Aluminum powder mixing and metering device

A metering device and aluminum powder technology, applied in the direction of selling raw material supply devices, etc., can solve problems such as troublesome operation, waste of manpower and material resources, and difficulty in realizing automatic metering and automatic addition, so as to achieve the effect of convenient operation and avoiding mistakes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

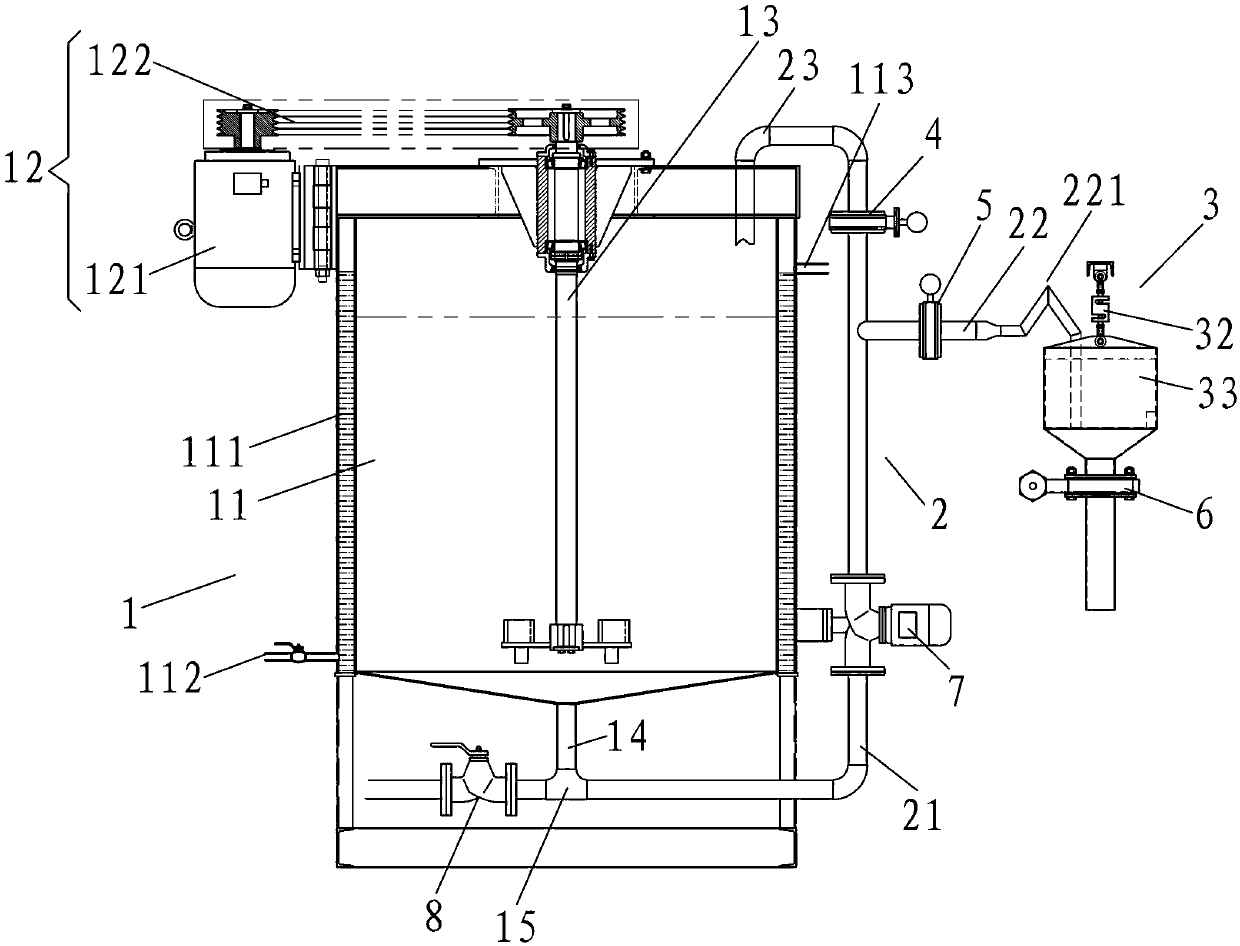

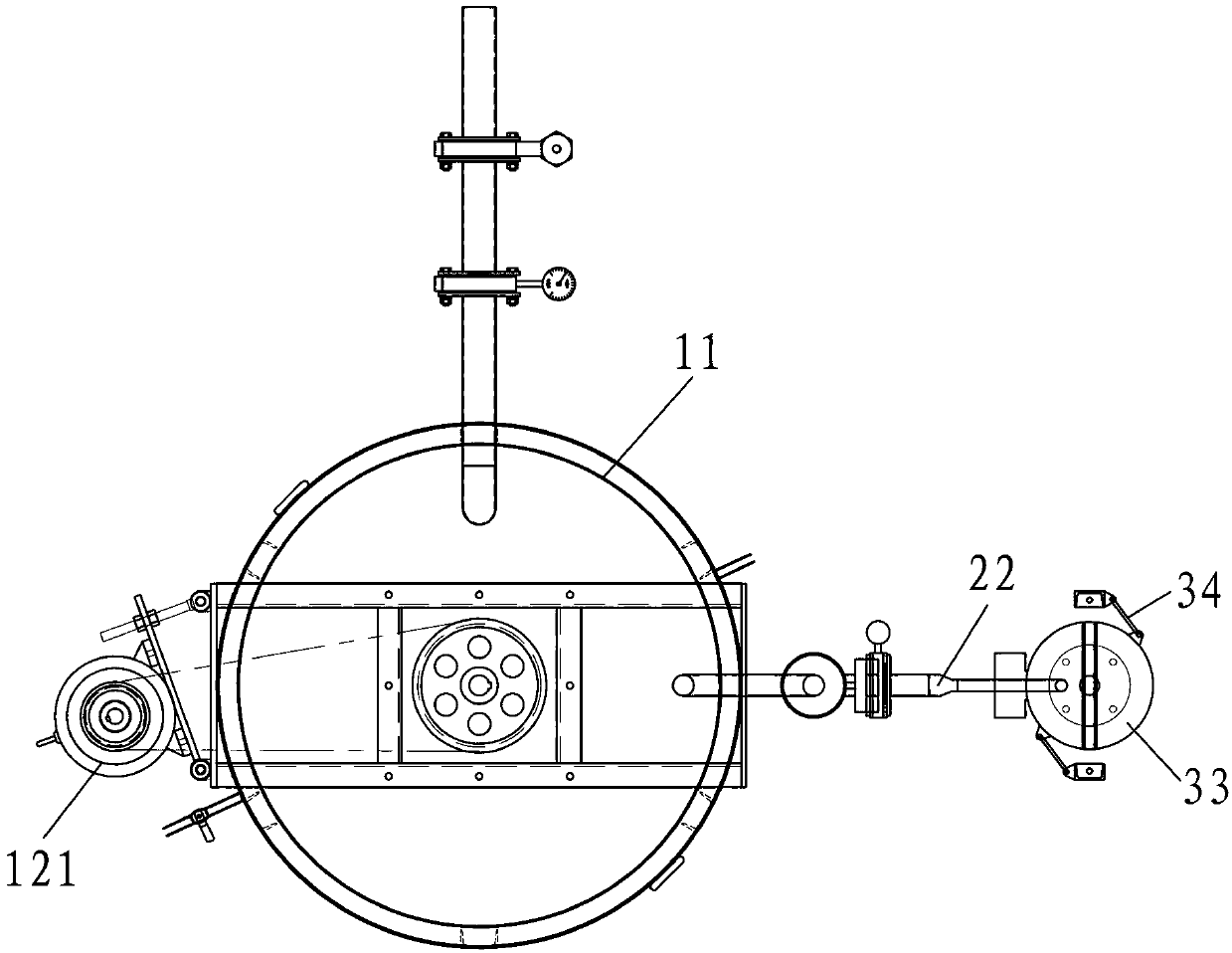

