Low-temperature resistance temperature coefficient tester

A technology of temperature coefficient of resistance and temperature measurement, applied in the direction of material resistance, etc., can solve the problem of inability to measure different constant temperature media

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

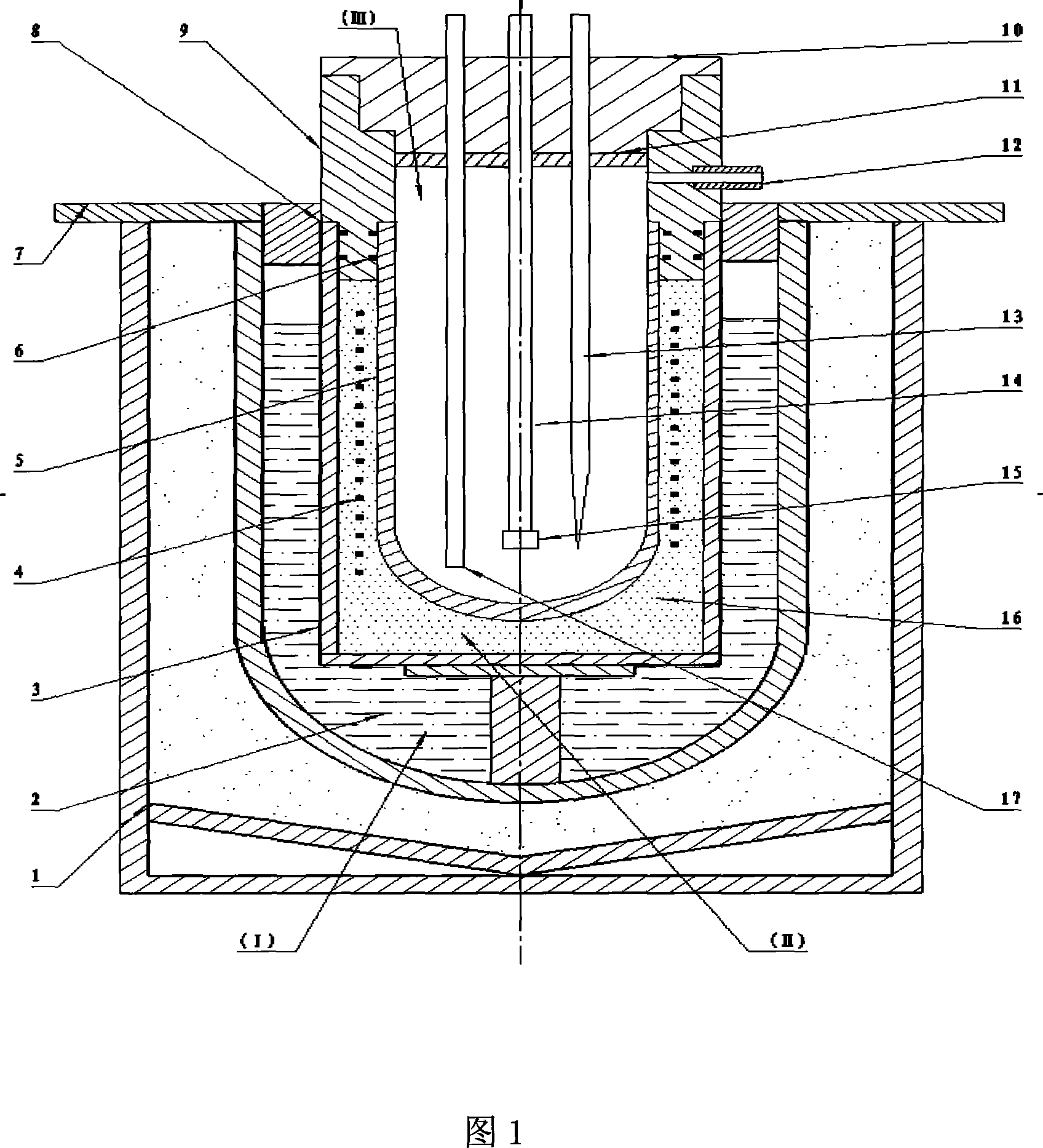

[0011] Put a certain amount of liquid nitrogen in the Dewar bottle, put the stainless steel cylinder (3) into the Dewar bottle (1), and install the heat insulating ring (8); the alloy wire material of the resistance to be measured is welded on the sample by the four-terminal method On the frame (14), the sample holder (14), PT thermal resistance (17), copper-constantan thermocouple (13) (PT thermal resistance can also be used) are inserted in the quartz tube, and the gland (10) is tightened. The PT thermal resistance (17) cooperates with the SWP-N intelligent digital instrument to control the temperature in the quartz tube to a specific temperature, connect the power supply of the SWP-N intelligent digital instrument, set the measurement temperature on the SWP-N intelligent digital instrument, and use copper-constantan Thermocouple (13) (PT thermal resistance can also be used) to measure the actual temperature in the quartz tube (5), and after the actual temperature is stabiliz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com