Method for preparing high-purity molybdenum titanium sputtering target

A molybdenum sputtering target, high-purity technology, applied in sputtering coating, metal material coating process, ion implantation coating and other directions, can solve the problem of difficulty in preparing large-sized molybdenum sputtering target The density is not easy to control, the process and operation are complicated, etc., to achieve the effect of low cost, low equipment requirements, and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0020] A method for preparing a high-purity molybdenum sputtering target. The preparation process uses ammonium dodecamolybdate as a raw material, and high-purity molybdenum powder is prepared by two-stage hydrogen reduction, and then the high-purity molybdenum powder is cold isostatically pressed Molybdenum slab green body, then vacuum pre-sintering, and then sintering at high temperature under hydrogen atmosphere to make high-purity molybdenum slab; finally, the sintered high-purity molybdenum slab is processed into molybdenum molybdenum by forging first and then rolling. The target blank, after vacuum annealing, is then machined into a finished molybdenum sputtering target according to the specified specifications.

[0021] During operation, ammonium dodecamolybdate with regular hexagonal prism shape, uniform size and no agglomeration is used as the raw material, and the K content is controlled to be 2-5ppm, the Fe content is 3-7ppm, and the Ni content is less than or equal ...

Embodiment 1

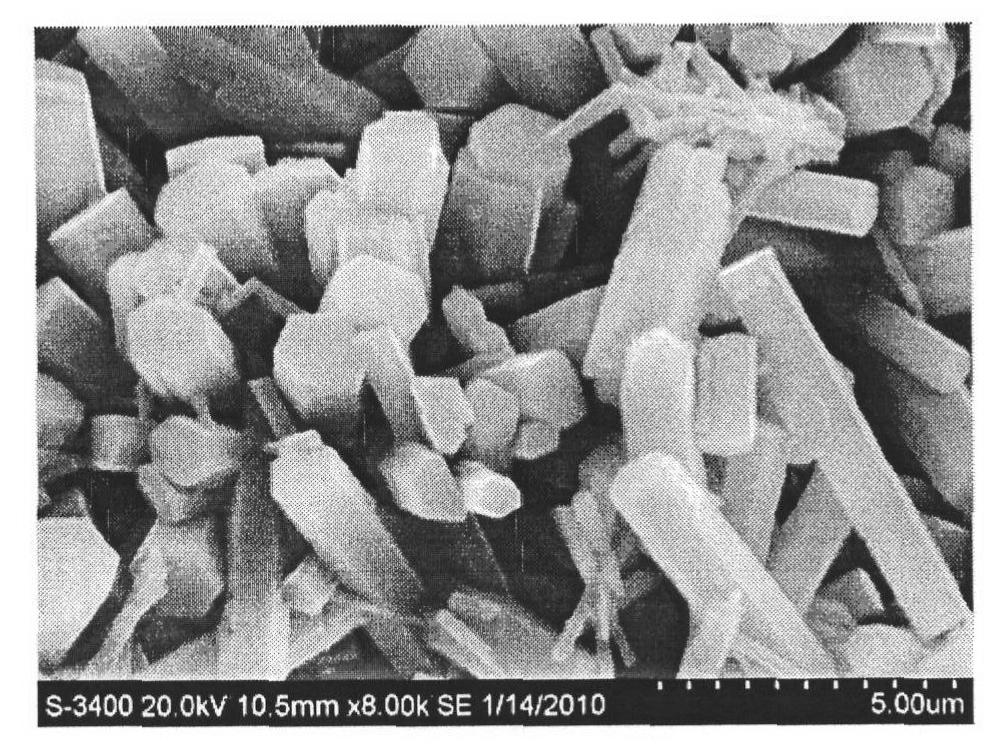

[0026] Ammonium dodecamolybdate with regular hexagonal column shape, uniform size and no agglomeration is used as raw material ( figure 1 ), the control K content is 5ppm, the Fe content is 7ppm, and the Ni content is 2ppm. It is subjected to two-stage hydrogen reduction in a hydrogen reduction furnace, and the reduction process is carried out according to the reduction process of conventional molybdenum powder. During the reduction process, molybdenum boats are used for the boats, and the inner surface of the reduction furnace tube is inlaid with molybdenum bushings. The purity of the prepared molybdenum powder is 99.99wt%.

