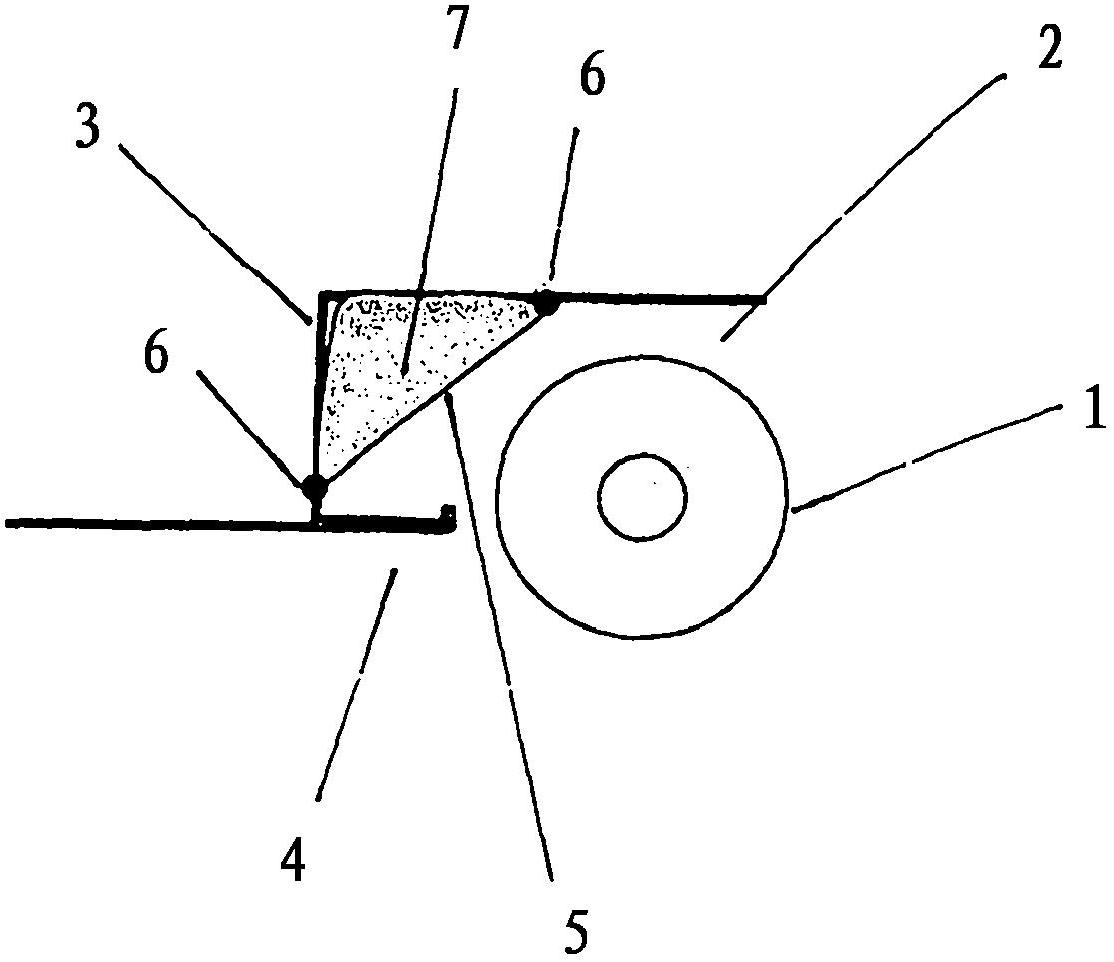

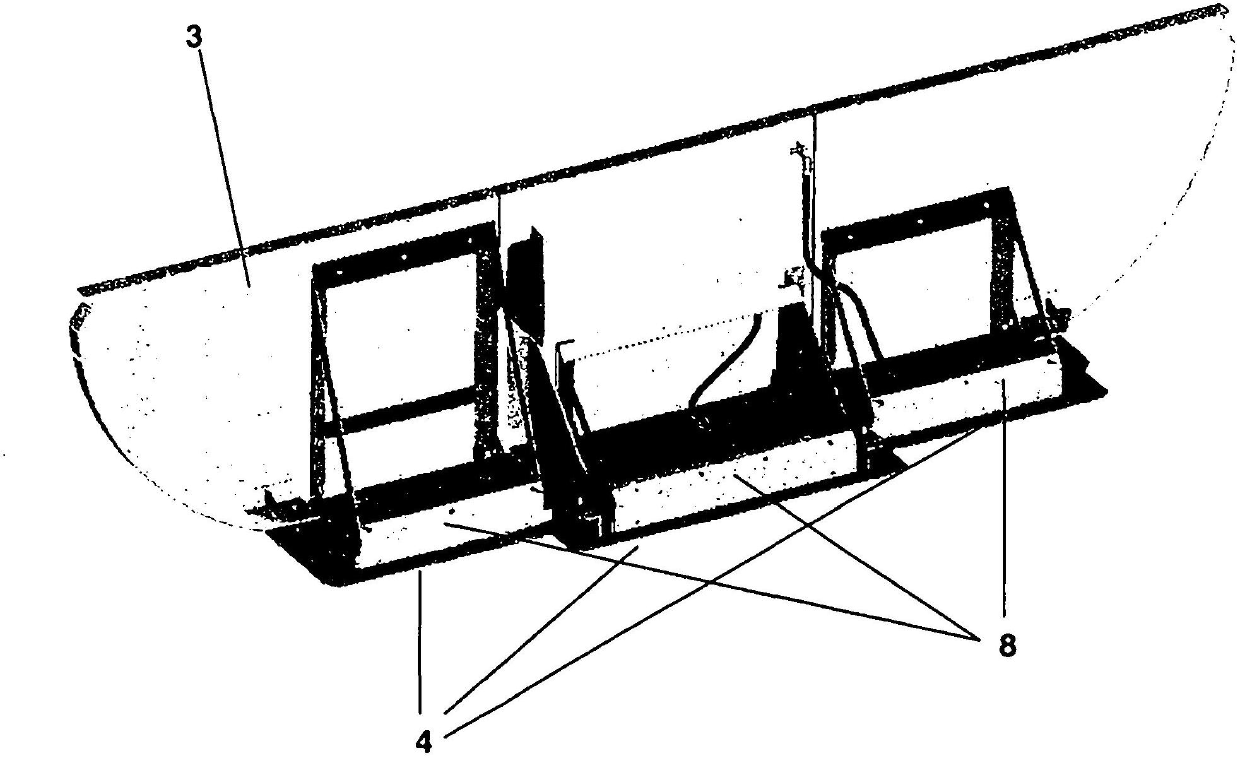

[0019] exist figure 1 A bogie free space ( 2 ) of a rail vehicle with a diaphragm ( 5 ) fastened to a fastening point ( 6 ) according to the invention is schematically shown in FIG. The membrane is here arranged transversely to the direction of travel of the rail vehicle and in particular covers the corner recess formed by the partition wall ( 3 ) and the cover plate of the bogie free space. The inclined arrangement of the membrane in combination with the hydrophobic coating on the outside of