Scraping device for polyimide constantan foil electric heater

A copper foil electric heater, polyimide Kang technology, which is applied in the direction of the device for coating liquid on the surface, coating and other directions, can solve the problems of uncontrollable glue liquid thickness, uneven glue liquid, low production efficiency, etc., To achieve the effect of simple structure, uniform glue and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

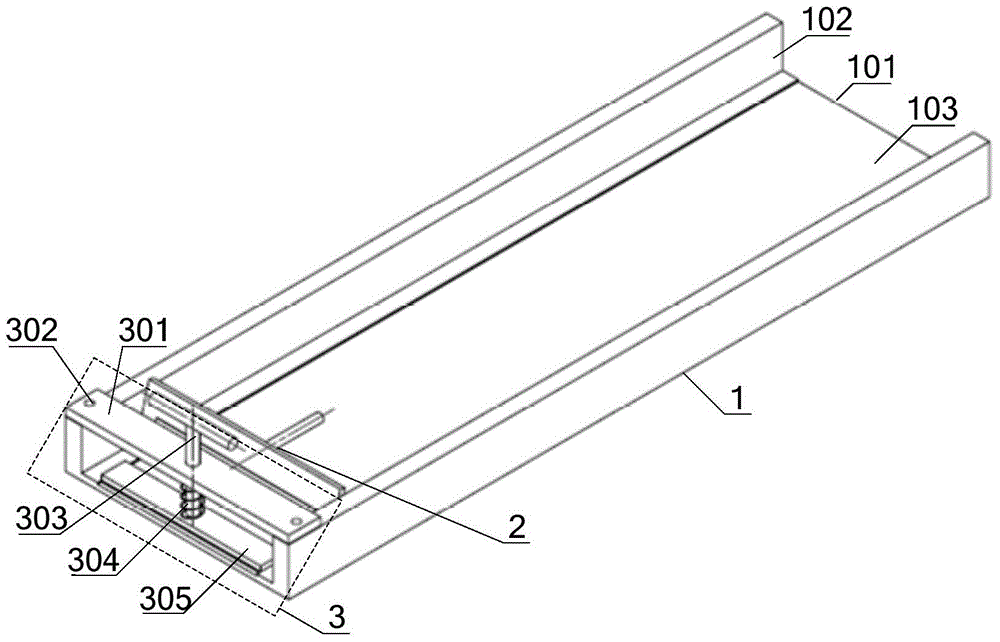

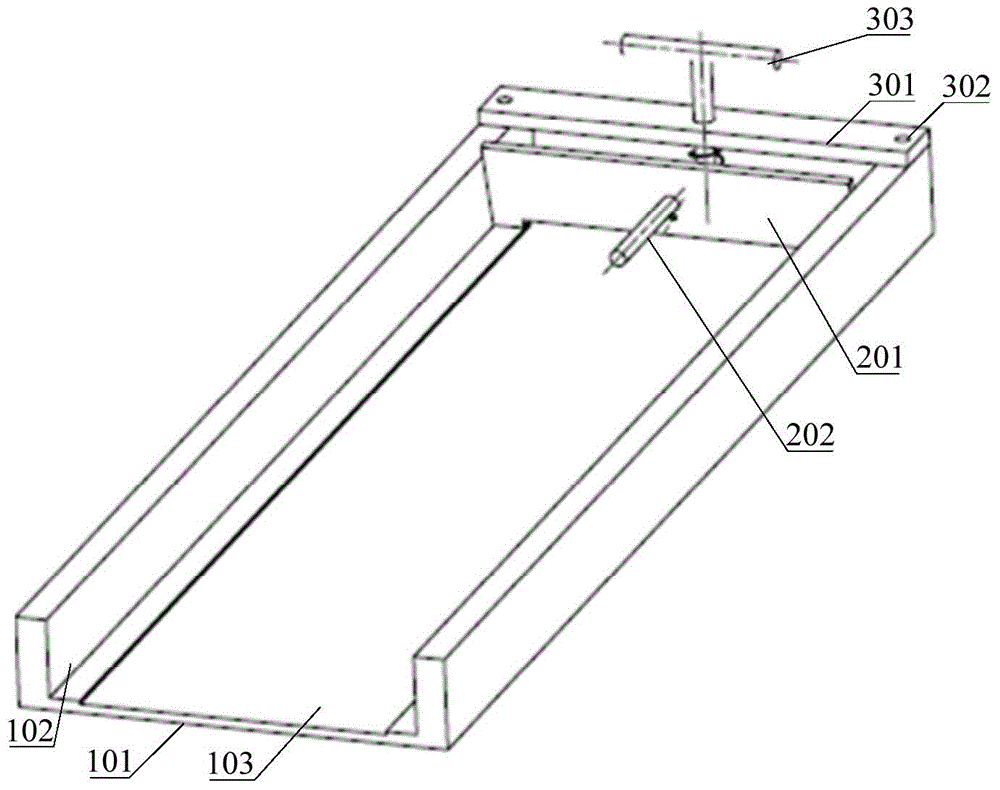

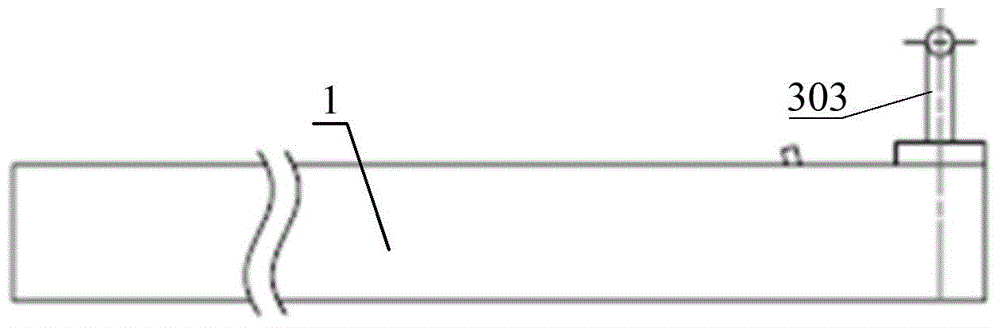

[0018] See attached figure 1 , attached figure 2 , attached image 3 , attached Figure 4 And attached Figure 5 , a polyimide constantan foil electric heater squeegee device of the present invention comprises a bottom platform 1, a pressing device 3 and a squeegee structure 2;

[0019] The bottom platform 1 is a U-shaped integrated structure, including a bottom plate 101, side walls 102 are arranged on both sides of the bottom plate 101 in the length direction, and the bottom plate 101 is a groove structure with a groove 103 in the middle;

[0020] The pressing device 3 is fixed at one end of the base 1 to fix the heating sheet, and the squeegee structure 2 slides along the side wall 102 of the base 1 to squeegee.

[0021] Described pressing device 3 comprises fixing strip 301, pull rod 303, fixing pressing plate 305 and fixing spring 304; A fixe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com