Special Ti-6Al-3V welding wire for Ti-6Al-4V ELI titanium alloy and machining process of special Ti-6Al-3V welding wire

A technology of ti-6al-4veli and processing technology, which is applied in the field of titanium alloy welding wire, can solve the problems that the quality of welds cannot meet the requirements of assessment indicators, etc., and achieve the improvement of welding quality and true sphericity, and the improvement of mechanical properties. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The embodiments described below are only some of the embodiments of the present invention, not all of them. Based on the embodiments of the present invention, all other embodiments obtained by persons of ordinary skill in the art without creative work belong to the protection scope of the present invention

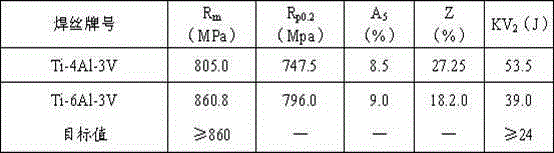

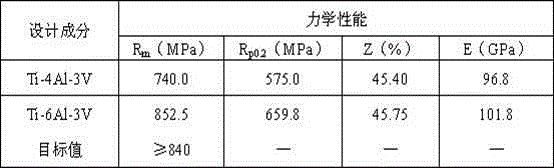

[0022] a) According to the design composition wt.% of Ti-6Al-3V welding wire: Al 6.0, V 3.0, Fe<0.20, O<0.13, the balance is Ti. Calculate the raw material weight ratio of Al-V master alloy, pure metal aluminum and sponge titanium, then put the prepared raw materials into the vacuum consumable electric arc furnace, and make Φ500mm~Φ800mm titanium alloy castings through 3 times of vacuum consumable melting ingot. According to the test, the alloy composition wt.% of titanium alloy ingot is: Al 6.1, V 2.9, Fe 0.02, O 0.06-0.07, and the balance is Ti.

[0023] b) The Φ600mm titanium alloy ingot is forged into a Φ150mm titanium alloy billet by using a fast forging mach...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com