High-saturation magnetic induction density iron cobalt-based nanocrystal soft magnetic powder core and preparation method thereof

A nanocrystalline soft magnetic and magnetic induction technology, applied in the manufacture of inductors/transformers/magnets, magnetic materials, magnetic objects, etc., can solve the problems of application limitations, high cost of iron-nickel-molybdenum magnetic powder cores, etc., and achieve excellent soft magnetic performance, Easy to form, simple process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

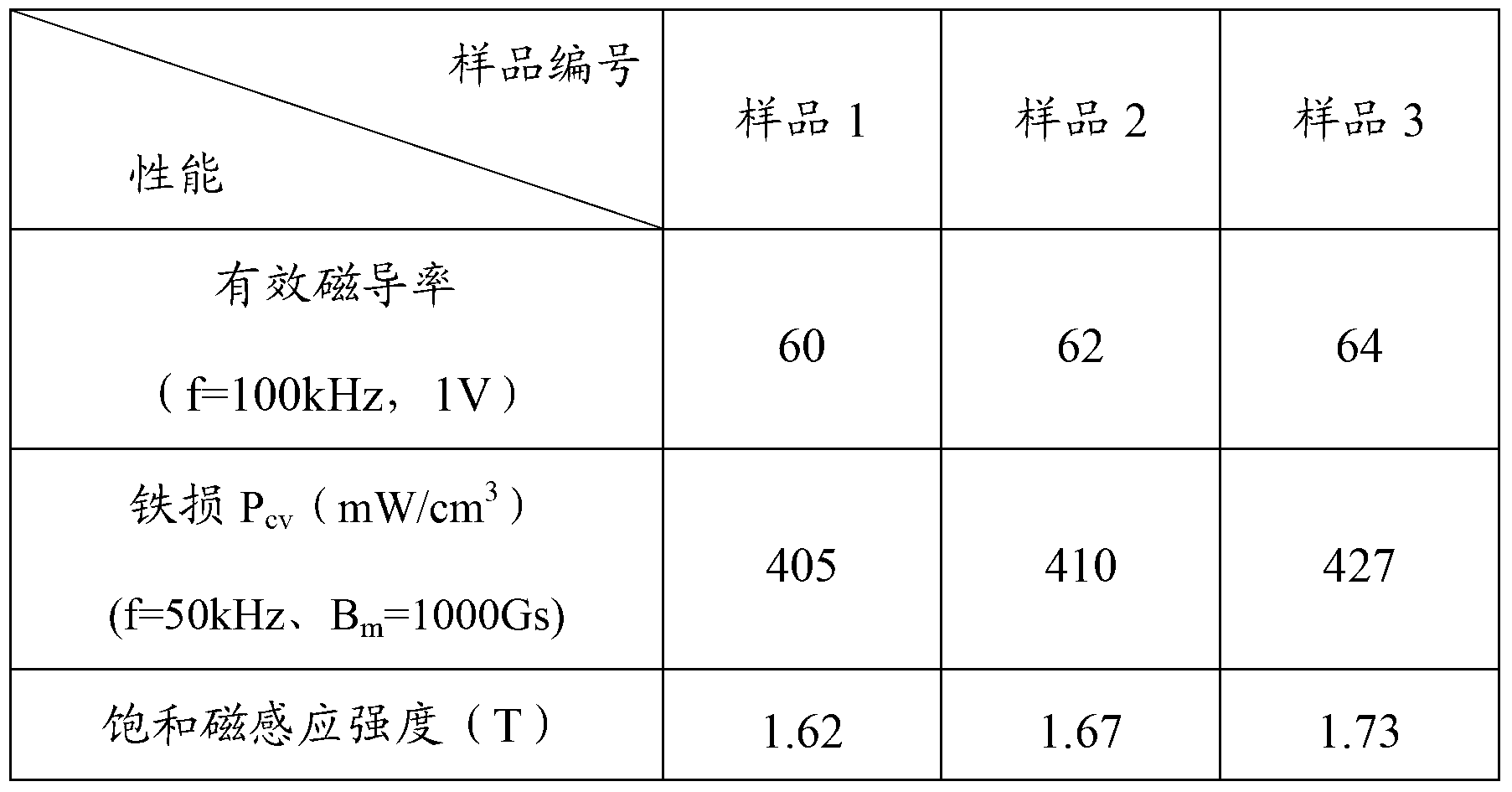

Embodiment 1

[0016] (1) Fe 5 co 82 Si 3 B 4 Cu 0.4 C 5.6 After the amorphous strip is kept at 420°C for 1 hour in a vacuum annealing furnace, it is mechanically crushed;

[0017] (2) Fe 5 co 82 Si 3 B 4 Cu 0.4 C 5.6 After the amorphous ribbon is mechanically crushed, it is placed in a planetary ball mill for ball milling, the ball-to-material ratio is 10:1, the ball milling time is 8 hours, the speed is 260r / min, and ethanol is added to prevent oxidation. After drying, it is screened to obtain different particle sizes. Fe 5 co 82 Si 3 B 4 Cu 0.4 C 5.6 magnetic powder;

[0018] (3) Different meshes of Fe 5 co 82 Si 3 B 4 Cu 0.4 C 5.6 Magnetic powder is mixed, of which -100 mesh ~ +200 mesh Fe 5 co 82 Si 3 B 4 Cu 0.4 C 5.6 Magnetic powder accounts for 15% of the total mass, -200 mesh to +300 mesh Fe 5 co 82 Si 3 B 4 Cu 0.4 C 5.6 Magnetic powder accounts for 70% of the total mass, -300 mesh to +400 mesh Fe 5 co 82 Si 3 B 4 Cu 0.4 C 5.6 Magnetic powder ...

