Method for preparing high aspect ratio metal microgratings on metal substrate

A metal substrate, high aspect ratio technology, applied in the direction of diffraction grating, electrolytic process, electroforming, etc., can solve the problems of complex process, inclined grating side wall, high cost, etc., and achieve simple preparation process, high dimensional accuracy, and mechanical strength high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The specific implementation manners of the present invention will be described in detail below in combination with the above technical solutions and accompanying drawings.

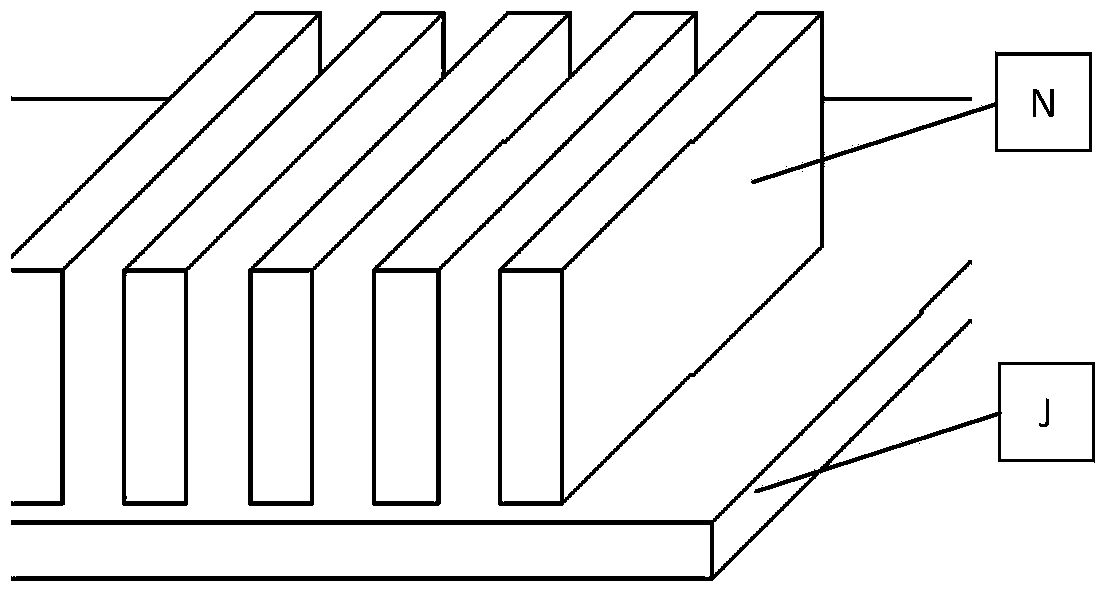

[0023] For example: high-aspect-ratio metal micro-gratings are prepared on high-purity nickel plates with a nickel content of 99.99%. figure 1 As shown, its comprehensive dimensions are as follows: the width of the grating boss is 65 μm, the length is 900 μm, the height is 243 μm, and the grating period is 130 μm. Nickel plate size is 60×20×3mm 3 , the specific steps for preparing the structure are as follows:

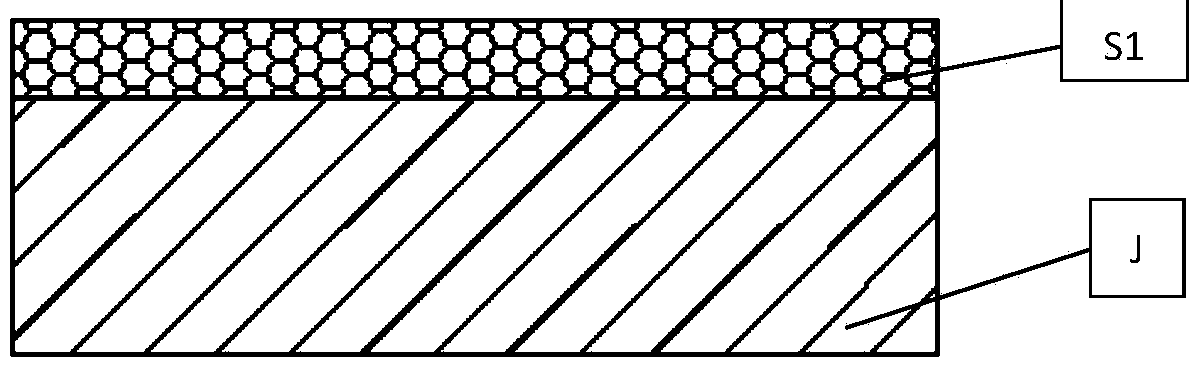

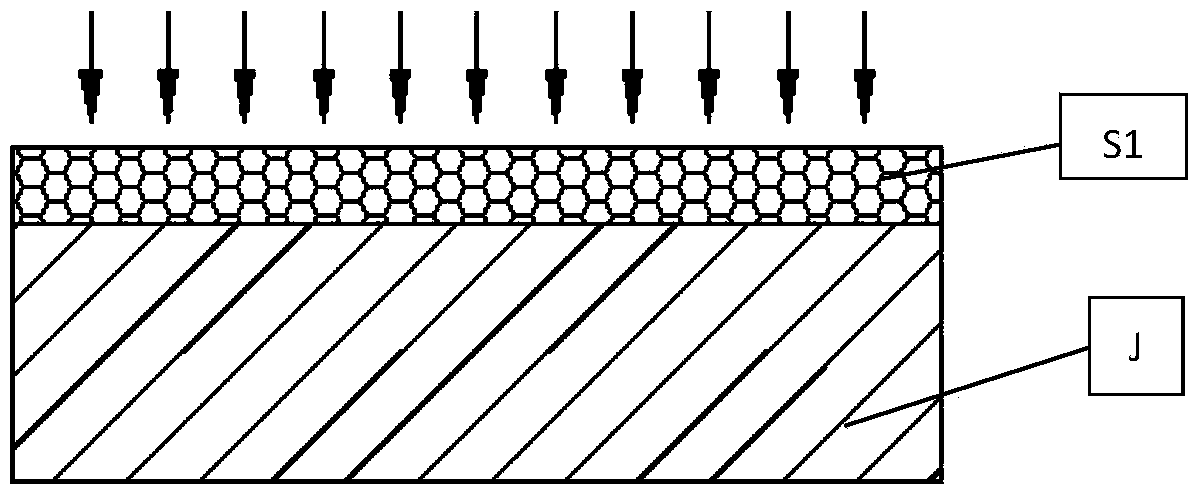

[0024] (1) Substrate pretreatment: Grind and polish on a grinding and polishing machine first, and finally the surface roughness of the nickel substrate reaches below 0.04 μm; then wipe the substrate surface with acetone cotton balls, and then perform ultrasonic cleaning in acetone and ethanol respectively After 10 minutes, rinse with pure water and blow dry, and finally bake in an oven at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com