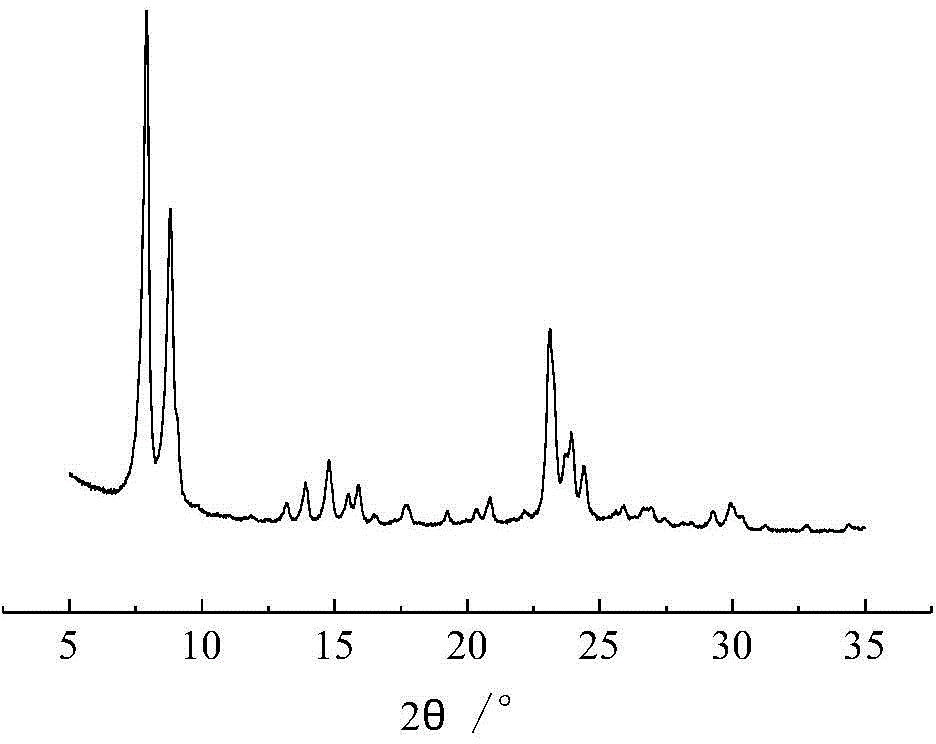

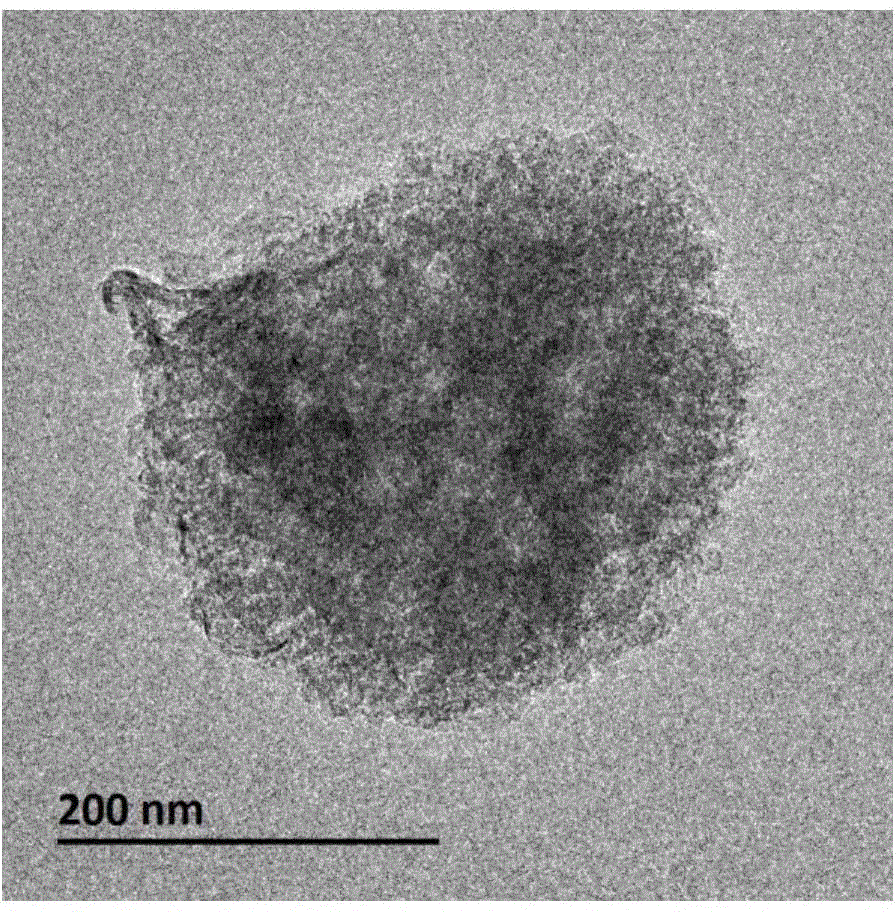

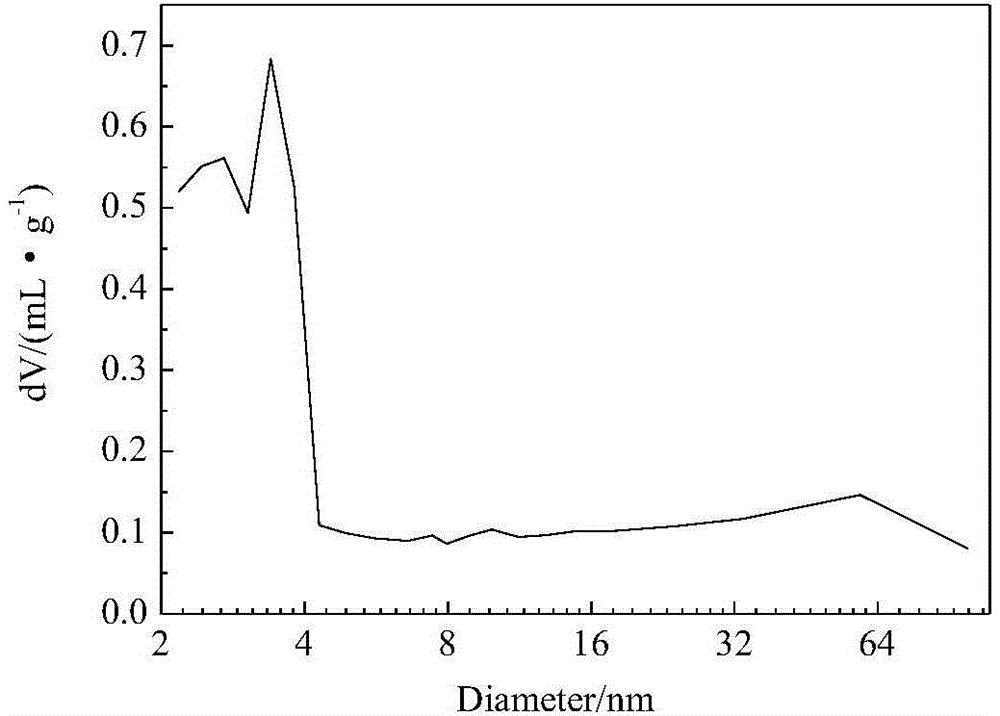

Hierarchical pore titanium-silicon molecular sieve and synthesis method thereof

A technology of titanium-silicon molecular sieve and synthesis method, which is applied in the direction of crystalline aluminosilicate zeolite, etc., can solve the problems of low crystallinity of titanium-silicon molecular sieve and affect the activity of molecular sieve, and achieve high selective oxidation activity, uniform particle size distribution, and specific surface area big effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] On the other hand, the present invention also provides a kind of synthetic method of hierarchical porous titanium silicon molecular sieve, comprises the following steps:

[0035] (1) Mix the silicon source, the structure directing agent, the titanium source, water, silylating agent with the natural polymer compound and / or the modified natural polymer compound to obtain a reaction mixture, in which SiO 2 :R:TiO 2 :H 2 The molar ratio of O:B is 1:(0.001-5):(0.001-0.1):(5-400):(0.001-0.5), natural polymer compound and / or modified natural polymer compound in the reaction mixture with SiO 2 The weight ratio is 0.001-1; Wherein, R represents the molar number of the structure directing agent in the reaction mixture, and B represents the molar number of the silylating agent in the reaction mixture;

[0036] (2) crystallizing the reaction mixture obtained in step (1) in a pressure-resistant airtight container at 90-230° C. and autogenous pressure for 1-240 hours to obtain a c...

Embodiment 1