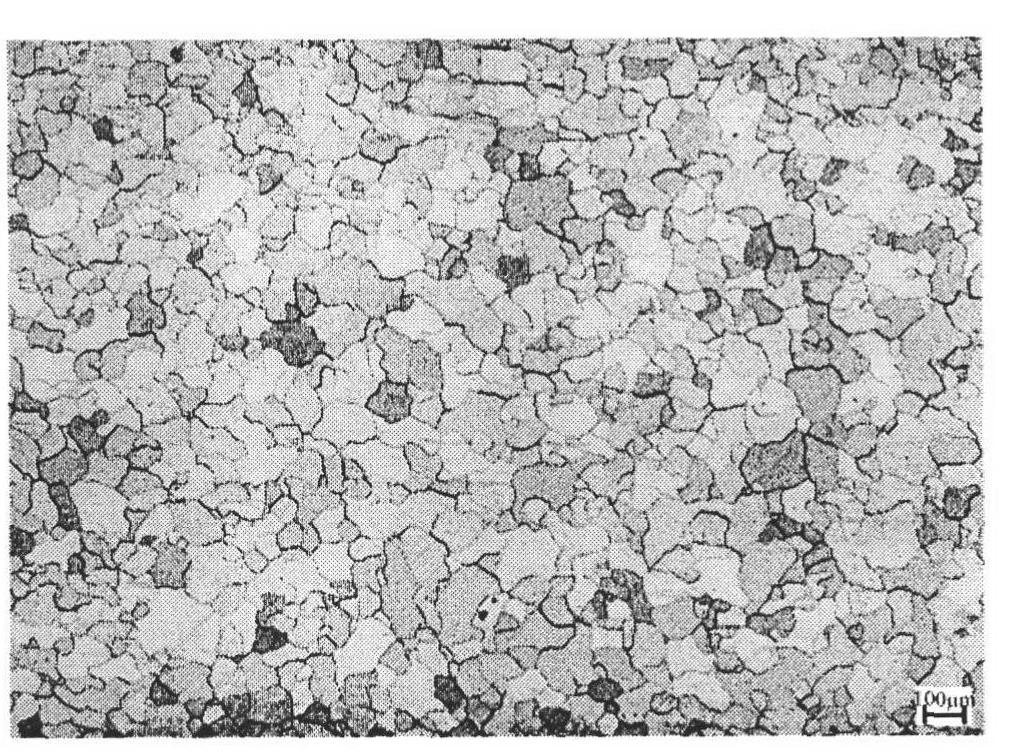

[0027] The molybdenum powder is pressed into a molybdenum plate green body by cold isostatic pressing, the pressing pressure is 180 MPa, and the holding time is 10 minutes. Then the molybdenum plate green body is vacuum pre-fired, the pre-fired temperature is 1400 ℃, and the vacuum degree is 10 -3 Pa, the holding time is 1 hour; the pre-fired molybden...

Embodiment 2

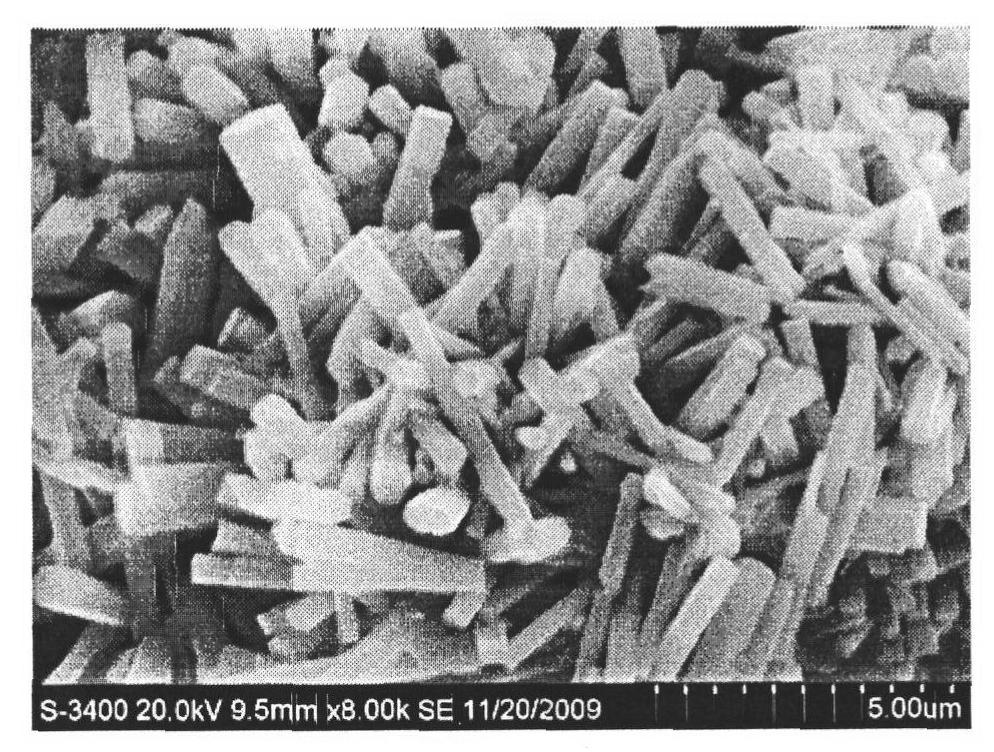

[0031] Ammonium dodecamolybdate with regular hexagonal column shape, uniform size and no agglomeration is used as raw material ( image 3 ), the control K content is 2ppm, the Fe content is 3ppm, and the Ni content is less than 1ppm. It is subjected to two-stage hydrogen reduction in a hydrogen reduction furnace, and the reduction process is carried out according to the reduction process of conventional molybdenum powder. During the reduction process, molybdenum boats are used for the boats, and the inner surface of the reduction furnace tube is inlaid with molybdenum bushings. The purity of the prepared molybdenum powder is 99.992wt%.

[0032] The molybdenum powder is pressed into a molybdenum plate green body by cold isostatic pressing, the pressing pressure is 200 MPa, and the holding time is 20 minutes. Then the molybdenum plate green body is vacuum pre-fired, the pre-fired temperature is 1200 ℃, and the vacuum degree is 10 -4 Pa, the holding time is 2 hours; the pre-fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average grain size | aaaaa | aaaaa |

| Average grain size | aaaaa | aaaaa |

| Average grain size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com