Radial strain measurement device for compression test at high temperature and high pressure

A high temperature and high pressure, measuring device technology, used in measuring devices, using stable tension/pressure to test the strength of materials, instruments, etc., can solve the problems of high equipment price, cumbersome links, troublesome leads, etc., to achieve reliable performance and easy to use. , Easy to use and reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

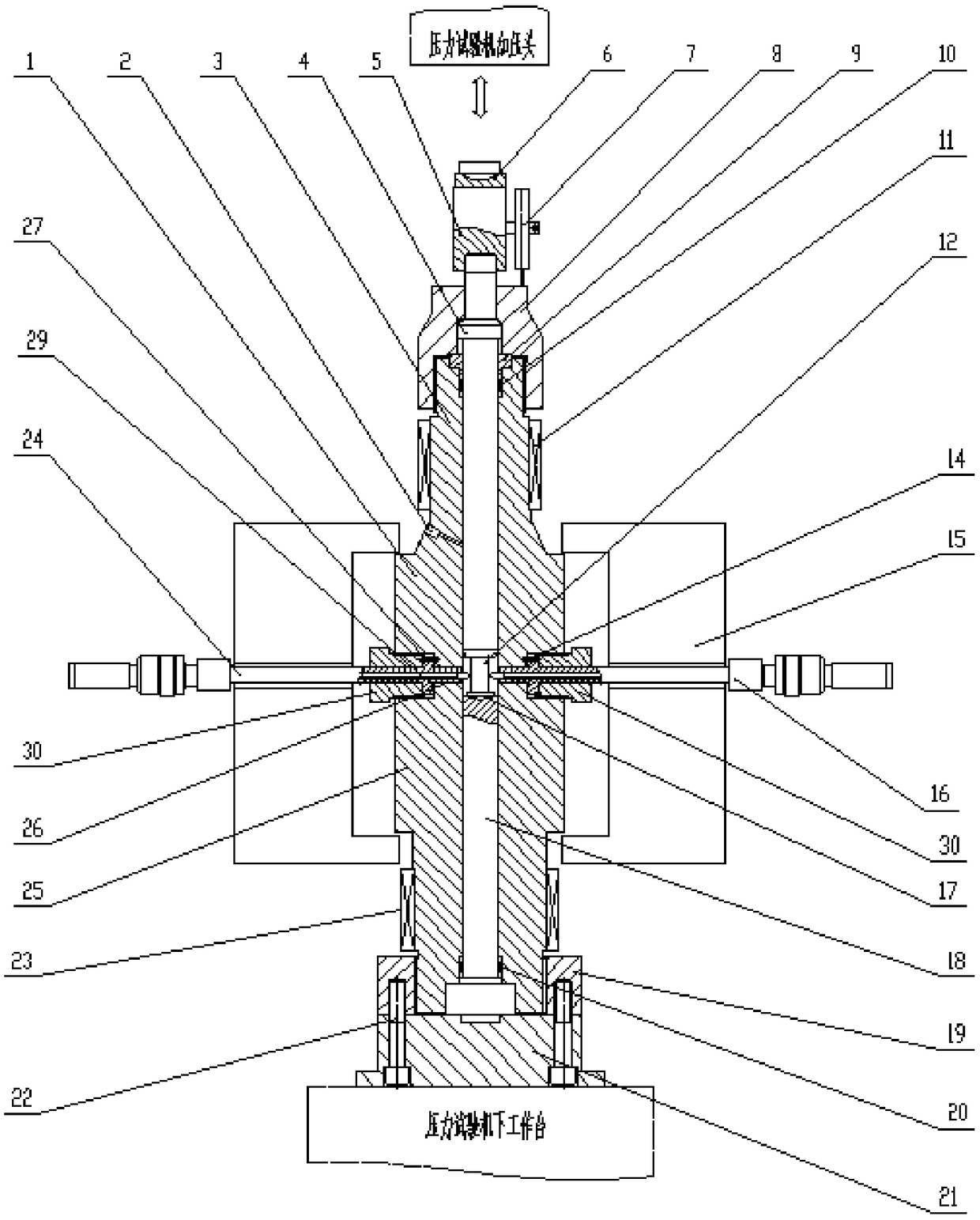

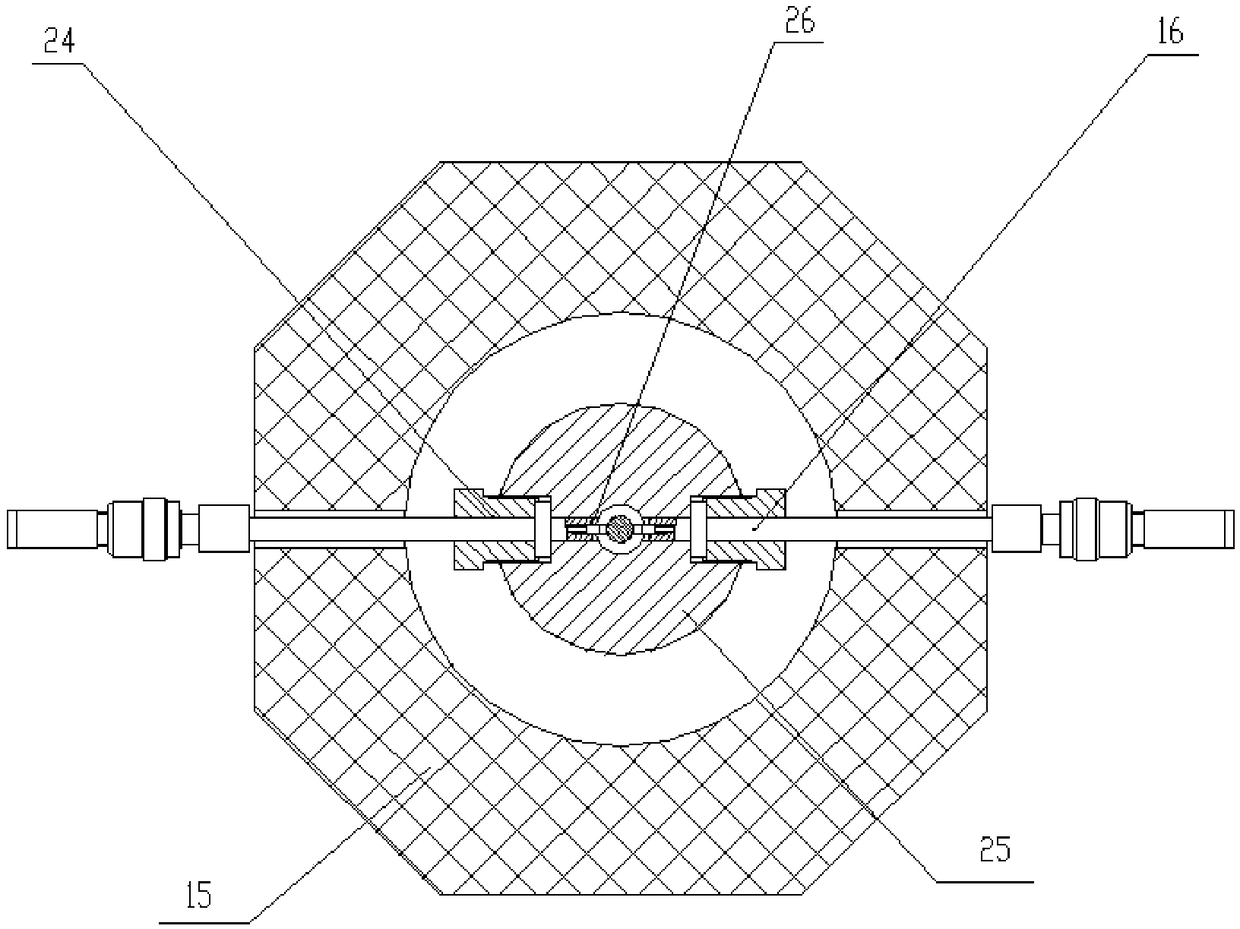

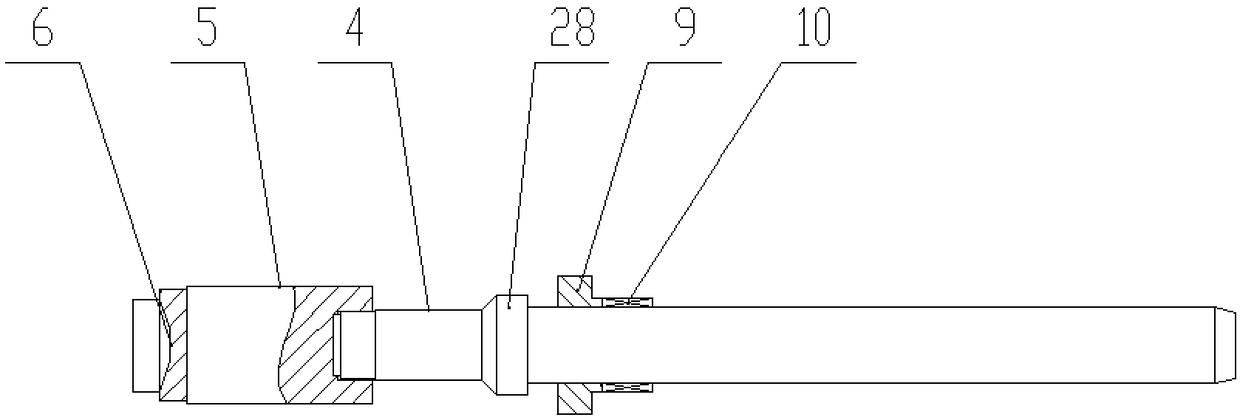

[0031] Embodiment 1: as attached Figures 1 to 5 As shown, a radial strain measuring device for compression test under high temperature and high pressure, it includes a kettle body 1 and a heating furnace 15, the kettle body 1 is a cylindrical hollow cylinder structure, and the middle part of the kettle body 1 is provided with a heating section convex ring 25 The convex ring 25 of the heating section is located in the center of the hearth of the two-half open and close heating furnace 15, a pressure device is provided at the upper end of the kettle body 1, a supporting device is provided at the lower end of the kettle body 1, and a horizontal direction is provided in the middle of the kettle body 1. There is a radial measuring device, a sample 12 is arranged in the middle of the cavity of the kettle body 1, the measuring head of the radial measuring device is in contact with the side wall of the sample 12, and the side wall of the kettle body 1 above the convex ring 25 of the h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com