[0070] Under stirring conditions, mix ethyl orthosilicate, tetrapropylammonium hydroxide, tetrabutyl titanate and deionized water to obtain a molar ratio of SiO 2 : Structure directing agent: TiO 2 :H 2 O=1:0.2:0.025:50 mixture. Press SiO again 2 The molar ratio to silylating agent is 1:0.1, SiO 2 The weight ratio of the natural polymer compound is 1:0.1, add quaternized cellulose and N-phenyl-3-aminopropyltrimethoxysilane to the titanium-silicon molecular sieve precursor gel mixture, and stir evenly Finally, the obtained silylating agent and the titanium-silicon molecular sieve precursor treated with the modified natural polymer compound were transferred to a pressure-resistant stainless steel reaction kettle; under stirring conditions, heated to 170°C and crystallized under autogenous pressure for 24 hours.

[0071] After the stainless steel pressure-resistant reactor was lowered to room temperature, the obtained unroasted titanium-silicon molecular sieve was recovered, ...

Embodiment 2

[0073] Under stirring conditions, mix propyl orthosilicate, tetraethylammonium hydroxide, tetraethyl titanate and deionized water to obtain a molar ratio of SiO 2 : Structure directing agent: TiO 2 :H 2 O=1:0.01:0.01:16 mixture. Press SiO again 2 The molar ratio to silylating agent is 1:0.04, SiO 2 The weight ratio of the natural polymer compound is 1:0.05. Add cellulose and trimethylchlorosilane to the titanium-silicon molecular sieve precursor gel mixture. After stirring evenly, the obtained silylating agent and natural polymer compound are treated The titanium-silicon molecular sieve precursor was transferred to a pressure-resistant stainless steel reactor; under stirring conditions, it was heated to 190°C and crystallized under autogenous pressure for 48h.

[0074] After the stainless steel pressure-resistant reactor was lowered to room temperature, the obtained unroasted titanium-silicon molecular sieve was recovered, dried at 130°C for 4 hours, and then calcined at 5...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com