Heating system temperature differential measuring apparatus

A heating system and measuring instrument technology, which is applied in the direction of measuring devices, measuring heat, instruments, etc., can solve the problems of aging phenomenon, dispersion of thermoelectric characteristics of film materials, inconvenient installation of copper resistance and platinum resistance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

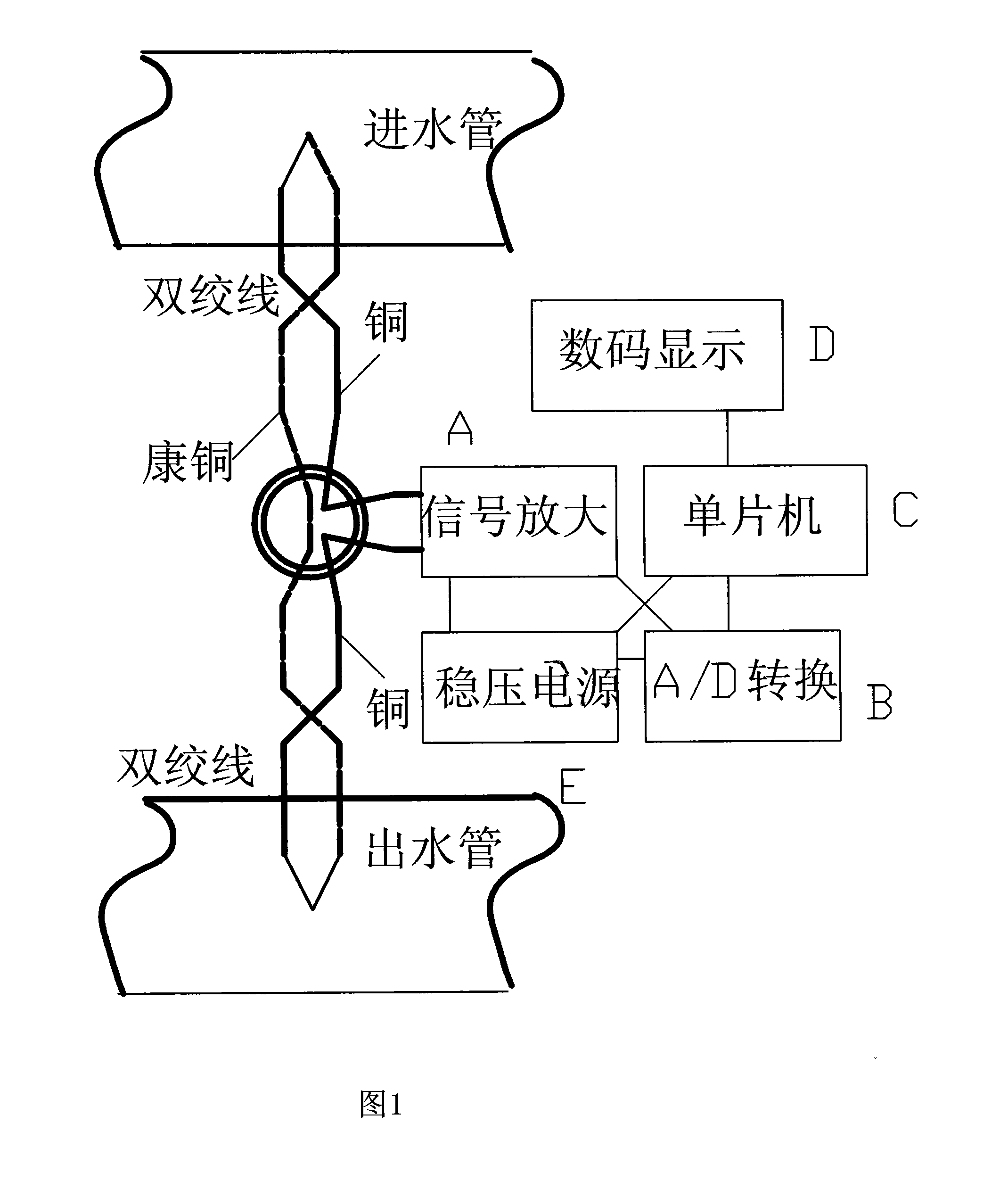

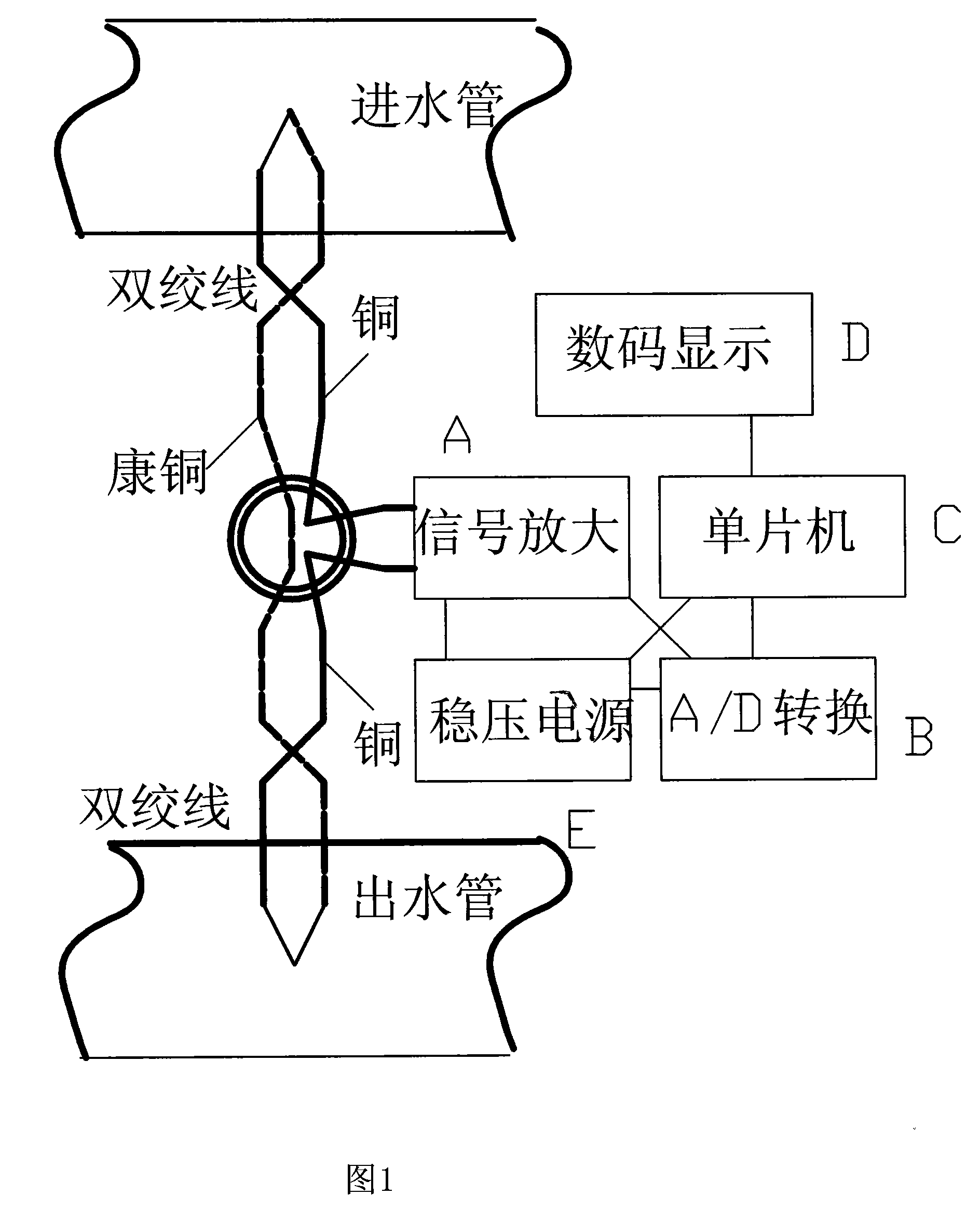

