Method for manufacturing high-roughness electronic copper foil for ceramic-based high-frequency electronic copper-clad plate

A manufacturing method and technology of electronic copper foil, which are applied in the manufacture of printed circuits, the manufacture of printed circuit precursors, electrical components, etc. Good uniformity, improved high temperature oxidation resistance, high consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

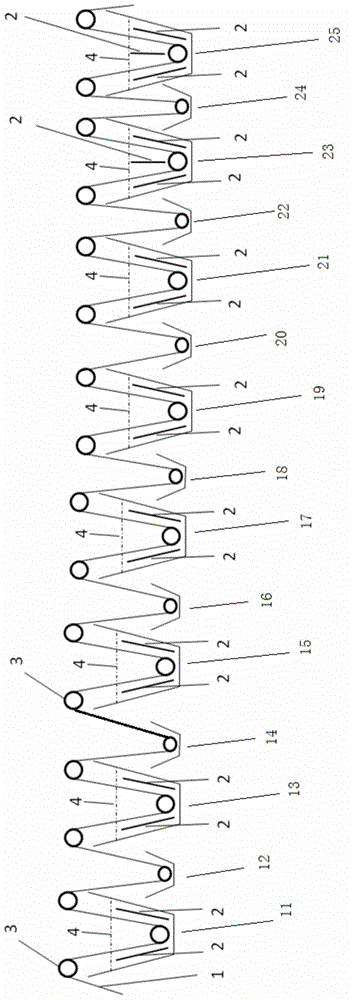

Image

Examples

Embodiment 1

[0029] Raw foil process: electroplating in the raw foil solution to generate raw foil, the current density of the electroplating operation in this process is 7100A / m 2 , the temperature of the raw foil liquid is controlled at 49°C, the concentration of sulfuric acid in the raw foil liquid is 145g / L, the concentration of divalent copper ions is 65g / L, and the flow rate is 46m 3 / h, the raw foil liquid also includes a raw foil additive, which contains sodium dodecylsulfonate at a concentration of 2.6g / L, medicinal dextrin at a concentration of 0.5g / L, and 0.25g / The hydrochloric acid of the high molecular weight gelatin (molecular weight 200000) of L concentration and 22mg / L concentration;

[0030] The first roughening process: after pickling the copper foil produced in the raw foil process, it is electroplated in the roughening solution, and the current density of the first stage of the electroplating operation is 30A / dm 2 , the current density of the second stage is 8A / dm 2 ...

Embodiment 2

[0042] Raw foil process: electroplating in the raw foil solution to generate raw foil, the current density of the electroplating operation in this process is 7500A / m 2 , the temperature of the raw foil liquid is controlled at 50°C, the concentration of sulfuric acid in the raw foil liquid is 147g / L, the concentration of divalent copper ions is 67g / L, and the flow rate is 47m 3 / h, the raw foil liquid also includes a raw foil additive, which contains sodium dodecylsulfonate at a concentration of 2.8g / L, medicinal dextrin at a concentration of 0.6g / L, and 0.27g / The hydrochloric acid of the high molecular weight gelatin (molecular weight 100000) of L concentration and 23mg / L concentration;

[0043] The first roughening process: after pickling the copper foil produced in the raw foil process, it is electroplated in the roughening solution, and the current density of the first stage of the electroplating operation is 29A / dm 2 , the current density of the second stage is 7A / dm 2 ...

Embodiment 3

[0055] Raw foil process: electroplating in the raw foil solution to generate raw foil, the current density of the electroplating operation in this process is 8000A / m 2 , the temperature of the raw foil liquid is controlled at 52°C, the concentration of sulfuric acid in the raw foil liquid is 150g / L, the concentration of divalent copper ions is 69g / L, and the flow rate is 48m 3 / h, the raw foil liquid also includes a raw foil additive, which contains sodium dodecylsulfonate at a concentration of 3.0g / L, medicinal dextrin at a concentration of 0.7g / L, and 0.28g / The hydrochloric acid of the high molecular weight gelatin (molecular weight 200000) of L concentration and 30mg / L concentration;

[0056] The first roughening process: after pickling the copper foil produced in the raw foil process, it is electroplated in the roughening solution, and the current density of the first stage of the electroplating operation is 31A / dm 2 , the current density of the second stage is 8A / dm 2 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com