Preparation method of oxide dispersion strengthened FeCrAl alloy pipe

A technology of dispersion strengthening and oxide, which is applied in the field of preparation of oxide dispersion strengthening FeCrAl alloy pipes, can solve the problems of restricting the development of nuclear power industry and relying on imports, and achieve excellent mechanical and creep resistance properties, short processing period, excellent anti-corrosion The effect of oxidation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

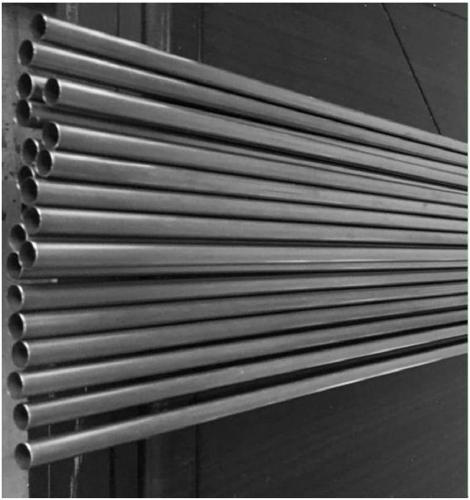

[0023] Using QX-QM20 high-energy ball mill to mechanically mill FeCrAl and Y 2 o 3 powder, and thermally consolidated by hot isostatic pressing to obtain a chemical composition of Fe-13Cr-4.0Al-0.3Ti-0.2V-2.0W-0.1Si-0.5Y-0.16%O (mass percentage, the same below) ODS-FeCrAl alloy. The alloy is forged into a Ф26mm round bar at 1150°C, and the surface defects are removed after turning, and the roughness of the billet is increased by proper grinding. Then perforate after heat treatment at 800°C / 60min to obtain a Ф24×5mm tube blank. A three-roll rolling mill is used to cold-roll the perforated tube billet. With the increase of passes, the annealing system is increased from 800°C / 1h to 1000°C / 1h, and the deformation of each pass is increased from 20% to 40%. The final rolling Cheng Ru figure 1 The shown Ф9.5×0.3mm tube. The rolling process parameters refer to Table 1. The mechanical properties at room temperature show that the yield strength of the ODS-FeCrAl alloy pipe produce...

Embodiment 2

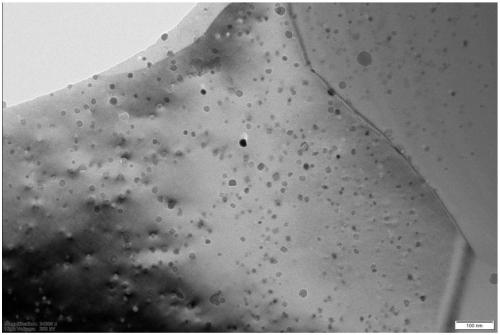

[0027] Mechanical ball milling of FeCrAl and Y using a high energy ball mill 2 o 3 powder, and extruded by a hot extrusion process to obtain an ODS-FeCrAl alloy with a chemical composition of Fe-16Cr-5.0Al-0.25Ti-0.25Zr-0.1Si-0.3Y-0.13O. The alloy is forged into a Ф24.5mm round bar at 1200°C, the surface defects are removed after turning, and then pierced after heat treatment at 700°C / 60min to obtain a Ф22×5mm tube blank. The perforated tube billet is cold-rolled by a three-roll mill. During the cold-rolling process, the annealing temperature increases from 700°C to 950°C, the holding time remains unchanged, and the deformation of each pass increases from 15% to 35%. The ODS-FeCrAl pipe because of the figure 2 The nano-oxide reinforced phase shown in the dispersion distribution has excellent mechanical properties: the tensile strength at room temperature reaches 1180 MPa, the yield strength at room temperature reaches 1100 MPa, and the elongation is 12%.

[0028] Table 2 e...

Embodiment 3

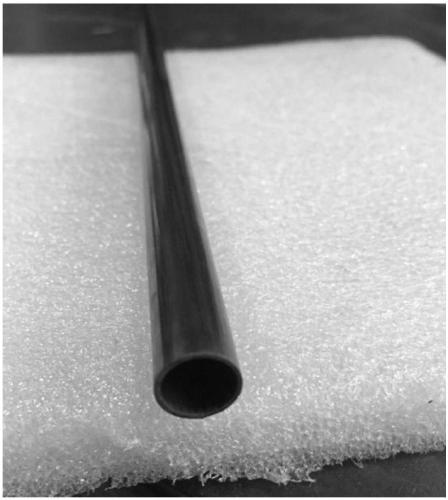

[0031] Mechanical ball milling of FeCrAl and Y using a high energy ball mill 2 o 3 powder, and thermally consolidated by hot isostatic pressing to obtain an ODS-FeCrAl alloy with a chemical composition of Fe-10Cr-4.5Al-0.2Ti-0.3Zr-1.5W-0.5Y-0.19O. The alloy is forged at 1150°C into a Ф25mm round bar, the surface defects are removed after turning, and then perforated after heat treatment at 800°C / 60min to obtain a Ф24×5mm tube blank. The perforated tube billet is cold-rolled with a three-roll mill, the annealing temperature is raised from 800°C to 1000°C, and the amount of deformation per pass is increased from 25% to 40%, and the final rolling is as follows: image 3The shown Ф10×0.5mm tube. A mechanical test was carried out on it, and the yield strength at room temperature was 1007MPa, the tensile strength was 1142MPa, and the elongation was 13.5%.

[0032] Table 3 embodiment 3 rolling process parameters

[0033]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Yield strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tensile strength at room temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com