Easy-to-disassemble type single-stage single-suction vertical centrifugal pump

A vertical centrifugal and centrifugal pump technology, applied in the field of centrifugal pumps, can solve the problems of increased flexibility of the pump shaft, long time-consuming, high cost, etc., and achieve the effects of reducing impeller wear, increasing service life, and improving volumetric efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

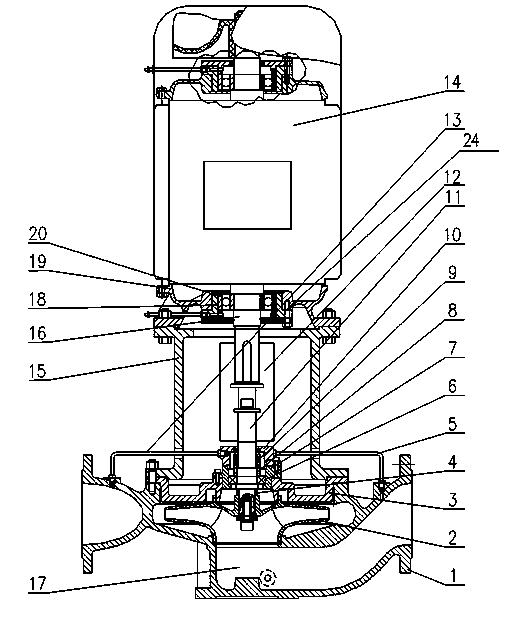

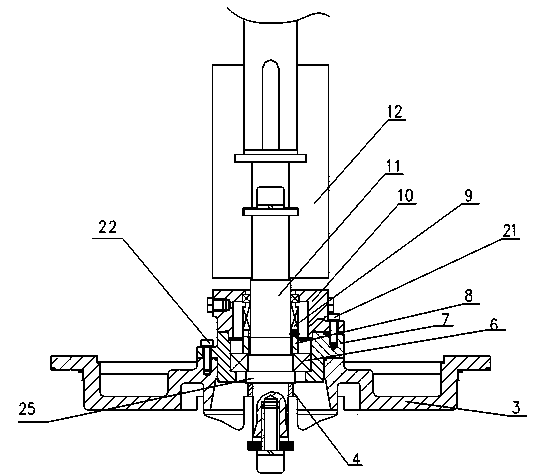

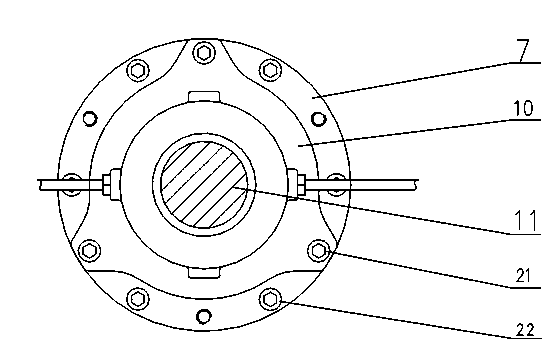

[0025] The preferred embodiments of the present invention are given below in conjunction with the accompanying drawings to describe the technical solution of the present invention in detail.

[0026] like Figure 1 to Figure 3 As shown, the detachable single-stage single-suction vertical centrifugal pump of the present invention includes a pump shaft 11, a coupling 12, and a motor shaft 16, and the pump shaft 11 and the motor shaft 16 are connected by a coupling 12, and the coupling Device 12 is a clamshell coupling. The present invention adopts the clamshell coupling to disassemble other components conveniently, and leaves a distance between the motor shaft and the pump shaft, so that the mechanical seal gland, the bearing body and other components can be taken out.

[0027] Both the pump shaft and the motor shaft are an independent component, that is, the pump shaft and the motor shaft no longer use the same shaft, so that the pump shaft can be made of suitable materials to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com