Wire harness waterproof structure

A technology of waterproof structure and wiring harness, which is applied in the direction of cables, insulated conductors, cable terminals, etc., and can solve problems such as corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

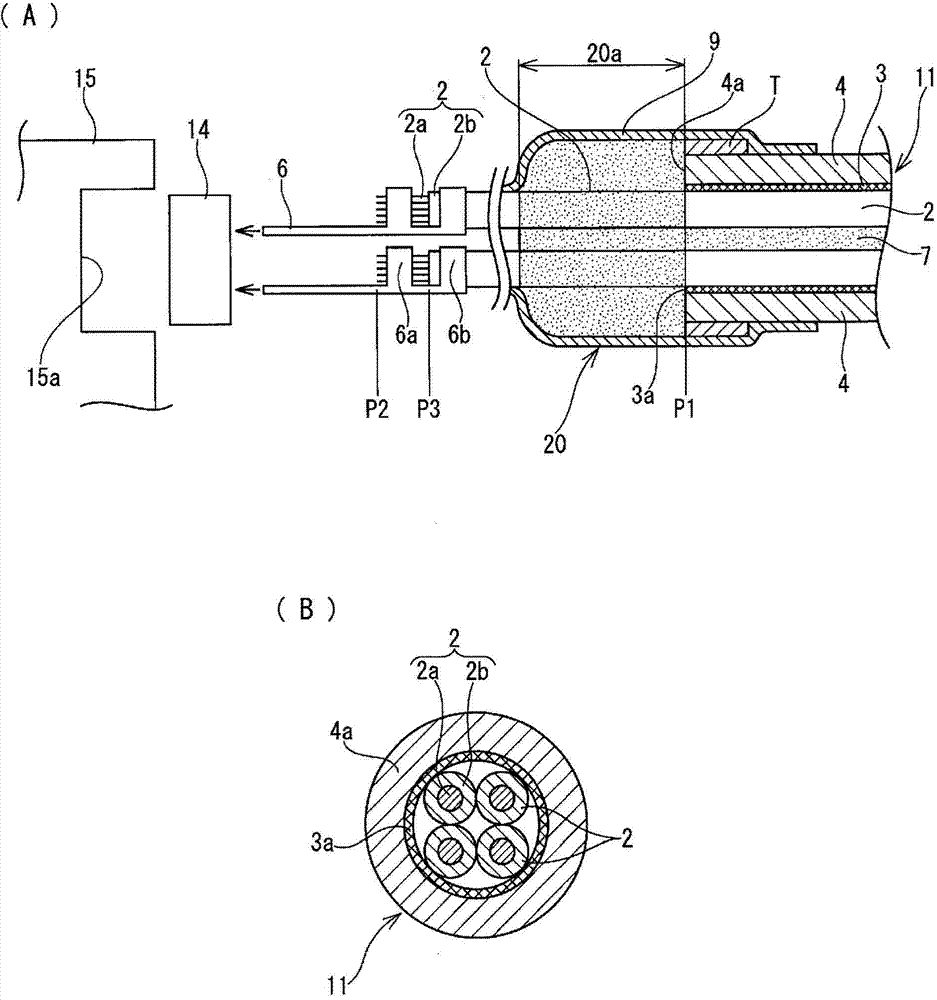

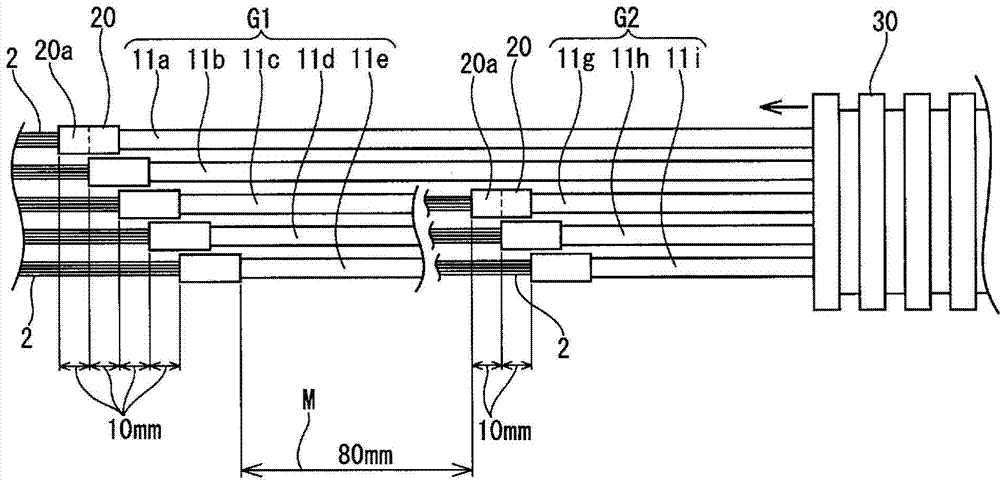

[0038] Embodiments of the present invention are described below with reference to the drawings.

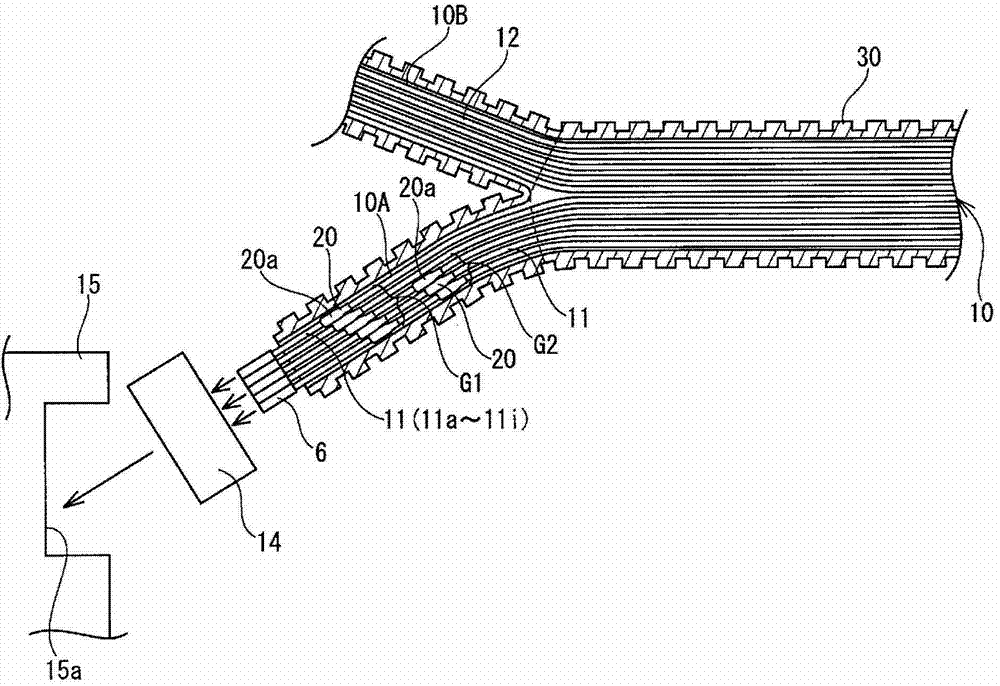

[0039] figure 1The wire harness 10 shown in is routed in the engine room of the car, which is an area exposed to water. A bundle of wires constituting the wire harness 10 includes a plurality of shielded wires 11 (eight wires in the present embodiment). The wire bundle includes electric wires 12 in addition to shielded wires 11 . On one end of the wire harness 10, terminals of eight shielded wires 11 are connected to a waterproof connector 14 connected to a connector fitting portion 15a of an ECU (Electronic Control Unit) 15 installed in the engine room . Another waterproof connector (not shown in the drawings) is connected to a normal electric wire 12 other than the shielded wire 11 . Specifically, one end portion of the wire harness 10 is branched into a branch wire 10A in which the eight shielded wires 11 are bundled and a branch wire 10B of another wire bundle.

[0040] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com