Method and apparatus for olefin superposition

An olefin hydration and olefin technology, which is applied in the production of liquid hydrocarbon mixtures, hydrocarbon oil treatment, hydrocarbon oil treatment products, etc., can solve the problems of high requirements and complicated raw material refining process, achieve low cost, improve softening status, and improve catalytic performance. Active and Selective Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0085] According to an embodiment of the present invention, the metal content in the laminated raw material is 1 μg / g-10 μg / g, preferably 1.5 μg / g-10 μg / g, more preferably 2 μg / g-6 μg / g.

[0086] According to one embodiment of the present invention, in the laminated raw materials, the content of basic nitrogen compounds is 1 μg / g to 10 μg / g, preferably 1.5 μg / g to 10 μg / g, more preferably 2 μg / g to 6 μg / g g.

[0087] According to the aforementioned embodiment, the strongly acidic cation exchange resin catalyst loaded in the first reaction zone can effectively remove metals in the superimposed raw materials, and can also remove basic nitrides in the raw materials. Generally speaking, the contents of metals and basic nitrides can be easily reduced to less than 1 μg / g after the laminated raw materials pass through the first reaction zone.

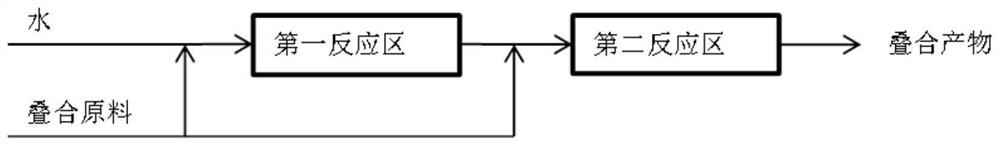

[0088] The present invention also provides a device for realizing the above method, which is characterized in that it includes a first react...

Embodiment 1

[0097] refer to figure 1 The process flow shown, the experimental device is established in the laboratory, the first fixed bed reactor (ie the first reaction zone) with an inner diameter of φ19mm and a length of 600mm and the second fixed bed reactor with an inner diameter of φ32mm and a length of 1000mm (i.e. the second reaction zone) in series, and 50mL KC110 macroporous strong-acid cation exchange resin (produced by Hebei Kairui Environmental Protection Technology Co., Ltd., with a mass exchange capacity of 5.4mmolH) was loaded into the first fixed-bed reactor + / g, water content 35m%), in the second fixed-bed reactor, load 200mL RSPA-01 type loaded solid phosphoric acid catalyst (production of Sinopec Changling Catalyst Branch Company, total phosphoric acid content 65m%, free phosphoric acid content 18m%) .

[0098] Mixed C4 (that is, superimposed raw material) is taken from the C4 fraction of a catalytic cracking unit of a company, and its composition (mass fraction) is:...

Embodiment 2

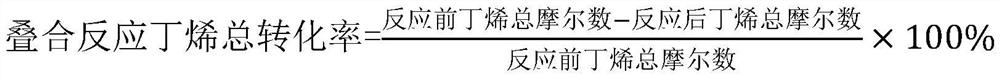

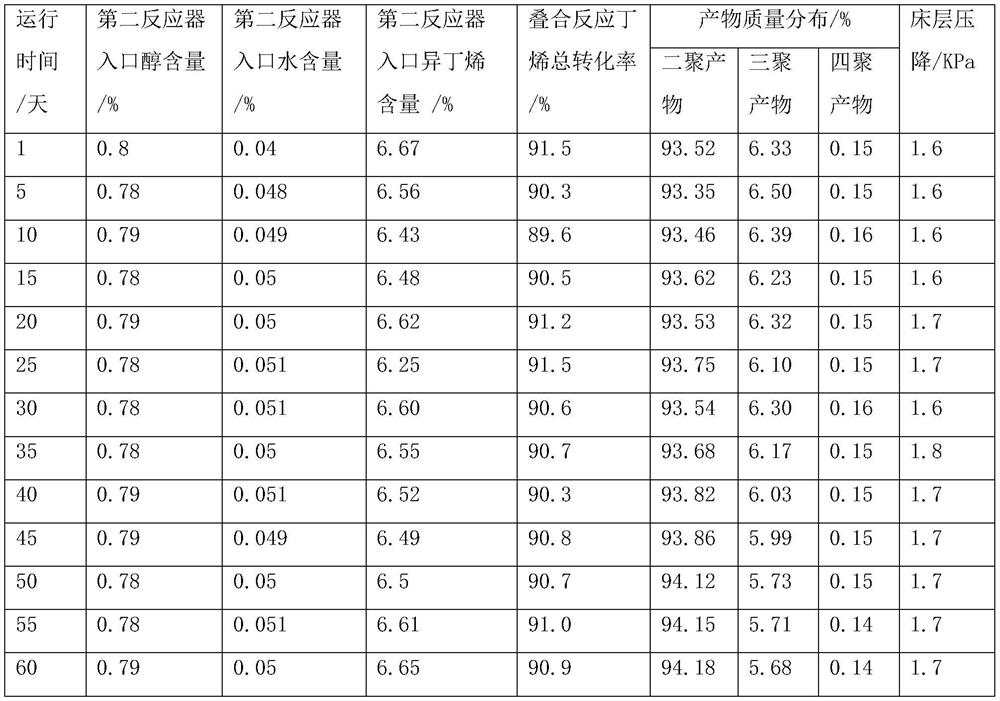

[0128] The difference between this embodiment and Example 1 is that all the C4 raw materials enter from the first fixed-bed reactor, and the flow rate is 200g / h, that is, the feed of the second fixed-bed reactor is all from the first fixed-bed reactor. output. Other parts not mentioned in this embodiment are the same as in Embodiment 1. The results of running for 2 months are shown in Table 7.

[0129] Table 7

[0130]

[0131] The experimental product was collected, and the unreacted C4 was removed by rectification, and the oil product was fully analyzed. The result showed that the octane number of the oil product was RON103, and the dry point was 201°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Do it | aaaaa | aaaaa |

| Do it | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com