Molybdenum-tungsten alloy sputtering target material for flat panel display and preparation method thereof

A flat-panel display, molybdenum-tungsten alloy technology, applied in the directions of metal rolling, metal rolling, sputtering coating, etc., can solve the problem of inability to obtain, achieve lower sintering temperature, uniform sputtering coating layer, improve sputtering coating effect of speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

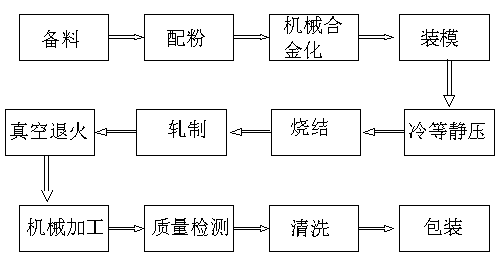

Image

Examples

Embodiment 1

[0041] 1) Material preparation: The powder used is molybdenum powder and tungsten powder. The physical properties of the powder are: the Mo content of the molybdenum powder is ≥99.95%, and the particle size is 3 μm; the W content of the tungsten powder is ≥99.95%, and the particle size is 3 μm.

[0042] 2) Powder blending: Weigh the molybdenum powder and tungsten powder according to the following mass percentage ratio, the content of molybdenum powder is 80%, and the content of tungsten powder is 20%, and mix the two evenly.

[0043] 3) Mechanical alloying: Mechanical alloying is the use of high-energy ball milling, crushing, cold welding and low-temperature solid-state reaction under the action of mechanical force to synthesize nano-scale molybdenum-tungsten alloy powder. Mix molybdenum powder and tungsten powder in proportion, and ball mill in a planetary high-energy ball mill. The ball milling is carried out in a vacuum environment. The ball-to-material ratio is 1:1, and th...

Embodiment 2

[0069] 1) Material preparation: The powder used is molybdenum powder and tungsten powder. The physical properties of the powder are: the Mo content of the molybdenum powder is ≥99.95%, and the particle size is 5 μm; the W content of the tungsten powder is ≥99.95%, and the particle size is 5 μm.

[0070] 2) Powder blending: Weigh molybdenum powder and tungsten powder according to the following mass percentage ratio, the content of molybdenum powder is 96.5%, and the content of tungsten powder is 3.5%, and mix them evenly.

[0071] 3) Mechanical alloying: Mechanical alloying is the use of high-energy ball milling, crushing, cold welding and low-temperature solid-state reaction under the action of mechanical force to synthesize nano-scale molybdenum-tungsten alloy powder. Mix molybdenum powder and tungsten powder in proportion, and ball mill in a planetary high-energy ball mill. The ball milling is carried out in a vacuum environment. The ball-material ratio is 1:1.5, and the bal...

Embodiment 3

[0097] 1) Material preparation: The powder used is molybdenum powder and tungsten powder. The physical properties of the powder are: the Mo content of the molybdenum powder is ≥99.95%, and the particle size is 3.4 μm; the W content of the tungsten powder is ≥99.95%, and the particle size is 3.2 μm.

[0098] 2) Powder blending: Weigh molybdenum powder and tungsten powder according to the following mass percentage ratio, the content of molybdenum powder is 90%, and the content of tungsten powder is 10%, mix the two evenly.

[0099] 3) Mechanical alloying: Mechanical alloying is the use of high-energy ball milling, crushing, cold welding and low-temperature solid-state reaction under the action of mechanical force to synthesize nano-scale molybdenum-tungsten alloy powder. Mix molybdenum powder and tungsten powder in proportion, and ball mill in a planetary high-energy ball mill. The ball milling is carried out in a vacuum environment. The ball-to-material ratio is 1:1, and the ba...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com