Method for modifying surface of metal material by using surface mechanical attrition treatment

A surface mechanical grinding, metal material technology, applied in the direction of metal material coating process, coating, solid diffusion coating, etc., can solve the problems of high cost and complex process, achieve simple operation, cost saving, and improve service life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] According to the above-mentioned process method of the present invention, the pure Fe in the annealed state of the metal material is subjected to surface modification treatment.

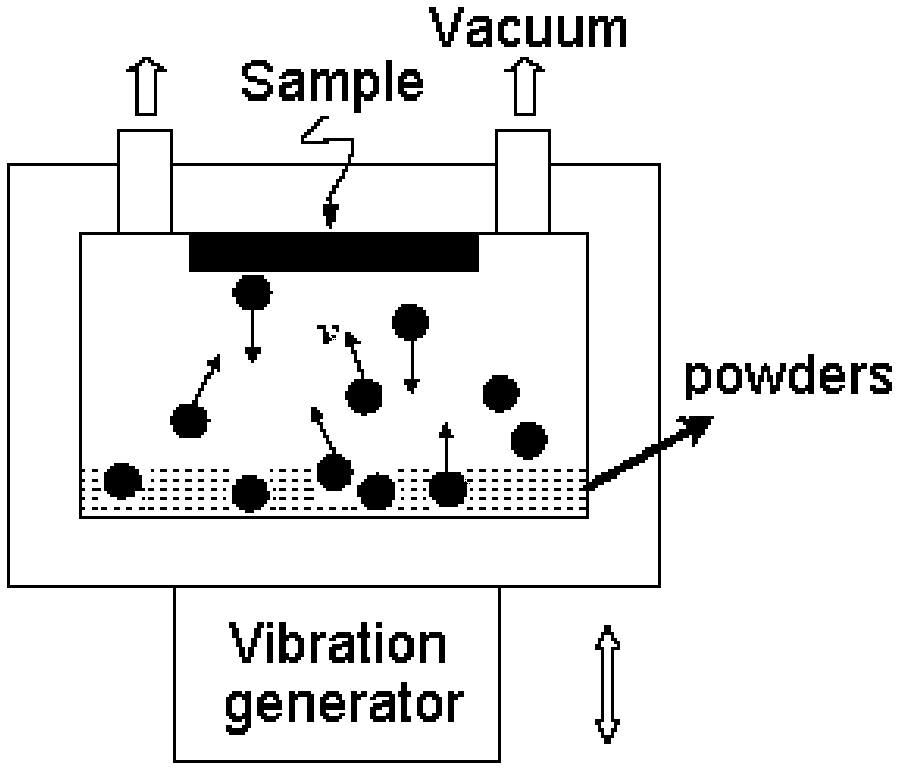

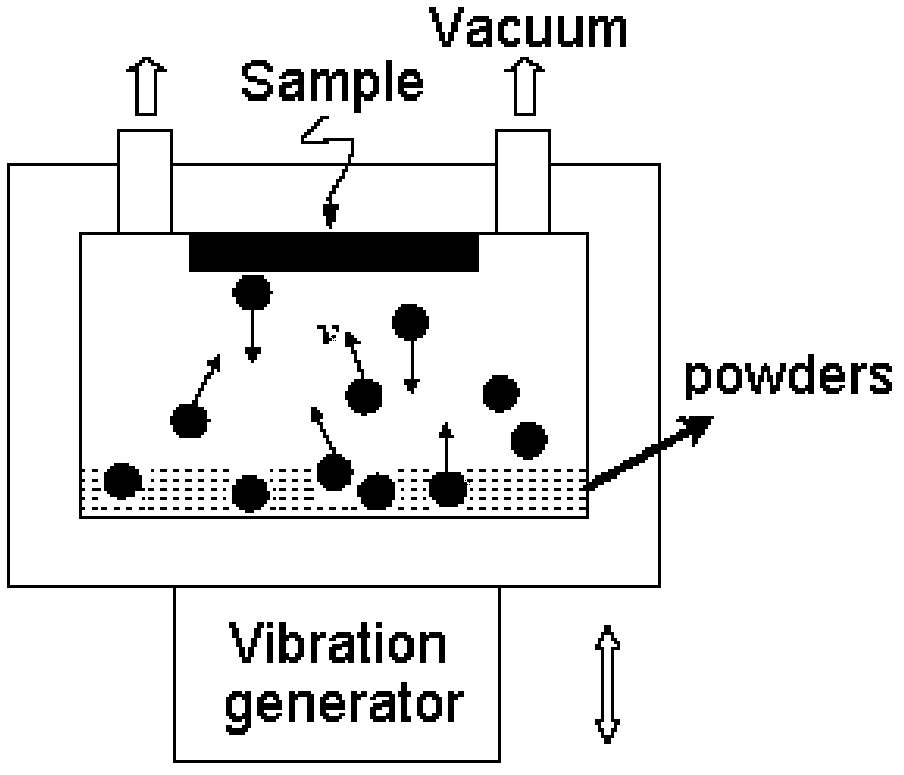

[0030] (1) Put a pure Fe (≥99.96wt%) metal material sample with a size of 80mm×80mm×8mm into a closed container containing the medium element Cr powder for SMAT treatment. The particle diameter of the Cr powder is 500nm, and the added amount The stainless steel ball at the bottom of the airtight container just had a diameter of 8 mm. The pure Fe sample was subjected to surface mechanical grinding treatment at a frequency of 50 Hz in a vacuum environment for 60 minutes.

[0031] (2) Subsequently, the pure Fe sample after the SMAT treatment was vacuum annealed at 600° C. for 60 minutes to further diffuse the Cr element into the pure Fe surface layer.

[0032] The composition analysis shows that the diffusion depth of Cr element on the surface of pure Fe reaches 18μm after vacuum annealing. The surface...

Embodiment 2

[0034] According to the process of the present invention, the surface modification treatment is performed on the annealed state 45 steel of the metal material.

