Fe-Ai-Al powder core annular magnet and preparation method thereof

A ring magnet, fe-si-al technology, applied in the direction of magnetic objects, inductance/transformer/magnet manufacturing, magnetic materials, etc., can solve the problem of high loss, achieve the effect of low pressing pressure, simple manufacturing process, and short holding time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

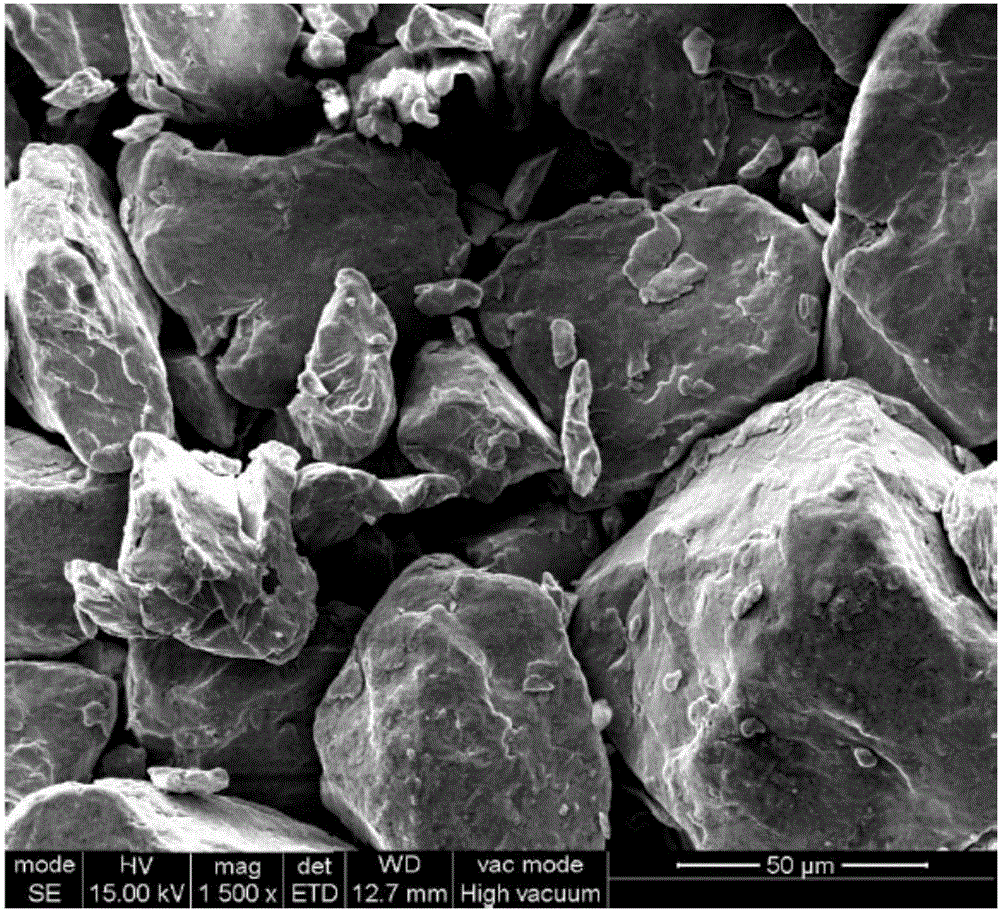

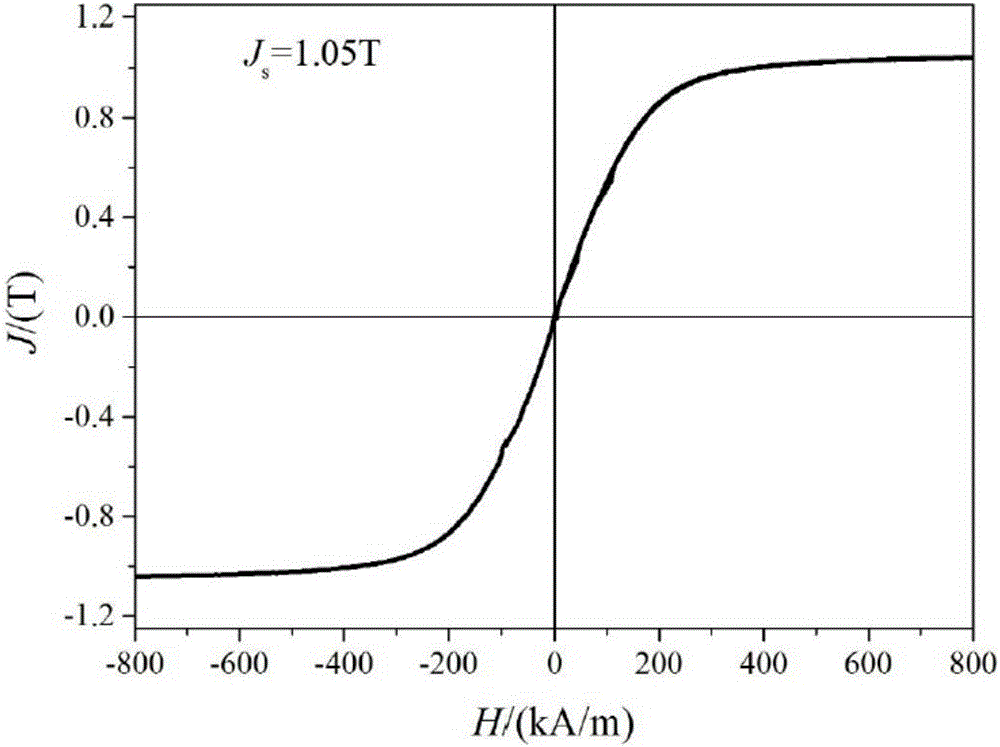

[0035] Step 1: SEM test the original Fe-Si-Al alloy powder (see figure 1 ) And VSM hysteresis loop test (see figure 2 ).

[0036] Step 2: Pour the original Fe-Si-Al alloy powder into an acetone solution containing a coupling agent (silane coupling agent KH-550) and stir evenly, wherein the mass of