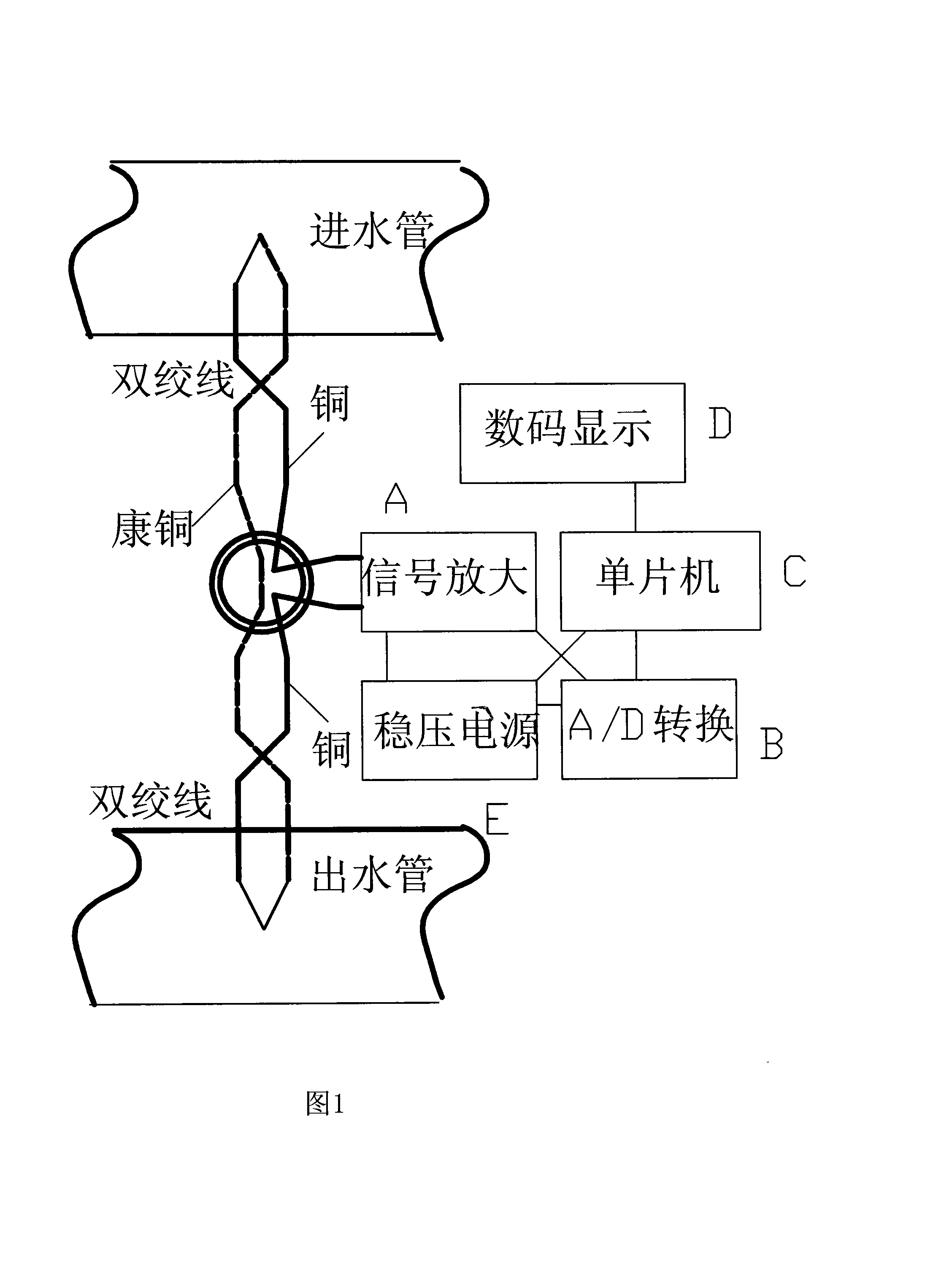

[0013] Further illustrate the present invention in conjunction with accompanying drawing and embodiment, as shown in Figure 1, the present invention is made of double-headed thermocouple and signal conditioning circuit, owing to adopting a double-headed thermocouple to replace two thermocouples usually used for measuring temperature difference, In this way, the error caused by the possible slight difference in the thermoelectric characteristics of the two thermocouples is avoided, and it is difficult to guarantee the matching accuracy of 0.1° C. with two thermocouples. Compared with the thermal resistance heating temperature difference sensor currently on the market, the difference is as follows:

[0014] (1) Compared with the thermal resistance, the measuring end of the thermocouple is very small in size, as long as the welding point of the measuring end is heated to the temperature of the medium, so the response is sensitive. Since the node is small, the heat transfer of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com