High-current, waterproof and high-temperature resisting cable connector

A cable connector and connector technology, used in waterproof, high temperature resistant cable connectors, and high current fields, can solve problems such as restricting the use range and use effect of cable connectors, delaying equipment replacement time, and failing to achieve use effects. , to achieve the effect of saving equipment replacement time, reducing labor intensity and improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

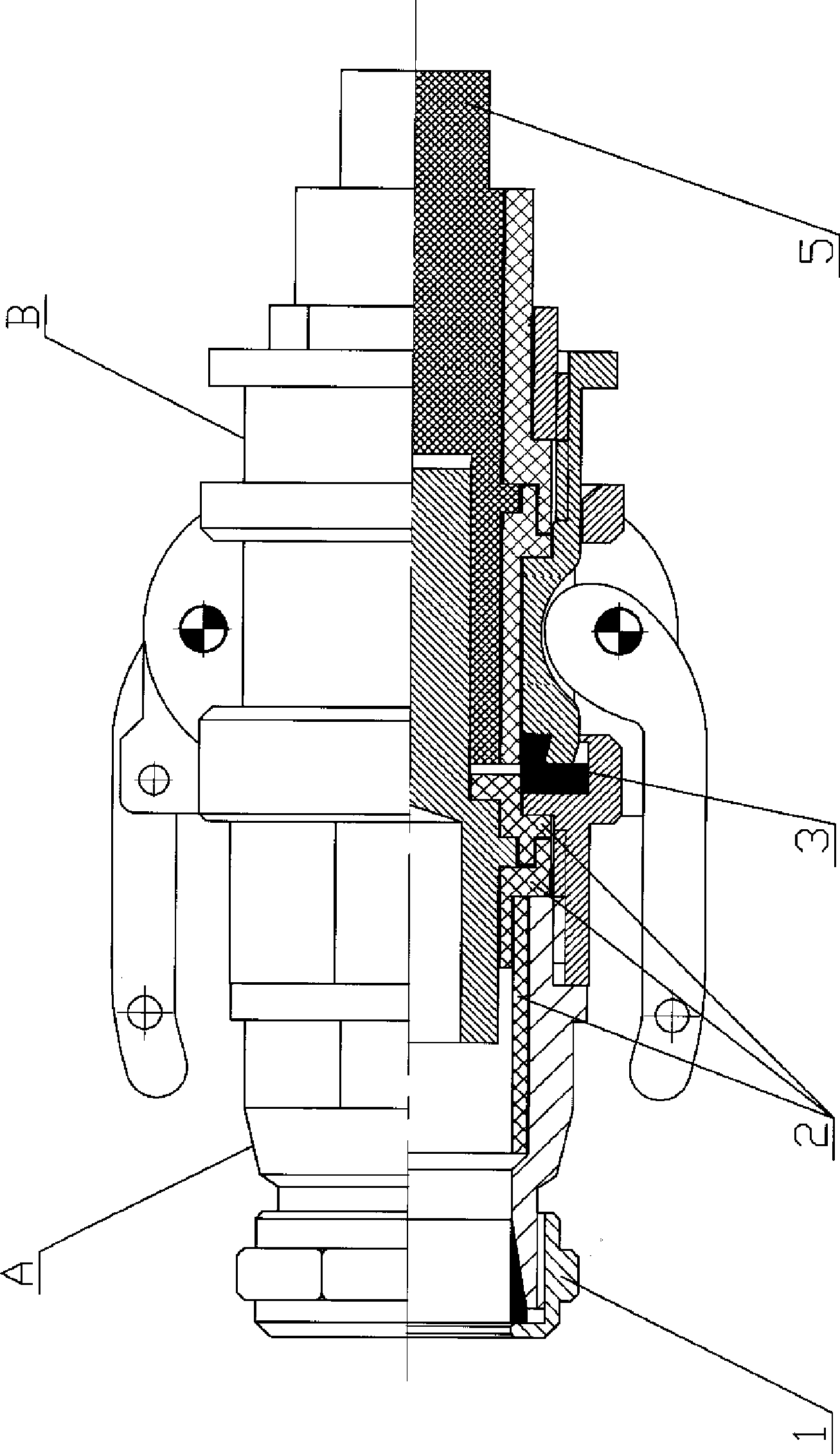

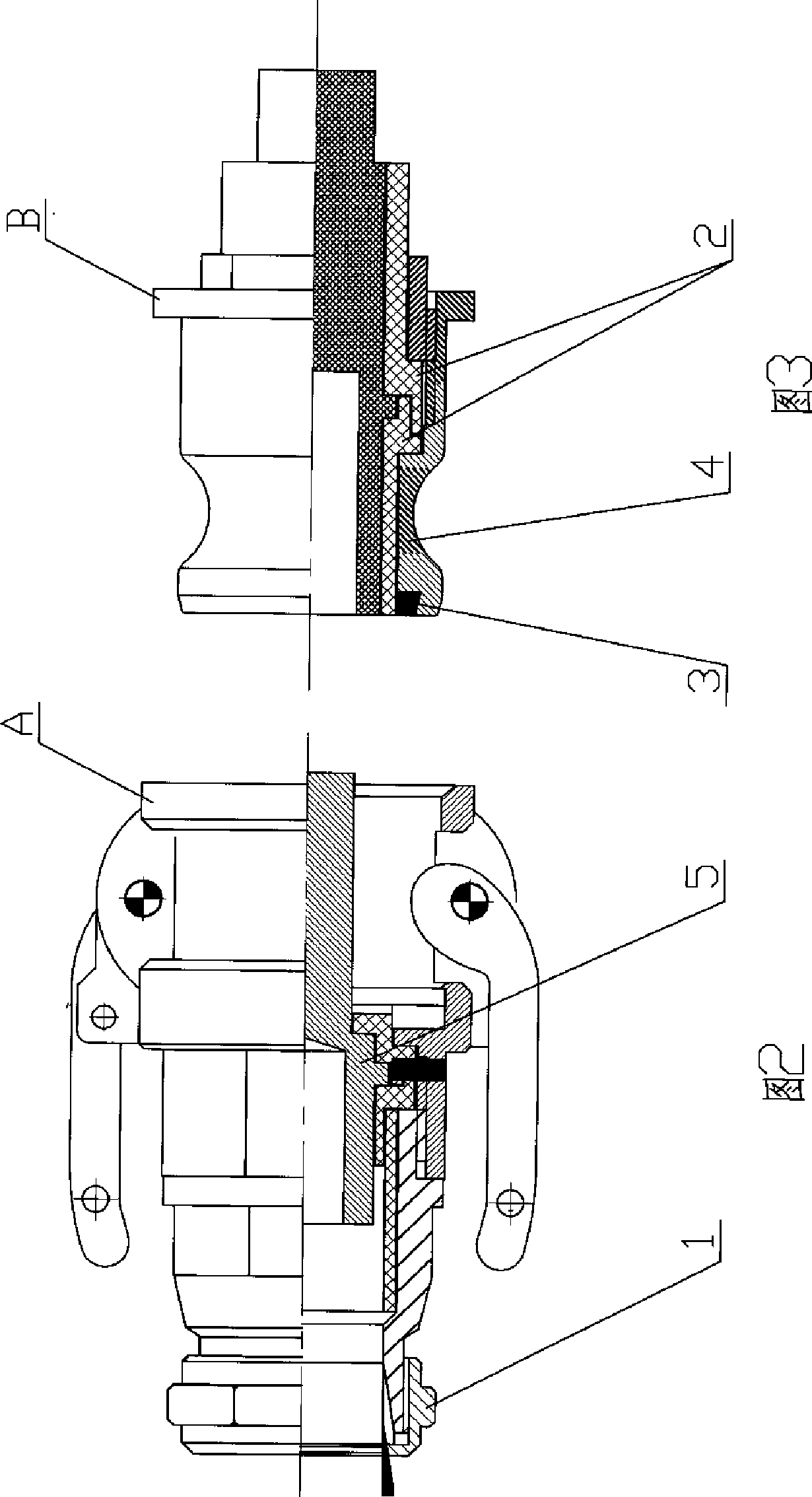

[0014] Depend on Figures 1 to 3 It can be seen that the present invention includes:

[0015] The connector consists of two parts, A and B, where part A and part B are socketed together for quick connectors;

[0016] The A part is a connection sleeve, one end of the connection sleeve is a cavity for fixing and sealing the cable, and the other end is the electrode core 5 connected to the B part;

[0017] The B part is a movable sleeve connected to the electrode core 5, one end of the movable sleeve is inserted into the connector A part, and is socketed with the electrode core 5 of the connector A part, and the other end is a fixed embedded end of the electrode core 5.

[0018] Part A of the connector according to the present invention includes a waterproof plug sleeve 1, an insulating inner sleeve 2 and a seal 3, wherein the waterproof plug sleeve 1 is arranged at the end of the connector to fix and seal the cable, and the insulating inner sleeve 2 is arranged on the wall of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com