Processing method for silicon steel ribbon iron core of direct current electric transmission and transformation radio-frequency reactor

A processing method and high-frequency electrical technology, applied in transformer/inductor parts, inductor/transformer/magnet manufacturing, circuits, etc., can solve the problems of high magnetic induction, high power, good environmental adaptability, etc. High, high power, good environmental adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

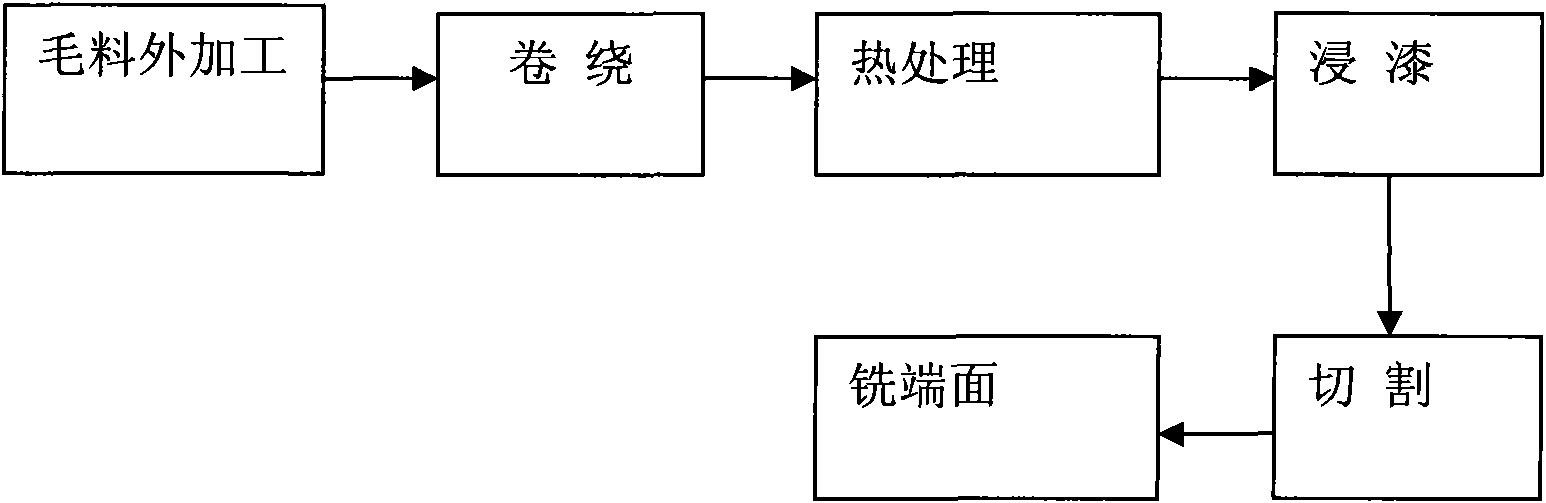

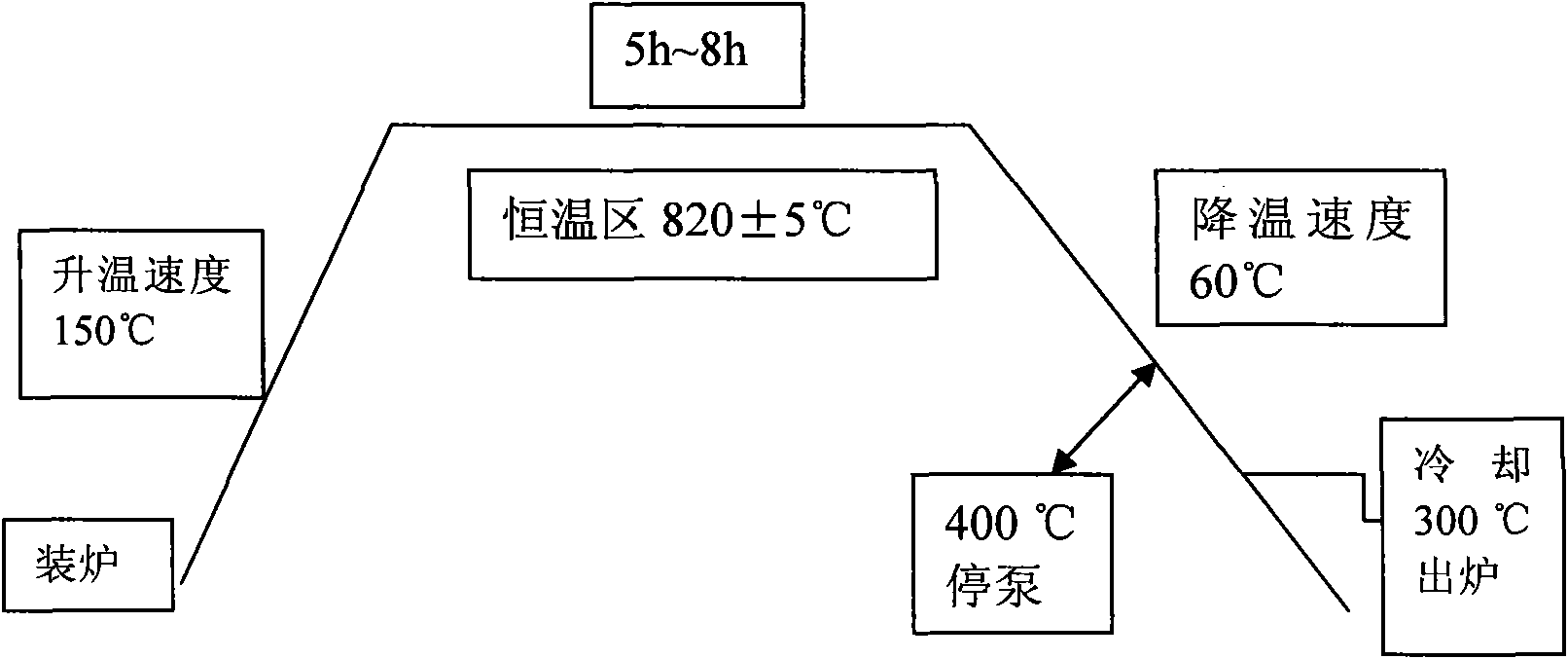

[0016] The operating process of the present invention is as follows:

[0017] 1. External processing of wool is cutting and deburring. The purpose is to cut large silicon steel strips into standard materials that meet the corresponding specifications for winding iron cores. (1) The width of the fixed hob must meet the requirements of the corresponding standard material. Load the large material into the shearing machine. After turning on the power, start the knife and try to cut 1 meter to measure whether it meets the requirements. (2) Continuous cutting is carried out after the trial cutting meets the requirements. During this process, it should be observed whether the silicon steel strip is flat and not broken, the straightness of the trimmed edge within the first meter should not be greater than 0.05mm, and the surface of the strip is free of oil. (3) The cut silicon steel strip should meet the requirements of the corresponding size regulations. The silicon steel strip has ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com