Gold-silver-rhodium multilayer composite plating process

A multi-layer composite and electroplating process technology, applied in the field of surface treatment, can solve problems affecting product reliability and airtightness, and achieve the effects of easy welding, low porosity and uniform distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

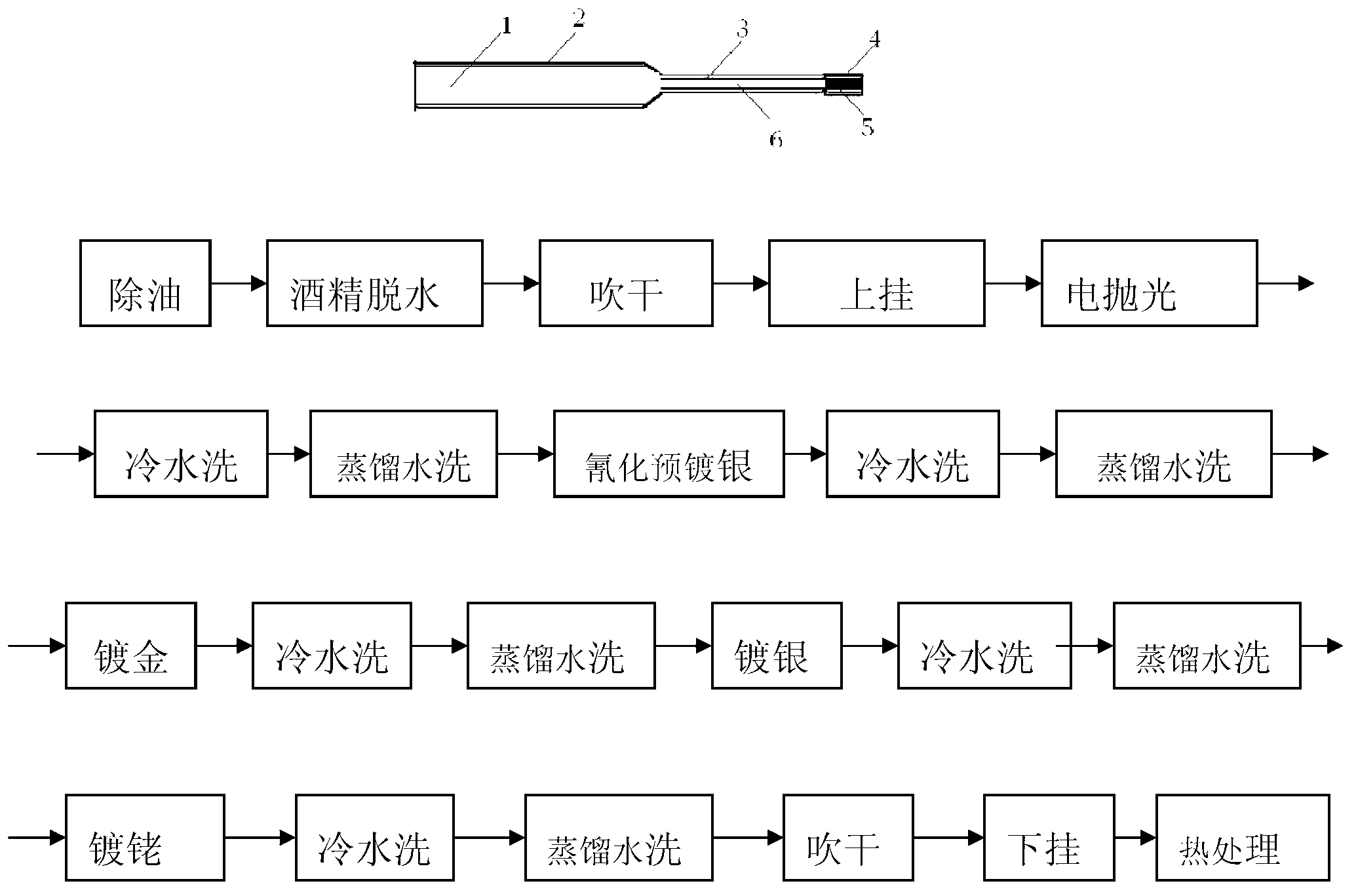

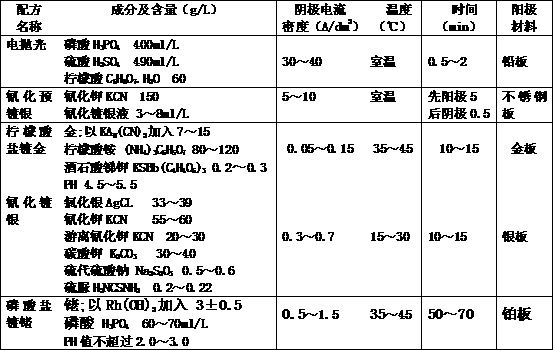

[0024] refer to figure 1 . The parts have been mechanically processed and heat treated before electroplating. First, they are cleaned with gasoline, then cleaned with metal oil cleaning agent, dehydrated with anhydrous ethanol, blown dry, and electropolished to level the roughness of the metal surface and produce luster to obtain a smooth and bright surface. surface. Design a specific electroplating rack to fully ensure that the surface power lines of the parts to be plated are evenly distributed. Hang the parts that have been degreased and cleaned and dried, and electroplate the parts according to the process flow chart.

[0025] Gold, silver and rhodium multilayer composite electroplating process, including electropolishing process, cyanide pretreatment process, citrate gold plating process, cyanide silver plating process, phosphate rhodium plating process, and then heat treatment process. The gold-silver-rhodium multilayer composite electroplating process comprises the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com