Hot needle with heat concentrated at needle point part, and manufacturing method of hot needle

A technology of heat concentration and production method, applied in the directions of needle, acupuncture, knitting, etc., can solve the problem of not reaching the treatment temperature, and achieve the effect of improving the utilization rate, small input amount, and simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

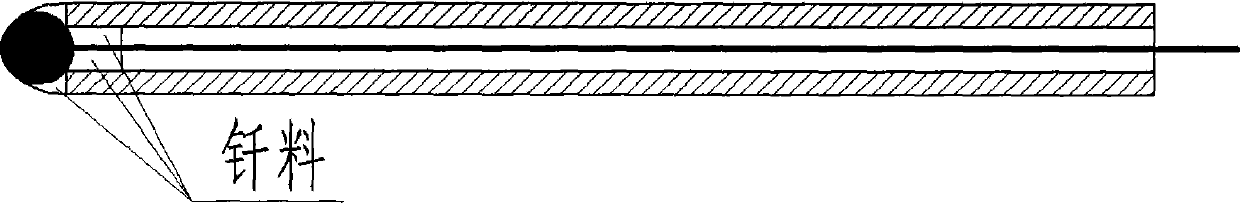

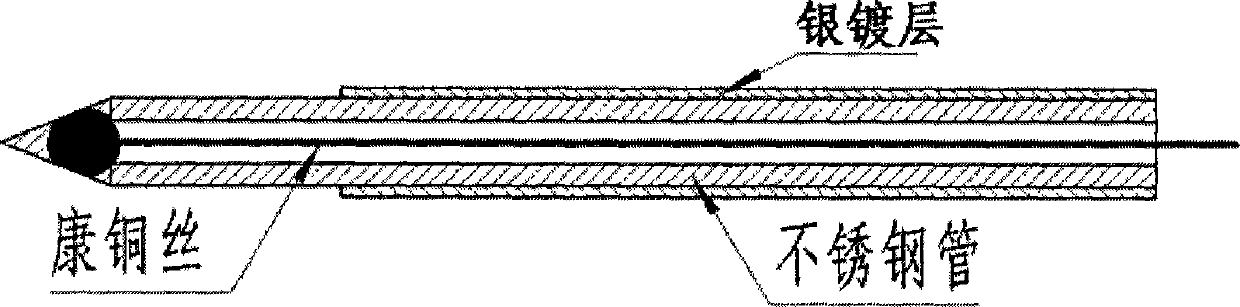

[0027] A thermal needle whose heat is concentrated at the tip of the needle. The thermal needle is a stainless steel tube thermal needle. A copper ball is welded inside the sharp end of the thermal needle. The copper ball is connected to the copper wire, and the copper wire passes inside the stainless steel tube and does not touch the inner wall. Contact, the outer wall of the hot needle 3-10mm away from the sharp end of the hot needle is plated with 1-2μm silver plating, the tail of the stainless steel tube hot needle and the copper wire are respectively connected to the two poles of the power supply, when the current passes, the part that is not plated with silver near the needle tip The resistance is large, and the heat generated is large, so that the input energy is converted into heat and concentrated near the needle tip.

Embodiment 2

[0029] (1) Use energy storage spot welding equipment to melt a small ball with a diameter larger than the stainless steel tube hot needle at the tip of the peeled copper wire. The outer diameter of the stainless steel tube hot needle is 0.4mm, the inner diameter is 0.2mm, and the copper wire The diameter is 0.09mm constantan wire.

[0030] (2) Insert the hot needle of the stainless steel tube into the crucible with liquid BAg72Cu brazing filler metal (melting point 779°C), turn on the high-frequency heater to heat it to 850-900°C in the protective atmosphere of argon, and pass the " "Push and pull" to wet the copper wire and the inner wall of the tube, and keep it for 3-5 seconds to realize the connection between the hot needle of the stainless steel tube and the copper wire. The copper wire passes through the inside of the stainless steel tube and does not contact the inner wall. The flux is FB101.

[0031] (3) Process the welded end to form a conical sharp angle, and the sur...

Embodiment 3

[0034] (1) Use energy storage spot welding equipment to melt a small ball with a diameter larger than the stainless steel tube hot needle at the tip of the peeled copper wire. The outer diameter of the stainless steel tube hot needle is 0.4mm, the inner diameter is 0.2mm, and the copper wire The diameter is 0.09mm constantan wire.

[0035] (2) Insert the hot needle of the stainless steel tube into the crucible with liquid BAg72Cu brazing filler metal (melting point 779°C), turn on the high-frequency heater to heat it to 850-900°C in the protective atmosphere of argon, and pass the " "Push and pull" to wet the copper wire and the inner wall of the tube, and keep for 3-5 seconds to realize the connection between the hot needle of the stainless steel tube and the copper wire. The copper wire passes through the inside of the stainless steel tube and does not contact the inner wall. The flux is FB102.

[0036] (3) Process the welded end to form a conical sharp angle, and the surfac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com