Electric heating piece, electric heating device and equipment

A heating element and heating element technology, applied in electric heating devices, ohmic resistance heating, electrical components, etc., can solve the problems of limited application range of electric heating elements, low heating element power, and low heat transfer efficiency. The effect of increased thermal velocity, improved heat transfer efficiency, and increased application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

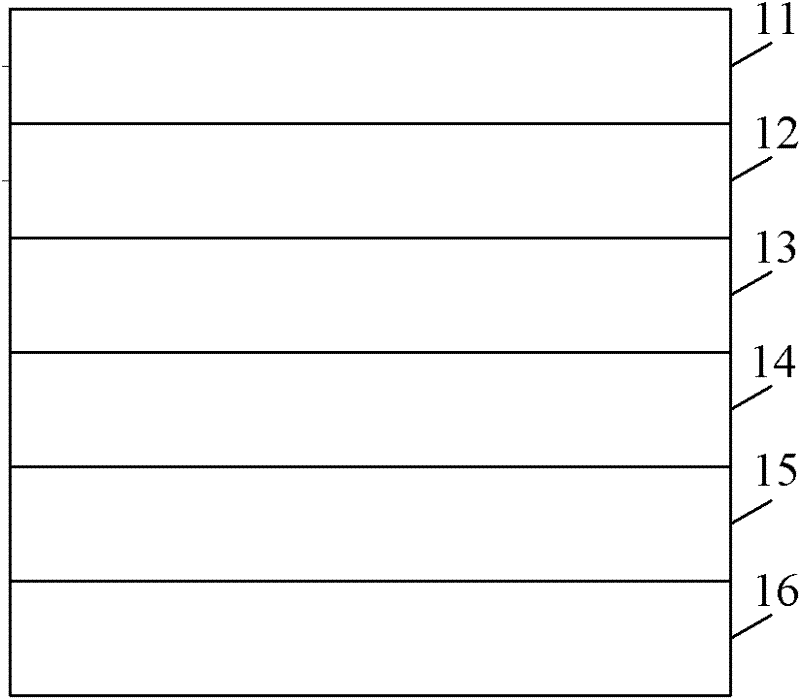

[0018] Figure 1-A The structure of the first electric heating sheet material layer provided by the embodiment of the present invention is shown, and for the convenience of description, only the parts related to the embodiment of the present invention are shown.

[0019] The material layer of the electric heater includes:

[0020] The first insulating layer 11 is used for insulating and protecting the constantan foil;

[0021] The heating layer 12 made of constantan foil, the first surface is connected to the first insulating layer 11, and is used to generate heat after electrification;

[0022] The second insulating layer 13, the first surface of which is connected to the second surface of the heating layer 12, is used for insulating and protecting the constantan foil;

[0023] The first adhesive layer 14, the first surface of which is connected to the second surface of the second insulating layer 13, is used to bond the heat equalizing layer 15 and the second insulating lay...

Embodiment 2

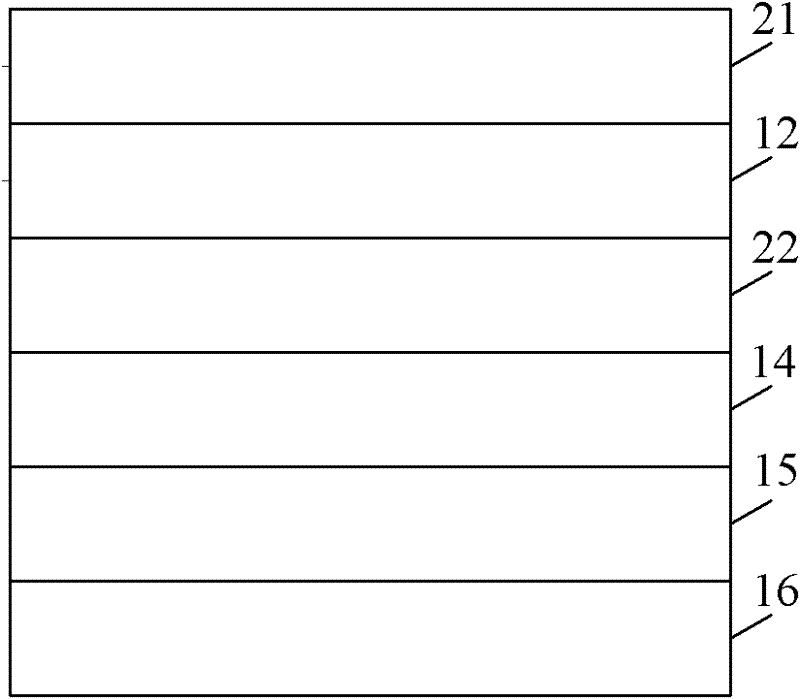

[0029] figure 2 The structure of the material layer of the second heating sheet provided by the embodiment of the present invention is shown, and only the parts related to the embodiment of the present invention are shown for convenience of description.

[0030] In this embodiment, the first insulating layer and / or the second insulating layer adopts a polyimide film, and the polyimide film is thinner and lighter than the traditional electric heater insulating layer, so when polyimide When the film is used as an insulating layer and constantan foil as a heating layer, the thickness and weight of the heating element can be reduced more effectively, so that the heating element can meet the requirements of defense electronic products, aerospace equipment, portable medical instruments, high-density electronic equipment, etc. Heating requirements for applications that require more sophisticated instruments or equipment.

[0031] In addition, the polyimide film can better protect t...

Embodiment 3

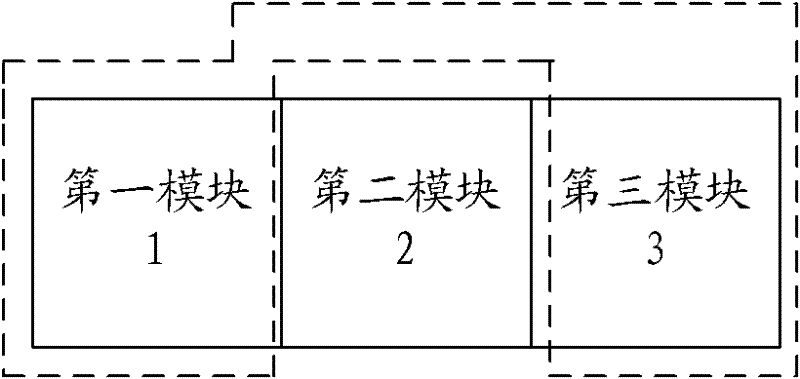

[0034] Figure 4 A structural diagram of the electric heater provided by the embodiment of the present invention is shown, and only parts related to the embodiment of the present invention are shown for convenience of description.

[0035] The electric heating sheet is composed of a heating sheet 41 and a conductive wire 43 , and the joint of the conductive wire 43 and the heating sheet 41 is pressed together by a high temperature resistant glue 42 . By adopting this method, no space is left around the conductive wire, so as to better protect the conductive wire from being disconnected.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com