Method for hot rolling of large-opening-diameter titanium and titanium alloy thin-wall seamless pipe through jacket core bar

A large-diameter, titanium alloy technology, applied in metal rolling and other directions, can solve the problem of difficult to directly obtain thin-walled seamless pipes, and achieve the effects of low manufacturing cost, uniform heating and good quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

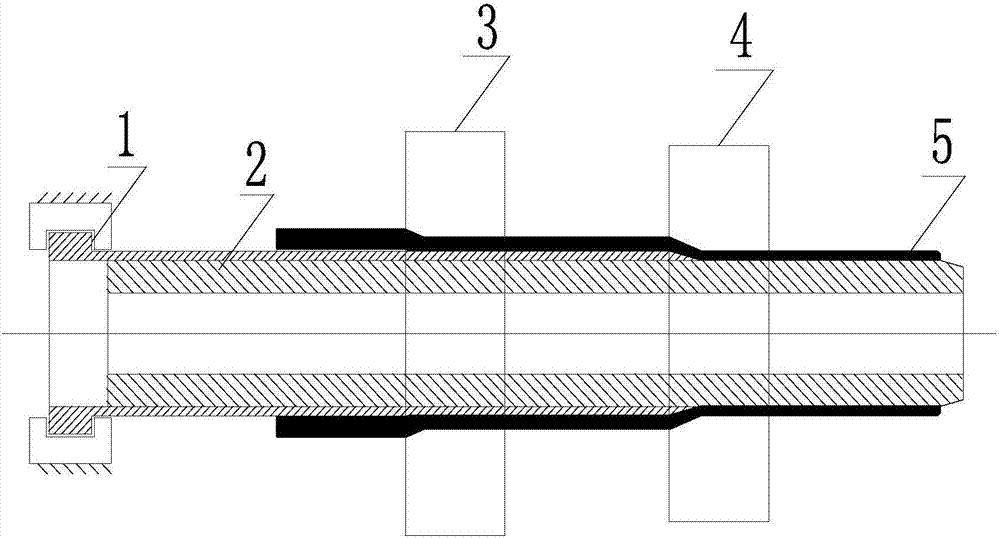

Image

Examples

Embodiment Construction

[0033] The present invention is described in further detail below.

[0034] The manufacture method of large diameter titanium and its alloy thin-walled seamless pipe of the present invention is characterized in that it comprises the following steps:

[0035] a. Sponge titanium is selected, baked at 100°C-150°C, pressed into electrode blocks with a hydraulic press, and welded into electrodes in a vacuum welding box;

[0036] b. Prepare the ingot twice by melting in a vacuum consumable electric arc furnace, control the mass percentage content of each element in the ingot according to the requirements of relevant standards, and perform peeling treatment on the secondary ingot;

[0037] c. The ingot described in step b is forged under the condition of a temperature of 750°C to 1050°C to obtain a round bar through secondary fire and upsetting, and the deformation of each fire is 30% to 80%;

[0038] d. Then the round bar is machined to obtain a bar with uniform structure and compo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com