the membrane supports the sliding or falling of snow or ice that accumulates on the membrane. The interspace between the diaphragm and the bulkhead or cover plate of the bogie free space is equipped with a volume-variable shaped body (7).

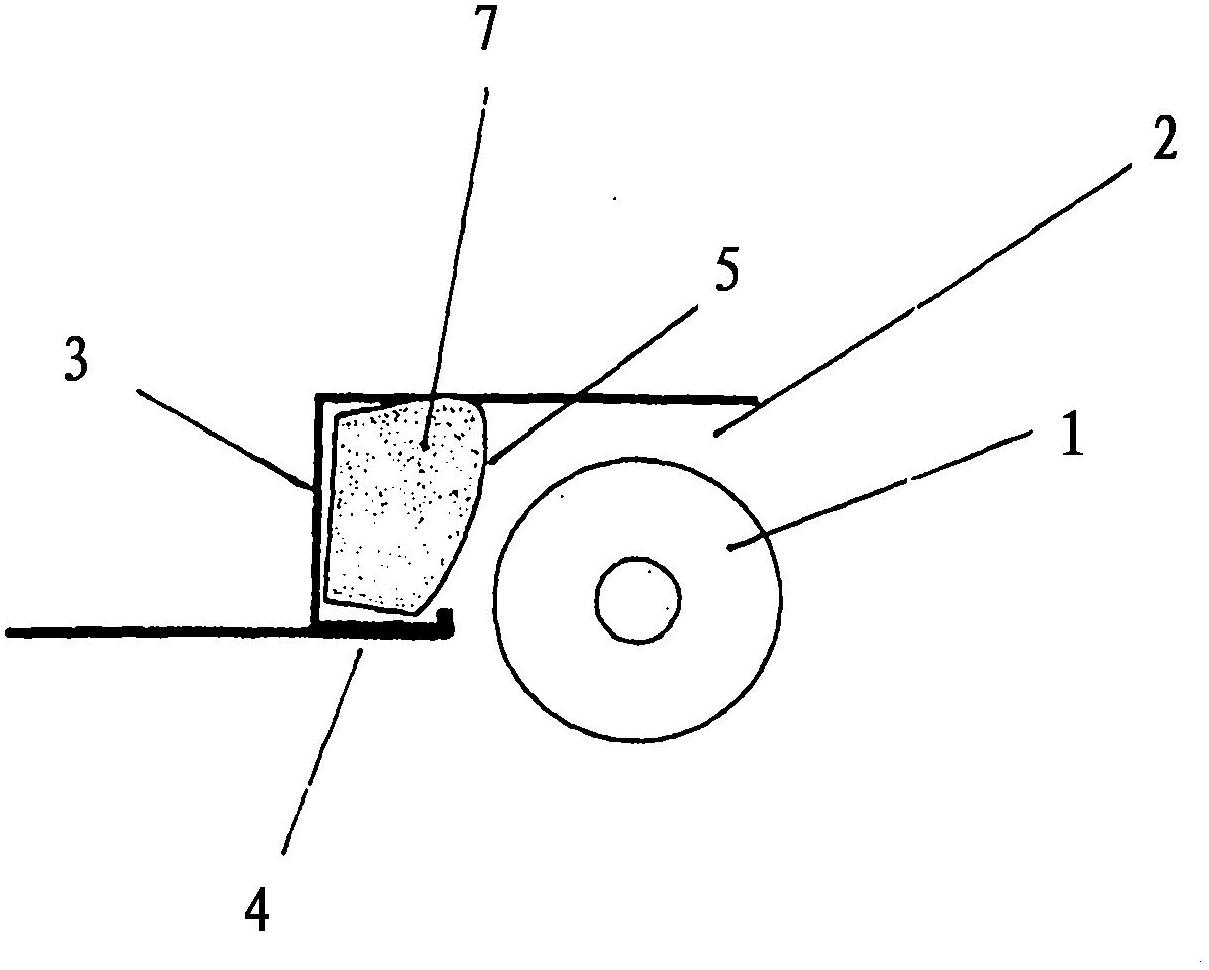

[0020] exist figure 2 The bogie free space ( 2 ) of a rail vehicle according to the invention is schematically shown with a membrane ( 5 ) applied to the outer surface of a deformable three-dimensional body ( 7 ). In this exemplary embodiment, an o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com