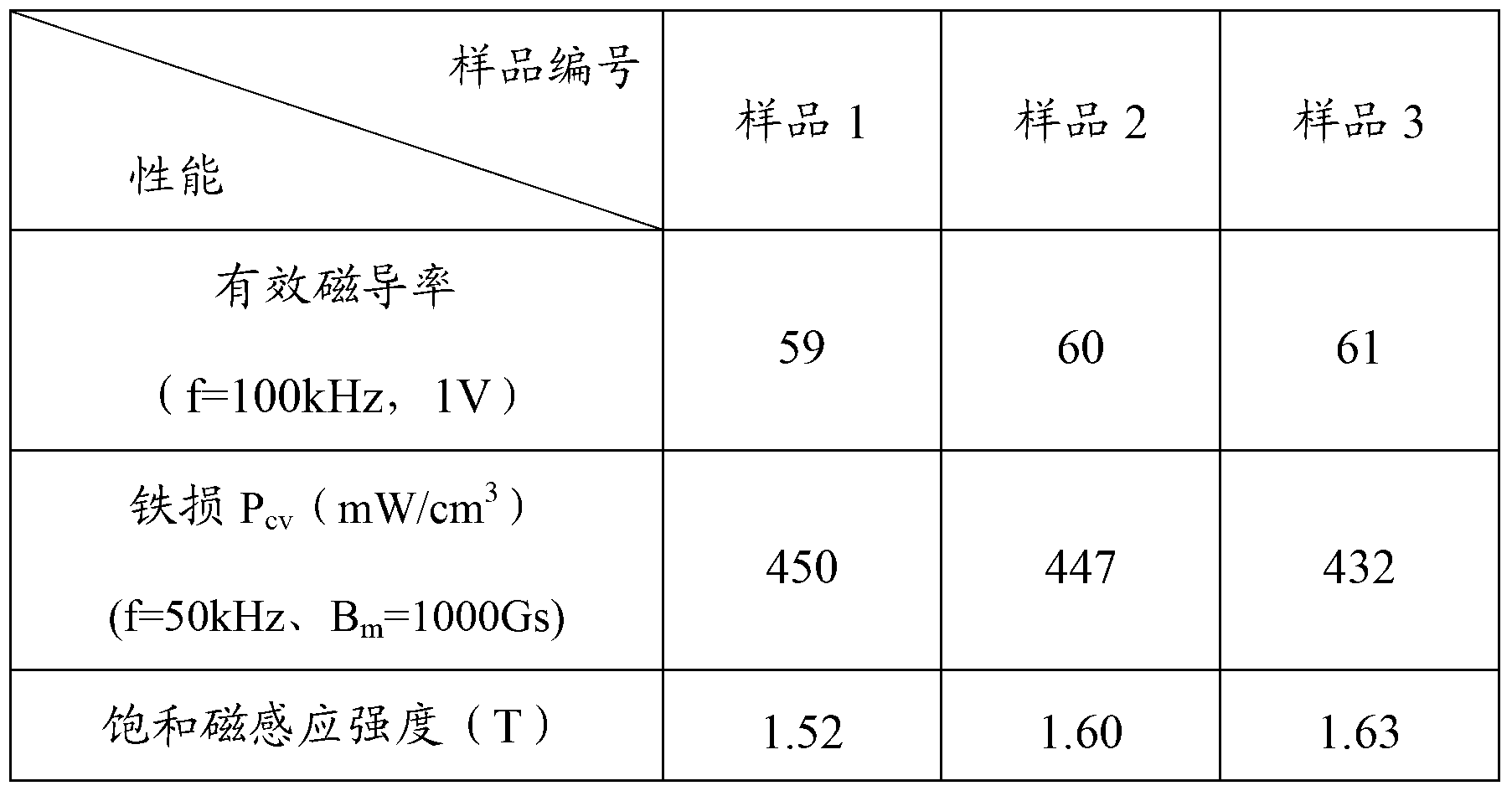

Embodiment 2

[0023] (1) Fe 82 co 5 Si 3 B 4 Cu 1.5 P 4.5 After the amorphous strip is kept at 420°C for 1 hour in a vacuum annealing furnace, it is mechanically crushed;

[0024] (2) Fe 82 co 5 Si 3 B 4 Cu 1.5 P 4.5 After the amorphous ribbon is mechanically crushed, it is placed in a planetary ball mill for ball milling, the ball-to-material ratio is 10:1, the ball milling time is 8 hours, the speed is 260r / min, and ethanol is added to prevent oxidation. After drying, it is screened to obtain different particle sizes. Fe 82 co 5 Si 3 B 4 Cu1.5 P 4.5 magnetic powder;

[0025] (3) Different meshes of Fe 82 co 5 Si 3 B 4 Cu 1.5 P 4.5 Magnetic powder is mixed, of which -100 mesh ~ +200 mesh Fe 82 co 5 Si 3 B 4 Cu 1.5 P 4.5 Magnetic powder accounts for 15% of the total mass, -200 mesh to +300 mesh Fe 82 co 5 Si 3 B 4 Cu 1.5 P 4.5 Magnetic powder accounts for 70% of the total mass, -300 mesh to +400 mesh Fe 82 co 5 Si 3 B 4 Cu 1.5 P 4.5 Magnetic powder ac...