the coupling agent accounts for 0.5% of the total mass of the magnetic powder. Then place it in a vacuum drying oven for drying.

[0037] Step 3: Add 7wt% insulating binder to the dried powder, the composition of which is silicone resin, kaolin and α-Al 2 O 3 , Of which kaolin and α-Al 2 O 3 It belongs to the addition of inorganic substances, and it is dried again after stirring. Wherein m (silicone resin): m (nano alumina and kaolin) = 2:1, m (nano alumina): m (kaolin) = 1:1.

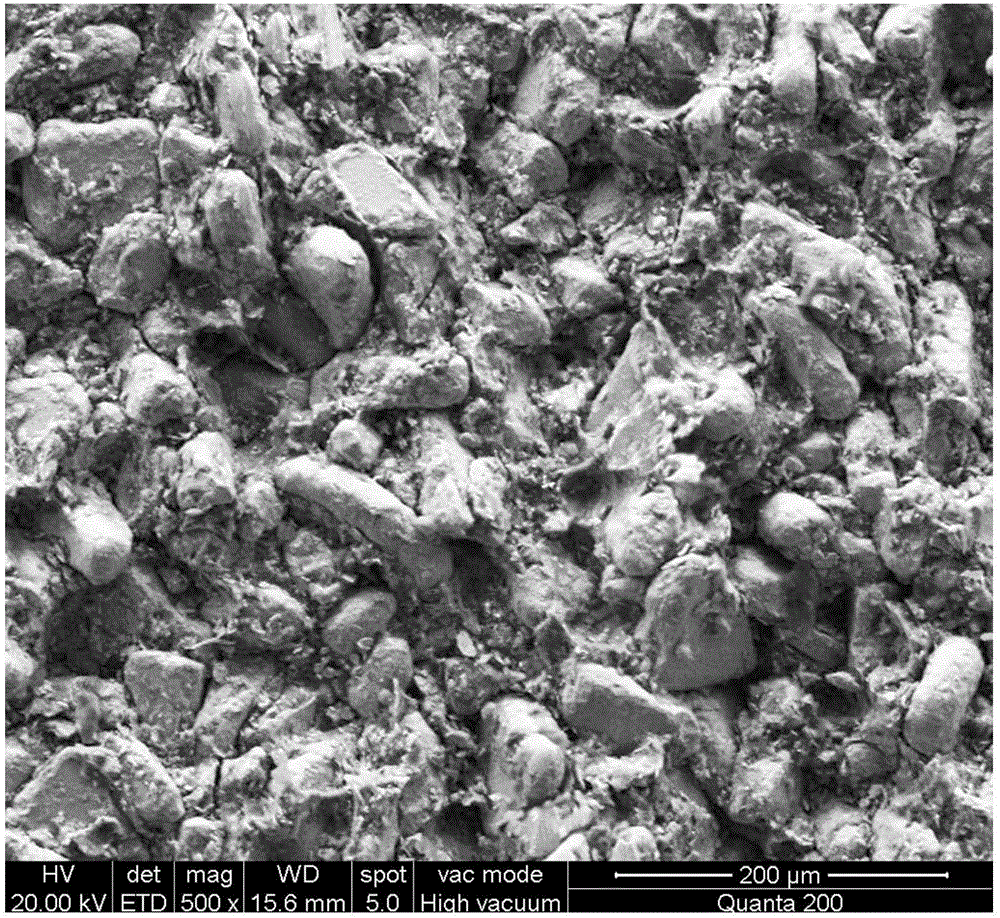

[0038] Step 4: Press the configured mixed powder under a pressure of 1600Mpa to form a magnetic ring with an outer diameter of 20mm, an inner diameter of 12mm, and a height of about 4.5mm. The microstructure morp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com