Simple coaxial calorimeter

A calorimeter and coaxial technology, applied in the field of high heat flux measurement devices, can solve the problems that the steady-state calorimeter is difficult to withstand for a long time, the processing requirements are high, and the development of heat flux sensors cannot meet the requirements of aircraft development.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

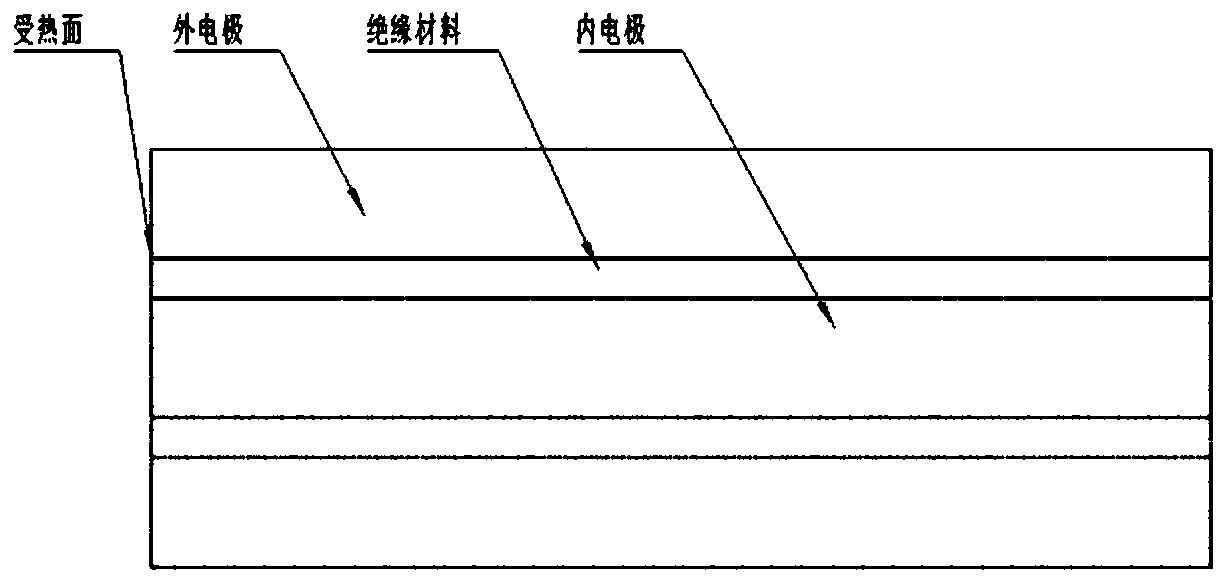

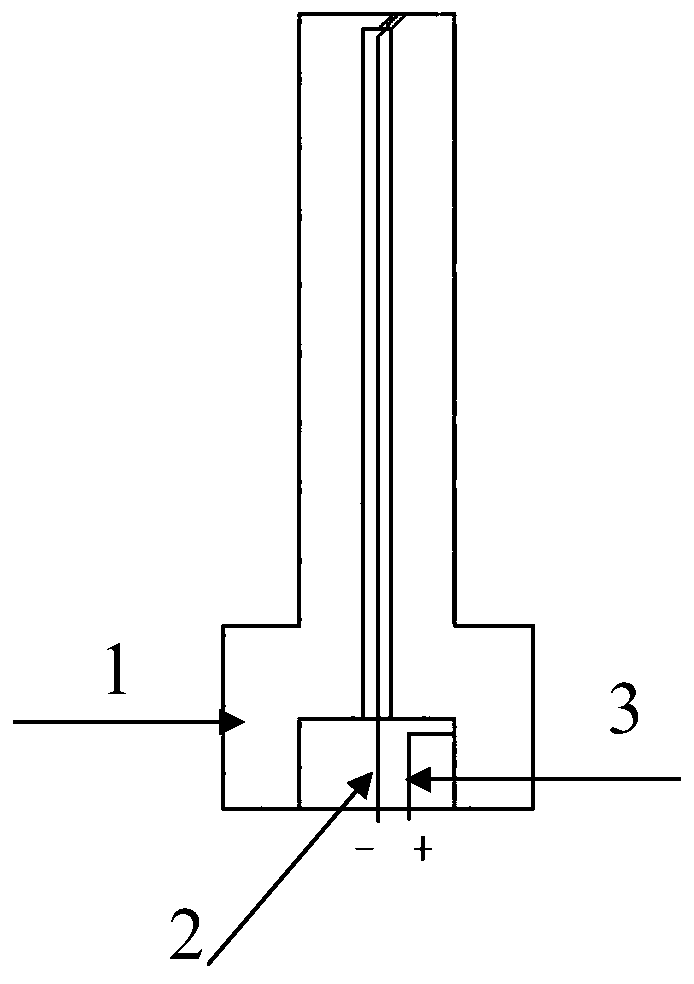

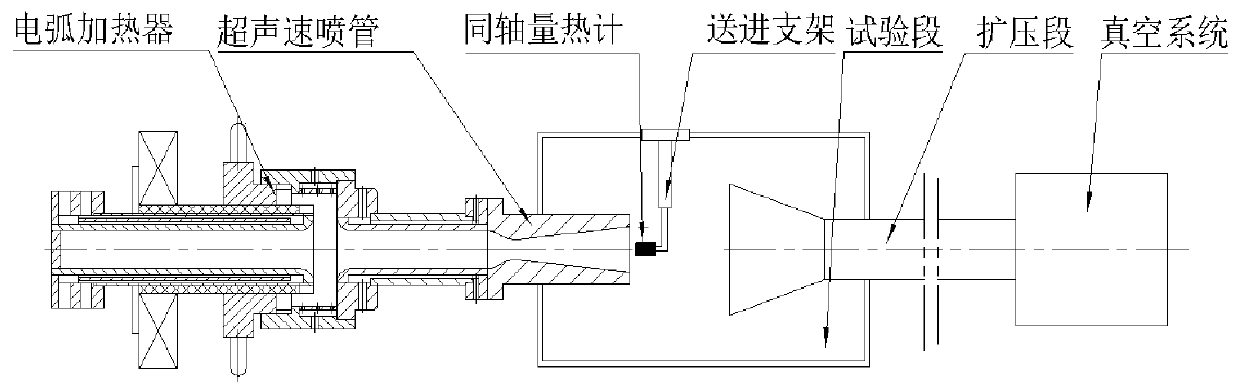

[0014] Such as figure 2 As shown, a novel coaxial calorimeter of the present invention mainly includes a coaxial calorimeter housing 1, a constantan wire 2 with an insulating layer and a copper wire 3. The heated end surface of the housing 1 has oblique holes and The straight holes at the center line are connected to each other for constantan wire 2 to pass through; the coaxial calorimeter shell 1 is made of oxygen-free copper material with high thermal conductivity, and the constantan wire 2 with an insulating layer is placed through the straight hole and The inclined hole is riveted on the heated end surface of the coaxial calorimeter shell 1; the copper wire 3 is riveted on the oxygen-free copper shell as a thermocouple lead to form a copper-constantan temperature measurement node, and the temperature data of the shell is obtained through a high-speed measurement and acquisition system. Combined with the relevant formulas of heat transfer, the heat flux value of the coaxia...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com