Iron based amorphous/alumina ceramic composite powder and preparation method and applications thereof

A kind of technology of alumina ceramics and iron-based amorphous, which is applied in the direction of coating, metal material coating process, fusion spraying, etc., can solve the problems of poor wear resistance and high preparation cost, and achieve excellent wear resistance and improve Glass-forming ability and toughness improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] An iron-based amorphous / alumina ceramic composite powder, the preparation method comprising the following steps:

[0033] Step 1: Weigh 75.8 parts of low-carbon ferrochrome, 8.5 parts of high-carbon ferrochrome, 3.7 parts of cobalt, 5.1 parts of electrolytic nickel, 19.2 parts of ferro-niobium, 9.9 parts of ferrosilicon, 40.7 parts of ferro-molybdenum, 9.2 parts of boron iron, 7.6 parts of boron carbide, 10.8 parts of iron, 6.8 parts of nano-sized alumina particles;

[0034] Step 2: Add low-carbon ferrochrome, high-carbon ferrochrome, cobalt, electrolytic nickel, ferro-niobium, ferrosilicon, ferro-molybdenum, ferro-boron, boron carbide and iron into the induction induction cooker, heat to 2250 ℃ to melt all the materials, and induce The heating rate of the induction cooker is 60-80°C / min;

[0035] Step 3: Cool the completely melted molten metal at a cooling rate of 400-600°C / h, add half of the nano-sized alumina particles when the temperature of the molten metal drops ...

Embodiment 2

[0046] An iron-based amorphous / alumina ceramic composite powder, the preparation method comprising the following steps:

[0047] Step 1: Weigh 75.8 parts of low-carbon ferrochrome, 8.5 parts of high-carbon ferrochrome, 3.7 parts of cobalt, 5.1 parts of electrolytic nickel, 19.2 parts of ferro-niobium, 9.9 parts of ferrosilicon, 40.7 parts of ferro-molybdenum, 9.2 parts of boron iron, 7.6 parts of boron carbide, 10.8 parts of iron, 6.1 parts of nano-sized alumina particles;

[0048] Step 2: Add low-carbon ferrochrome, high-carbon ferrochrome, cobalt, electrolytic nickel, ferro-niobium, ferrosilicon, ferro-molybdenum, ferro-boron, boron carbide and iron into the induction induction cooker, heat to 2250 ℃ to melt all the materials, and induce The heating rate of the induction cooker is 60-80°C / min;

[0049] Step 3: Cool the completely melted molten metal at a cooling rate of 400-600°C / h, add half of the nano-sized alumina particles when the temperature of the molten metal drops ...

Embodiment 3

[0058] An iron-based amorphous / alumina ceramic composite powder, the preparation method comprising the following steps:

[0059] Step 1: Weigh 75.8 parts of low-carbon ferrochrome, 8.5 parts of high-carbon ferrochrome, 3.7 parts of cobalt, 5.1 parts of electrolytic nickel, 19.2 parts of ferro-niobium, 9.9 parts of ferrosilicon, 40.7 parts of ferro-molybdenum, 9.2 parts of boron iron, 7.6 parts of boron carbide, 10.8 parts of iron, 8.1 parts of nano-sized alumina particles;

[0060] Step 2: Add low-carbon ferrochrome, high-carbon ferrochrome, cobalt, electrolytic nickel, ferro-niobium, ferrosilicon, ferro-molybdenum, ferro-boron, boron carbide and iron into the induction induction cooker, heat to 2250 ℃ to melt all the materials, and induce The heating rate of the induction cooker is 60-80°C / min;

[0061] Step 3: Cool the completely melted molten metal at a cooling rate of 400-600°C / h, add half of the nano-sized alumina particles when the temperature of the molten metal drops ...

PUM

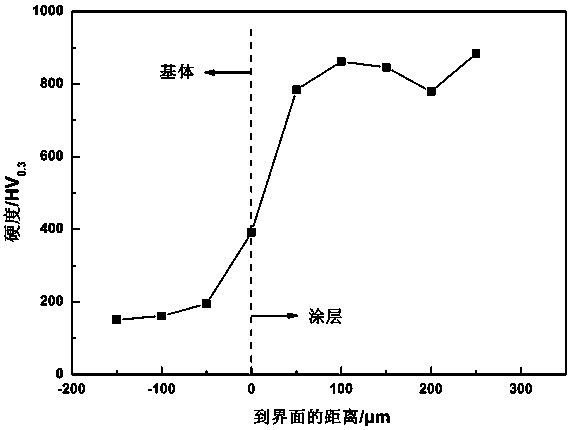

| Property | Measurement | Unit |

|---|---|---|

| microhardness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com