Catalyst for preparing low-carbon olefin through carbon dioxide hydrogenation and preparation method thereof

A carbon dioxide and low-carbon olefin technology, which can be used in metal/metal oxide/metal hydroxide catalysts, hydrocarbon production from carbon oxides, carbon compound catalysts, etc., and can solve the problems of poor activity and selectivity of low-carbon olefin catalysts. Achieve the effect of improving catalytic activity and selectivity, enhancing adsorption, and ensuring controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

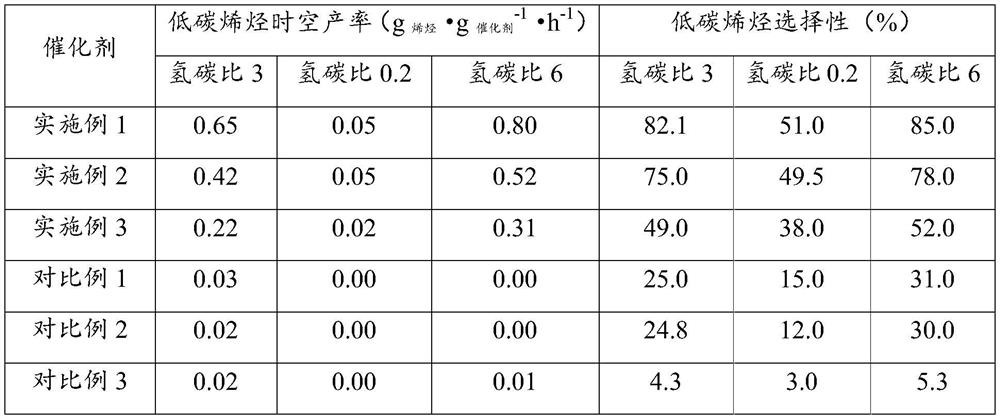

Examples

Embodiment 1

[0041] This embodiment provides a catalyst for the hydrogenation of carbon dioxide to light olefins, the raw material of which includes Fe(NO 3 ) 3 , FeSO 4 , Mg(NO 3 ) 2 , triethylamine and ammonium bicarbonate.

[0042] The present embodiment also provides that the preparation method of above-mentioned catalyst comprises the following steps:

[0043] (1) Fe(NO 3 ) 3 , FeSO 4 , Mg(NO 3 ) 2 , adding water to prepare Fe 3+ , Fe 2 and Mg 2+ Mixed solutions A with molar concentrations of 0.08mol / L, 0.02mol / L, and 0.1mol / L respectively, set aside;

[0044] Mix triethylamine, ammonium bicarbonate and water to prepare mixed solution B, and the molar concentrations of triethylamine and ammonium bicarbonate in mixed solution B are 0.1mol / L and 0.1mol / L respectively, and set aside;

[0045] Add 50mL mixed solution B to 200mL deionized water, and add mixed solution A and mixed solution B dropwise at 60°C under an atmosphere of carbon dioxide at the same time, at a rate of 1...

Embodiment 2

[0048] This example provides a catalyst for the hydrogenation of carbon dioxide to produce low-carbon olefins, the raw material of which includes FeCl 3 , FeCl 2 , MgCl 2 , diethylamine and ammonium bicarbonate.

[0049] The present embodiment also provides that the preparation method of above-mentioned catalyst comprises the following steps:

[0050] (1) Take FeCl 3 , FeCl 2 , MgCl 2 , adding water to prepare Fe 3+ , Fe 2 and Mg 2+ Mixed solutions A with molar concentrations of 0.1mol / L, 0.35mol / L, and 0.15mol / L respectively, set aside;

[0051] Mix diethylamine, ammonium bicarbonate and water to prepare mixed solution B. The molar concentrations of diethylamine and ammonium bicarbonate in mixed solution B are 1mol / L and 0.01mol / L respectively, and set aside;

[0052] Add 20mL of mixed solution B to 200mL of deionized water, and add mixed solution A and mixed solution B dropwise at 90°C under an atmosphere of carbon dioxide at the same time, at a rate of 3mL / min and ...

Embodiment 3

[0055] This embodiment provides a catalyst for producing low-carbon olefins by hydrogenation of carbon dioxide, the raw material of which includes Fe 2 (SO 4 ) 3 , FeSO 4 , MgSO 4 , tetraethylammonium hydroxide and ammonium bicarbonate.

[0056] The present embodiment also provides that the preparation method of above-mentioned catalyst comprises the following steps:

[0057] (1) Take Fe 2 (SO 4 ) 3 , FeSO 4 , MgSO 4 , adding water to prepare Fe 3+ , Fe 2 and Mg 2+ Mixed solution A with a molar concentration of 0.003mol / L, 0.005mol / L, and 0.004mol / L respectively, set aside;

[0058] Tetraethylammonium hydroxide solution, ammonium bicarbonate and water are mixed and formulated into mixed solution B, and the molar concentrations of tetraethylammonium hydroxide solution and ammonium bicarbonate in mixed solution B are respectively 0.01mol / L, 1mol / L, spare;

[0059] Add 50mL of mixed solution B to 200mL of deionized water, and add mixed solution A and mixed solution ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com