[0035] (1) Put a 45 steel sample with a size of 80mm×80mm×8mm into a closed container containing Cr powder as a medium element for SMAT treatment. The particle diameter of the Cr powder is 500nm, and the amount added just so that it does not pass the bottom of the closed container The diameter of the stainless steel ball is 8mm; the 45 steel sample is subjected to SMAT treatment in a vacuum environment at a frequency of 50 Hz for 60 minutes.

[0036] (2) The SMAT-treated 45 steel samples were subsequently vacuum annealed at 300°C, 400°C and 500°C for 30 minutes.

[0037] The XRD phase analysis showed that (Cr, Fe) appeared on the surface of the sample after vacuum annealing at 400℃ and 500℃ for 30 min. 23 C 6 And (Cr, Fe) 7 C 3 The new metal compound makes the surface hardness of the sample up to 4.8 GPa, while the hardness ...

Embodiment 3

[0039] According to the process method of the present invention, surface modification treatment is performed on the annealed pure Ni.

[0040] (1) Put a pure Ni (≥99.96wt%) sample of a metal material with a size of 80mm×80mm×8mm into a closed container filled with ultra-fine medium element Fe powder for SMAT treatment, and the amount added is just enough to make it do not pass the closed container The stainless steel ball at the bottom has a diameter of 8mm; the pure Ni sample is subjected to SMAT treatment in a vacuum environment at a frequency of 50 Hz for 60 minutes.

[0041] (2) Subsequently, the SMAT-treated metal material samples were vacuum annealed at 450°C, 550°C, and 650°C for 30 minutes.

[0042] The XRD phase analysis showed that after vacuum annealing at 550℃ for 30 minutes, a new Ni-Fe alloy phase appeared on the surface of the metal material sample, while after vacuum annealing at 650℃ for 30 min, the pure Ni phase basically disappeared, and the surface of the metal ma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Surface hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com