Conveyor chain

A technology of chains and transmission systems, applied in the field of bolt chains or pin chains, can solve problems such as wear and tear of central links

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

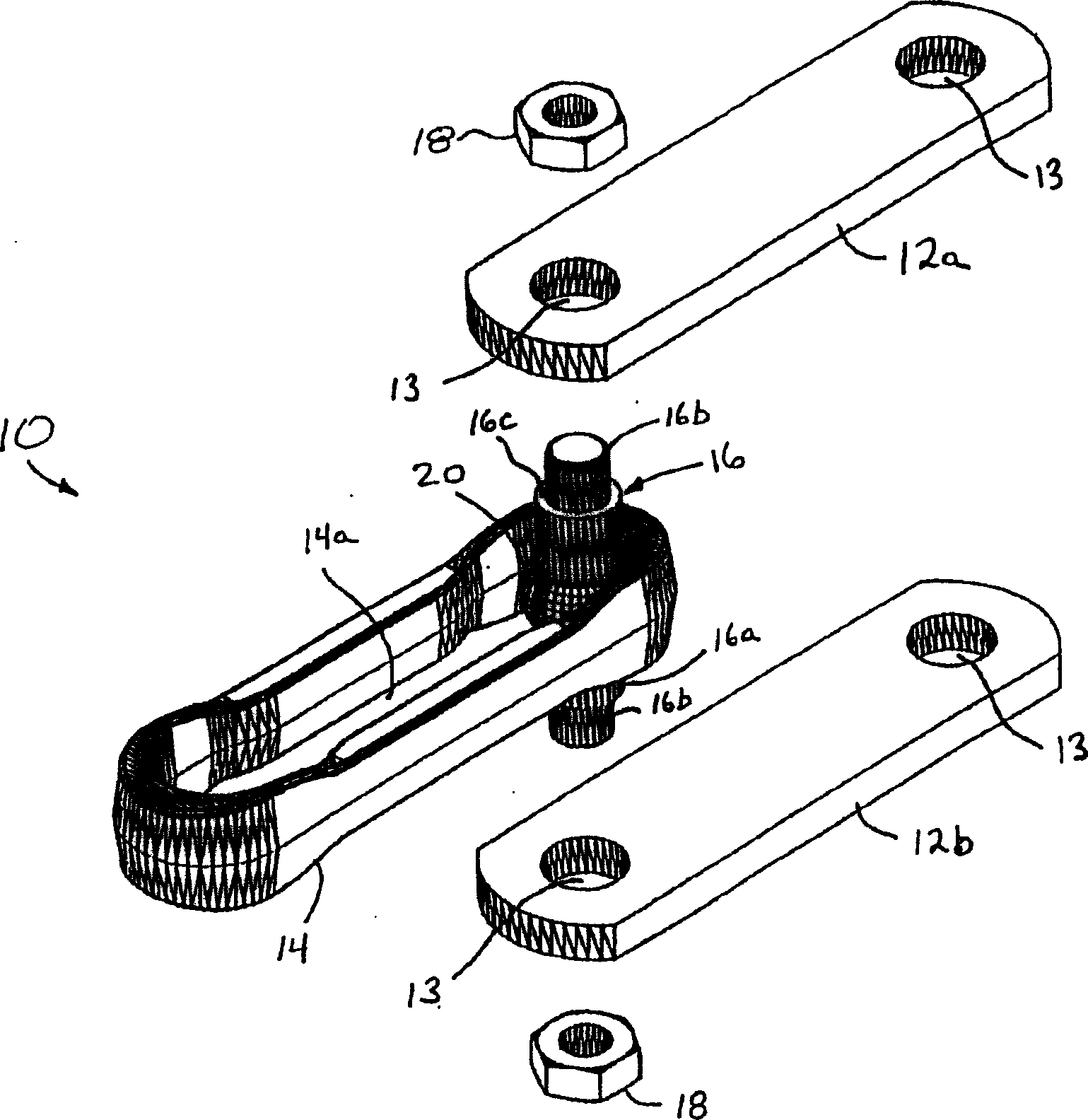

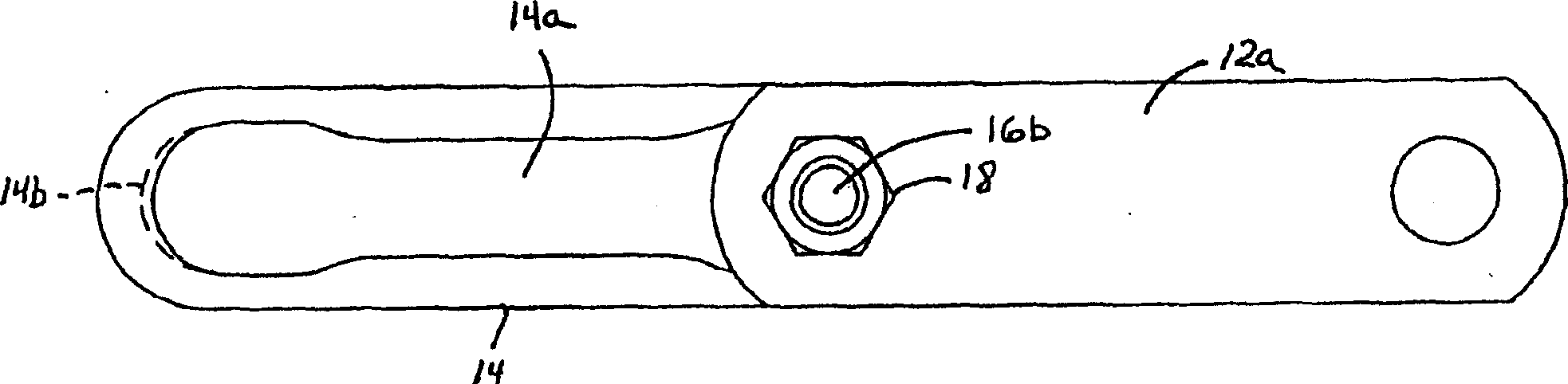

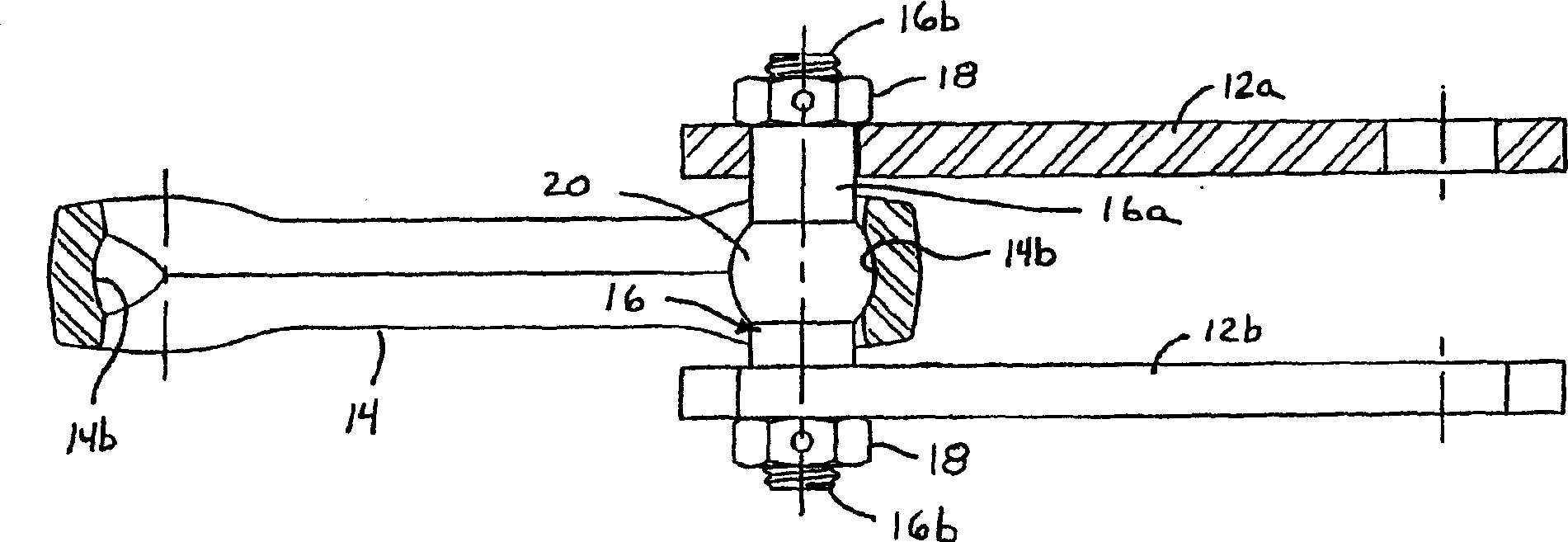

[0069] Referring now to the drawings and illustrating embodiments, a chain section 10 for transporting products along a transport system, such as a material handling or handling system, includes a pair of side links 12a, 12b and a center link 14 ( Figure 1-3 ). The central link 14 is held between the side links 12a, 12b by a stud or stud-type pin 16 which extends through the central region 14a of the central link 14 and into each side link 12a, 12b. The opening 13 of the opening 13 is held in it by a corresponding fixing piece or nut 18. The stud 16 includes a spherical or annular spherical member 20 generally seated at the midpoint and intermediate region of the shaft portion 16 a of the stud 16 . The chain 10 comprises a plurality of links connected together in a continuous loop around the conveyor system, as is known in the art. To simplify the description, only one group or part of the chain connections are shown, and the other chain connections are basically the same. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com