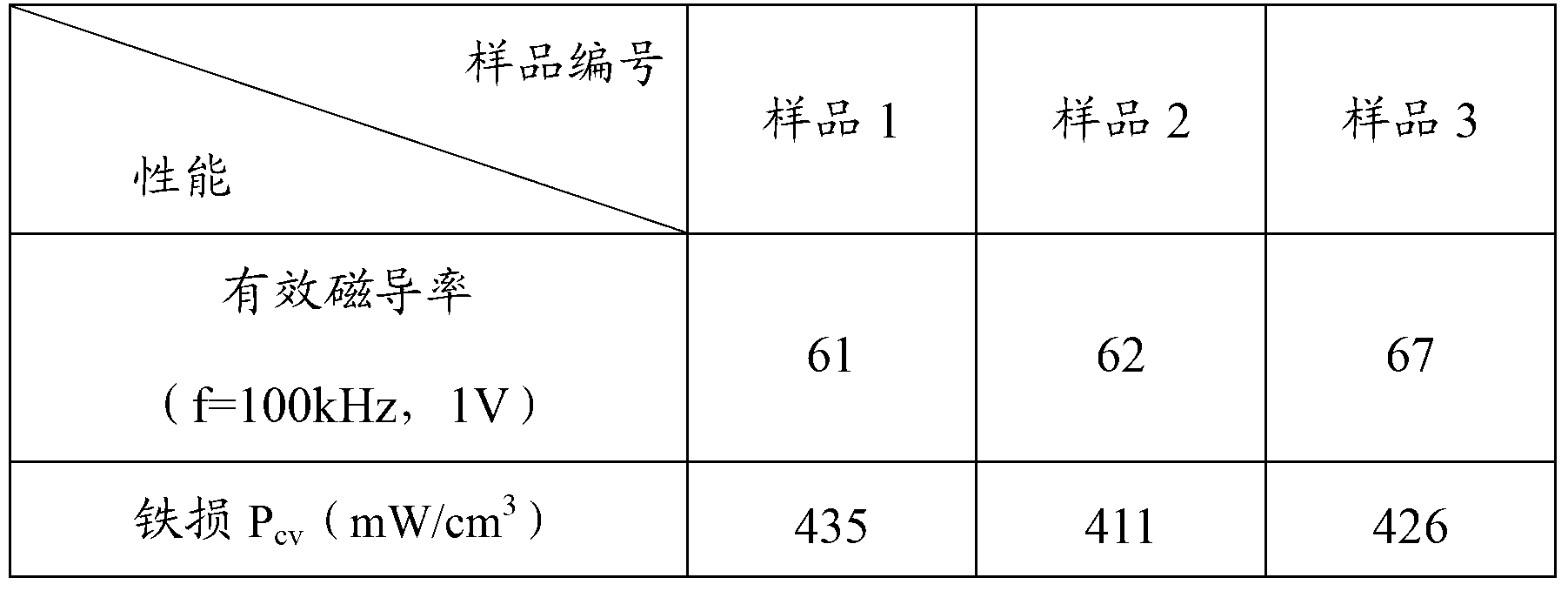

Embodiment 3

[0030] (1) Fe 50 co 12.5 Si 15 B 13 Cu 1.5 Cr 8 After the amorphous strip is kept at 420°C for 1 hour in a vacuum annealing furnace, it is mechanically crushed;

[0031] (2) Fe 50 co 12.5 Si 15 B 13 Cu 1.5 Cr 8 After the amorphous ribbon is mechanically crushed, it is placed in a planetary ball mill for ball milling, the ball-to-material ratio is 10:1, the ball milling time is 8 hours, the speed is 260r / min, and ethanol is added to prevent oxidation. After drying, it is screened to obtain different particle sizes. Fe 50 co 12.5 Si 15 B 13 Cu 1.5 Cr 8 magnetic powder;

[0032] (3) Different meshes of Fe 50 co 12.5 Si 15 B 13 Cu 1.5 Cr 8 Magnetic powder is mixed, of which -100 mesh ~ +200 mesh Fe 50 co 12.5 Si 15 B 13 Cu 1.5 Cr 8 Magnetic powder accounts for 15% of the total mass, -200 mesh to +300 mesh Fe 50 co 12.5 Si 15 B 13 Cu 1.5 Cr 8 Magnetic powder accounts for 70% of the total mass, -300 mesh to +400 mesh Fe 50 co 12.5 Si 15 B 13 Cu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com