(ZrM)-(CuN)-Ni-Al-(Re) amorphous alloy, and preparation method and application thereof

An amorphous alloy and alloy composition technology, which is applied in the field of Zr-based amorphous alloy manufacturing to achieve the effects of excellent mechanical properties, broad application prospects, high amorphous forming ability and manufacturability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

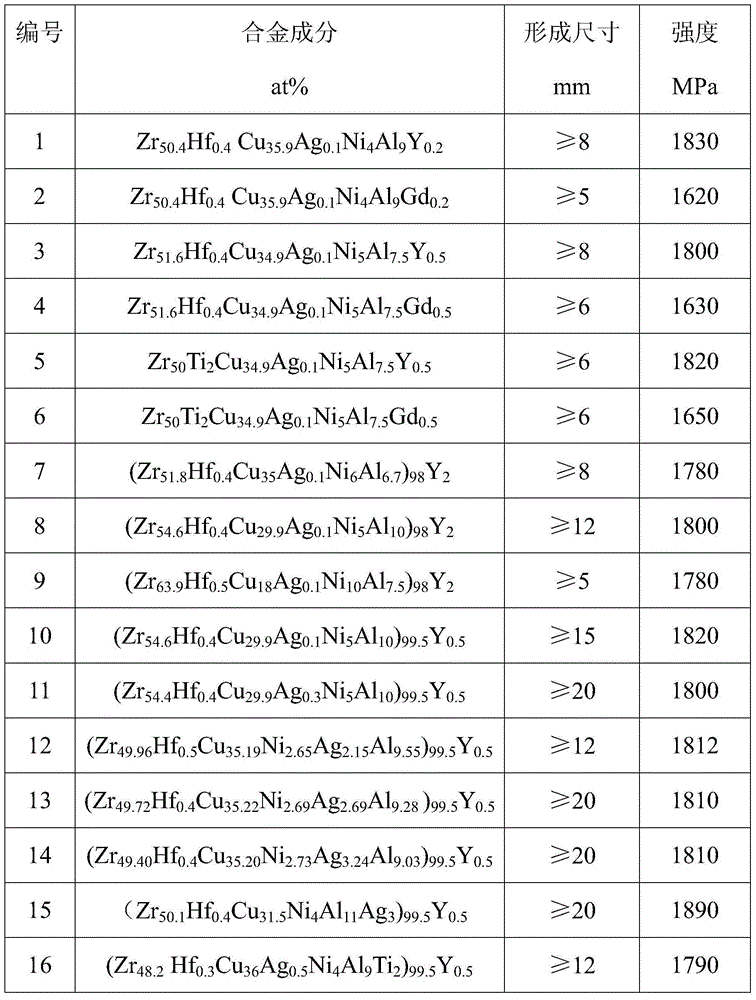

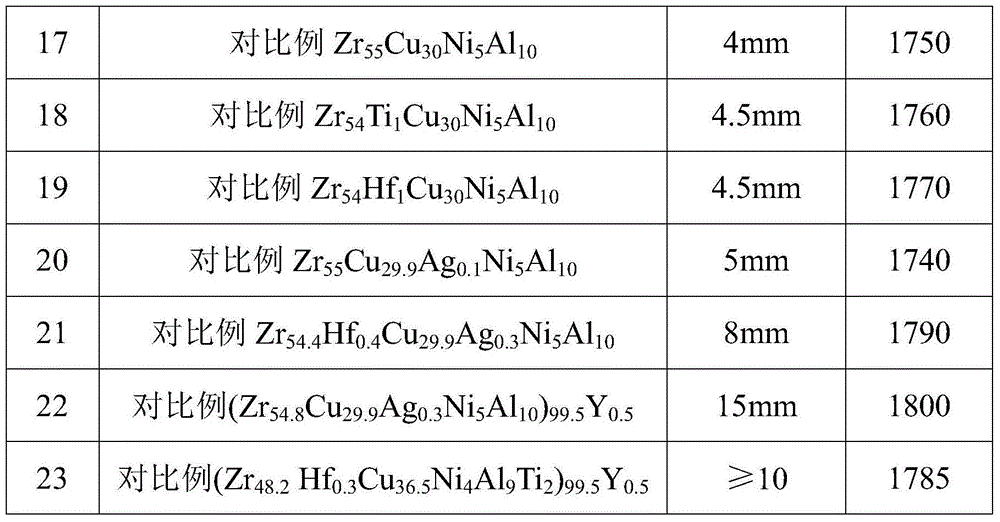

Examples

Embodiment 18

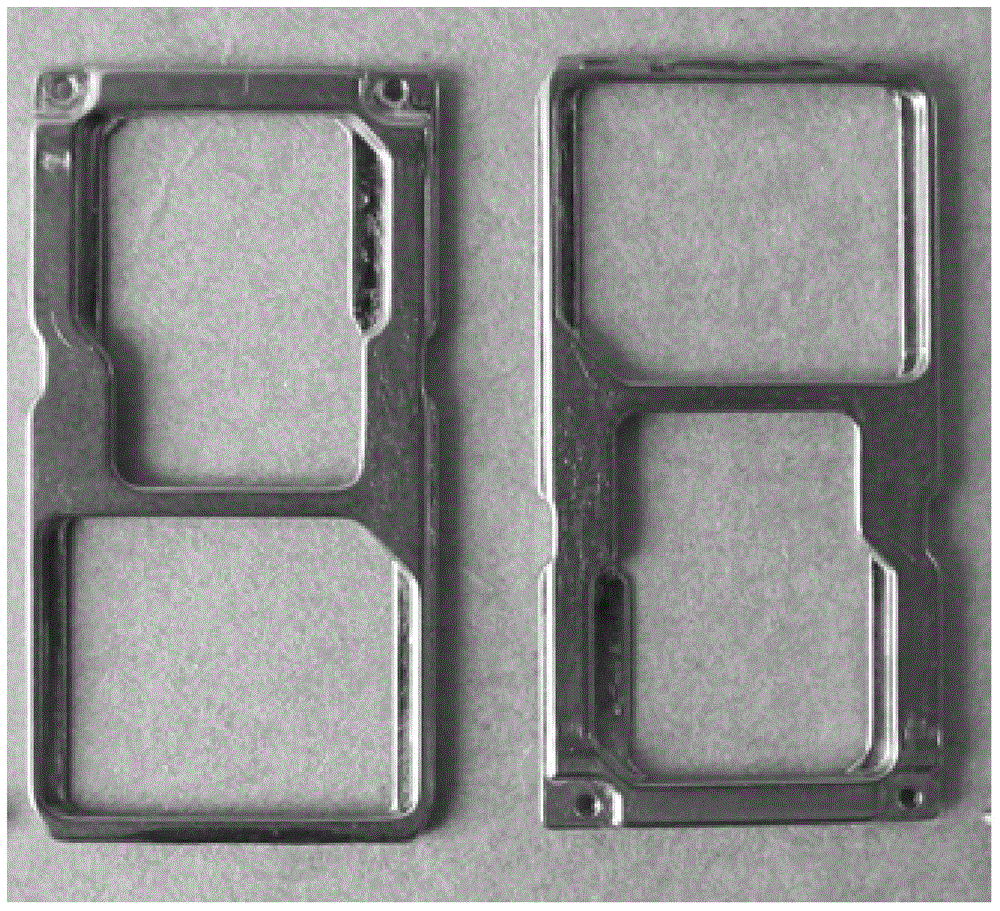

[0027] Use (Zr 54.4 f 0.4 Cu 29.9 Ag 0.3 Ni 5 Al 10 ) 99.5 Y 0.5 Alloy, induction melting 30kg, vacuum degree 10 -1 ~10 -2 Pa. Preparation of amorphous components by vacuum die-casting, heating temperature 900-1000°C, vacuum degree 10-10 -1 Pa, the alloy is reused 5 times, and the prepared components can still ensure the amorphous structure of the material. The prepared parts such as figure 1 shown. Repeatedly using the alloy four times to cast the φ5mm sample can ensure the formation of amorphous.

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com