Method and apparatus of measuring large-sized vertical shaft throw

A vertical shaft, large-scale technology, applied in the field of measurement, can solve problems such as high cost, large measurement error, and stopping at a specified position

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

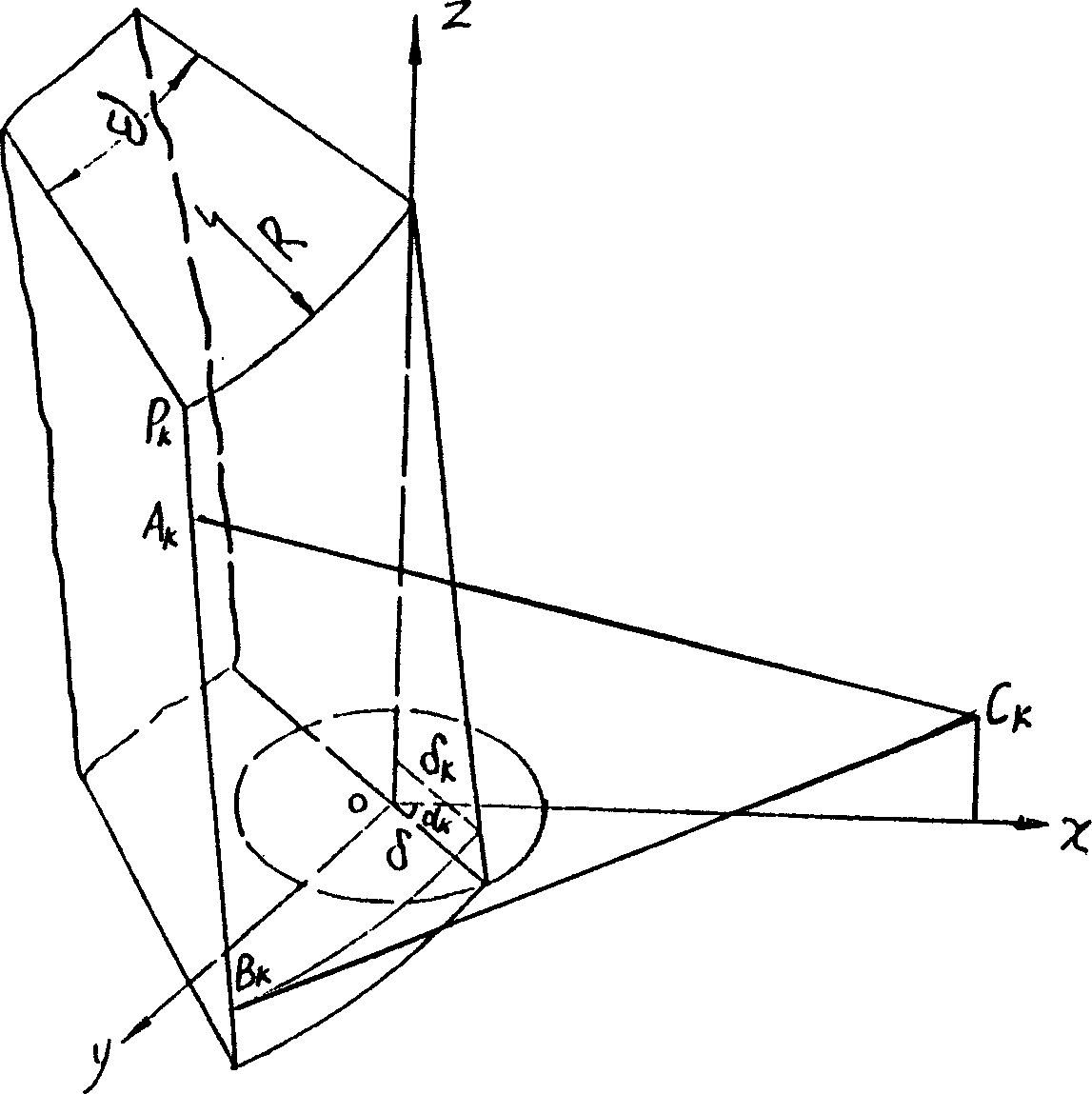

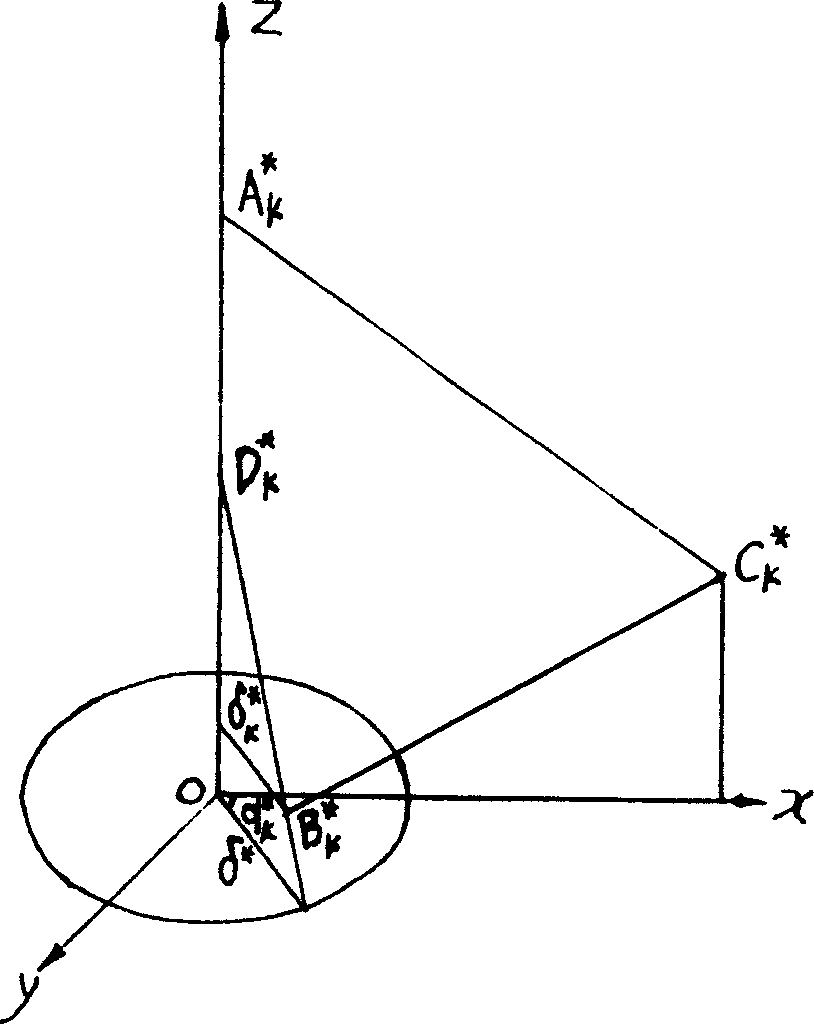

[0059] The specific implementation, structure, features and effects provided by the present invention will be described in detail below in conjunction with the accompanying drawings and preferred embodiments.

[0060] 1. Preparations before measurement of vertical axis swing and combined vertical axis relative swing:

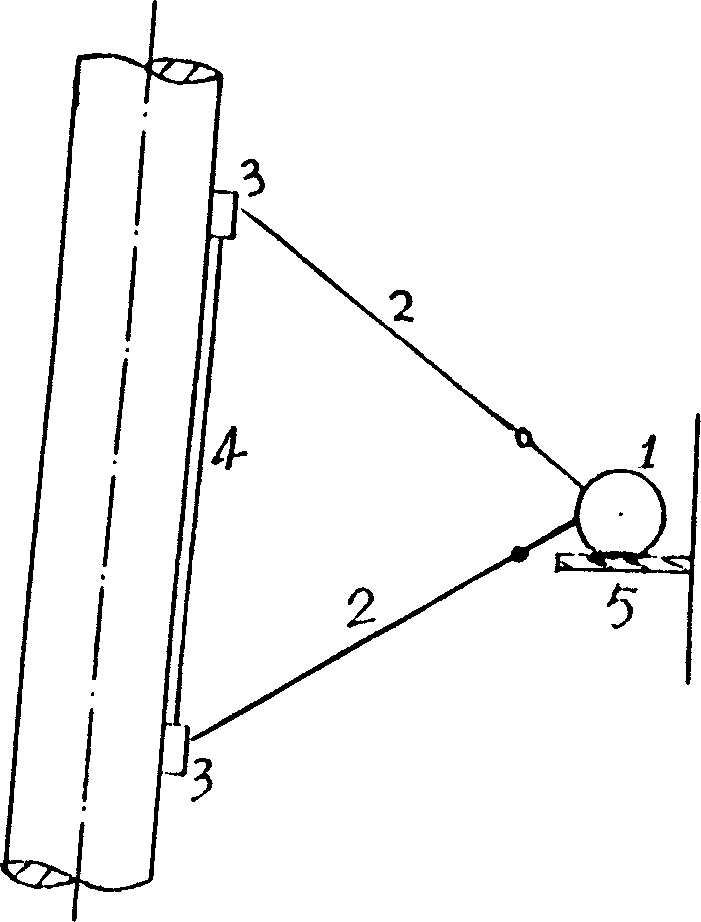

[0061] Tool and instrument preparation: such as figure 1 , an improved dial gauge 1, slightly changing the shape and structure so that the dial gauge can slide freely on the measuring block (without rotation), the internal structure also needs to be changed, and the linear-circular motion of the conventional dial gauge is cancelled. The conversion mechanism is replaced by a winding wheel (connected with the reading gear device by the rotating shaft). The dial indicator has two shorter lead-out lines, and each thread has a wire buckle. The outer dimension of the wire buckle is larger than the size of the outlet. Two different winding methods are respectively ap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com