Preparation method of graphene field-effect transistor biosensor

A technology of field-effect transistors and biosensors, applied in the field of preparation of graphene field-effect transistor biosensors, can solve the problems of affecting the electrical properties of probe-modified graphene, long time, usually more than 2 hours, and expensive preparation equipment. Achieve the effect of retaining superior performance, short copper etching time, and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

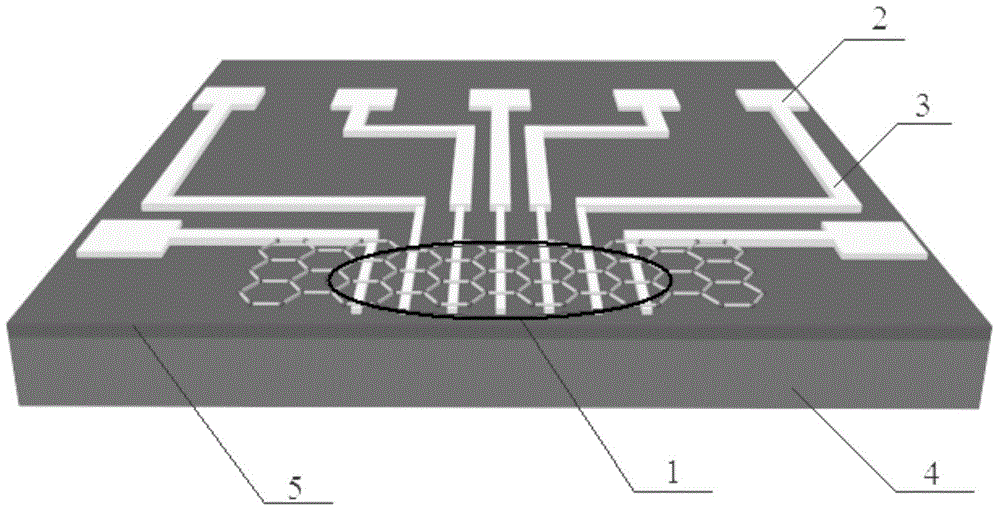

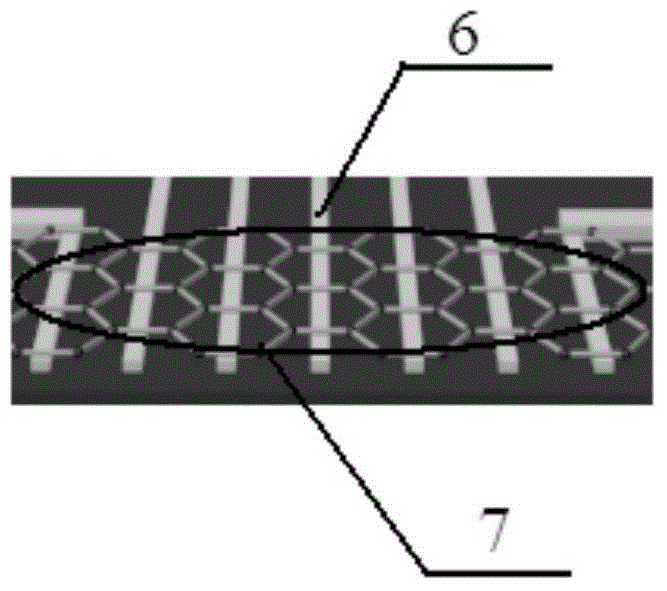

[0029] refer to figure 1 and figure 2 Shown, the structure of graphene field effect transistor biosensor: comprise base layer, described base layer is made of silicon substrate (6) and the silicon dioxide (7) that is deposited on the silicon substrate, is provided with sensing array on the base layer (1), electric pad (2) and wire (3), described sensing array comprises 7 parallel metal electrodes (4), and every two metal electrodes that are adjacent in sequence are combined to form a group of metal electrode pairs, altogether 6 groups of metal electrode pairs are formed, a graphene conductive channel (5) is formed by covering graphene between two metal electrodes of each group of metal electrode pairs, and each of the 7 metal electrodes is connected to an electric pad through a wire. connected, the electric pad is connected with the external signal detection device.

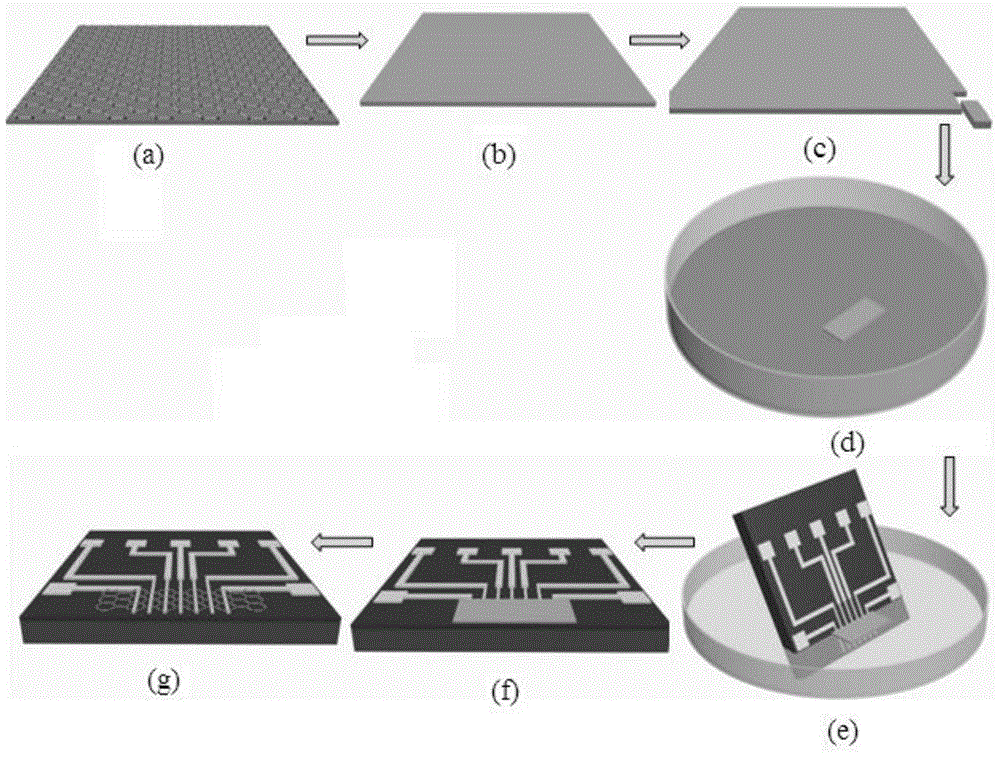

[0030] The preparation method of above-mentioned graphene field effect transistor biosensor, comprises the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com