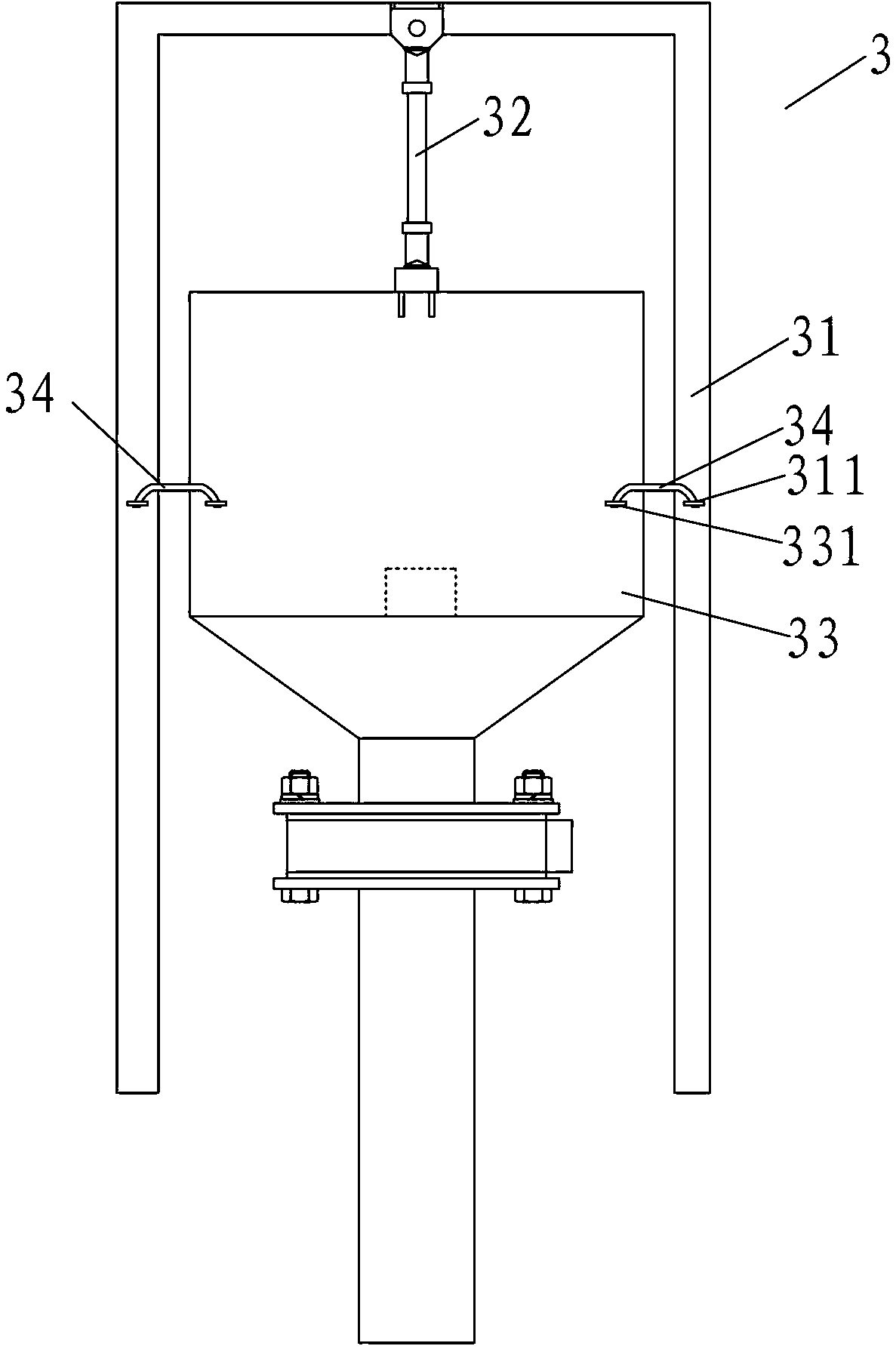

[0024] The aluminum powder stirring and metering device of the present invention, such as figure 1 , 2 , 3, including mixing system 1, pipeline system 2, metering system 3, circulation control valve 4, metering feed control valve 5, metering discharge control valve 6, pipeline circulation pump 7 and blowdown valve 8.

[0025] The stirring system 1 includes a stirring drum 11 , a driving part 12 and a stirring member 13 .

[0026] The wall of the mixing cylinder 11 has an interlayer 111 for accommodating cooling water. The interlayer 111 has a cold water inlet 112 and a water outlet 113. The cold water inlet 112 is connected to the water source through a water inlet pipe and a water inlet valve, and the water outlet 113 is outward through a pipe. The aluminum slurry (a mixture of aluminum powder and water stirred) in the mixing cylinder 11 is cooled by the circulating cooling water in the interlayer 111 to keep the temperature of the aluminum slurry from rising and ensure prod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com