Resin, pigment dispersion liquid, coloring curable composition, color filter produced by using composition, and method for producing color filter

一种固化性组合物、制造方法的技术,应用在滤光片、有机染料、图纹面的照相制版工艺等方向,能够解决图案形成变困难、分散性·分散稳定性·显影性变差等问题,达到分散性·分散稳定性优异、色特性良好、色纯度高的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0442] Hereinafter, although an Example demonstrates this invention in more detail, this invention is not limited to this.

[0443] It should be noted that, in the examples, the acid value and the amine value use the potential difference method (solvent tetrahydrofuran / water=100 / 10 (volume ratio), titration solution 0.01N sodium hydroxide aqueous solution (acid value) 0.01N hydrochloric acid ( Amine value)) to decide. However, in Example 18 and Example 29, instead of the 0.01N aqueous sodium hydroxide solution, the titration was performed with a 0.01N sodium methoxide dioxane solution system.

Synthetic example 1

[0444] (Synthesis example 1) Synthesis of polyester (i-1)

[0445] 6.4 g of n-octanoic acid, 200 g of ε-caprolactone, and 5 g of tetrabutoxytitanium (IV) were mixed, heated at 160° C. for 8 hours, and then cooled to room temperature to obtain polyester (i-1).

[0446] The diagram is shown below.

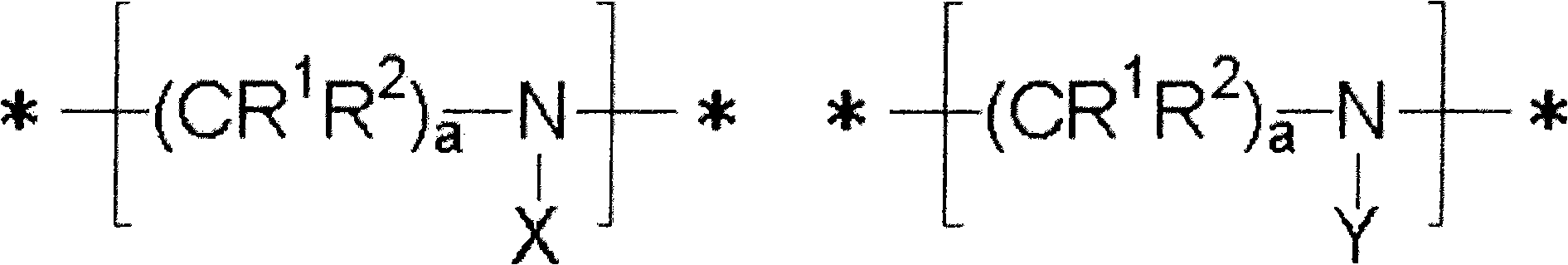

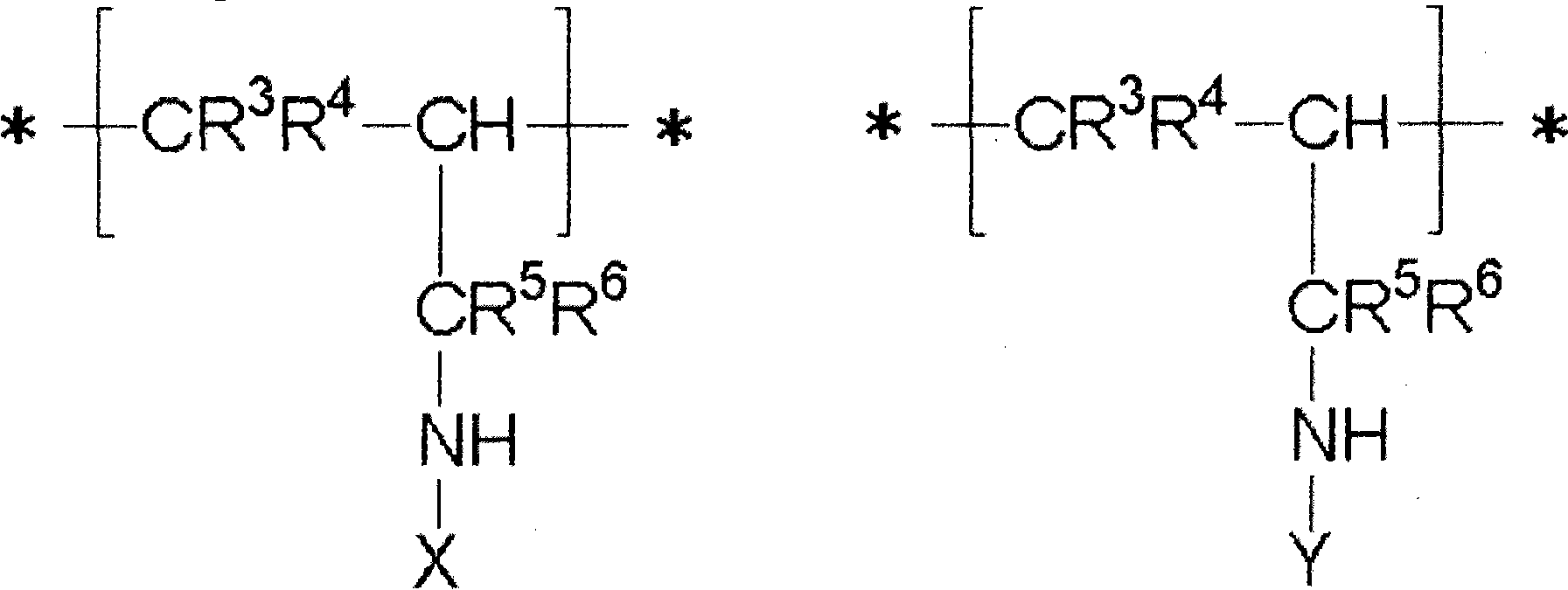

[0447] [chem 36]

[0448]

Synthetic example 2~10

[0450] Polyesters (i-2) to (i-10) were obtained in the same manner as in Synthesis Example 1 except that the amount of preparation was described in Table 1. The number-average molecular weight and weight-average molecular weight of the resins obtained in these synthesis examples were measured by the GPC method already described. The results are shown in Table 1 below. In addition, the number of lactone repeating units calculated from the raw material charging ratio is also shown in Table 1 below.

[0451] 【Table 1】

[0452]

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com