Amorphous-nanocrystalline composite magnetic power core and production method thereof

An amorphous nanocrystalline, magnetic powder core technology, applied in the direction of inductor/transformer/magnet manufacturing, magnetic materials, magnetic objects, etc., can solve the problem of low saturation magnetic induction intensity and permeability, low magnetic particle content, DC magnetic flux density Low problems, to achieve the effect of improving magnetic properties and mechanical properties, excellent soft magnetic properties, and ensuring insulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

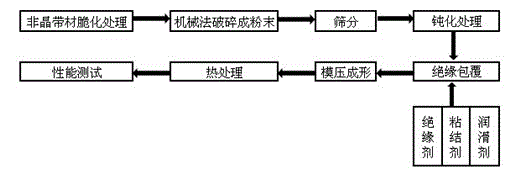

Method used

Image

Examples

Embodiment 1

[0034] The amorphous nanocrystalline composite magnetic powder core provided in this embodiment is mainly composed of iron-based amorphous powder, iron-based nanocrystalline powder, organic binder and insulating agent. 0.5~2wt% and 0.5~4wt% of the total weight; and the insulating agent is a mixture of inorganic oxides, carbides and nitrides. The inorganic oxide is selected from SiO 2、 Al 2 o 3、 TiO 2、 ZrO 2One or more; the carbide is selected from one or both of AlC and TiC; the nitride is selected from one or both of AlN and TiN. The insulating agents are all nano powders.

[0035] The iron-based amorphous powder is made of amorphous Fe that passes through -200~+270 mesh 80 Si 12.6 B 5.4 C 2 Powder, the iron-based nanocrystalline powder adopts nanocrystalline Fe passing through -270~+325 mesh 73.5 Cu 1 Nb 3 Si 13.5 B 9 Powder, organic binder adopts phenolic resin.

[0036] Specifically, iron-based amorphous Fe a (Si b B 1-b ) 98-a C 2 In the powder, a is 8...

Embodiment 2

[0060] The amorphous nanocrystalline composite magnetic powder core provided in this embodiment is mainly composed of iron-based amorphous powder, iron-based nanocrystalline powder, organic binder and insulating agent, and the weight of organic binder and insulating agent accounts for two powders respectively 1wt% and 2wt% of the total weight.

[0061] The iron-based amorphous powder is made of amorphous Fe that passes through -200~+270 mesh 80 Si 12.6 B 5.4 C 2 Powder, the iron-based nanocrystalline powder adopts nanocrystalline Fe passing through -270~+325 mesh 73.5 Cu 1 Nb 3 Si 13.5 B 9 Powder, organic binder adopts epoxy resin, insulating agent adopts ZrO 2 , AlC, TiN mixture, the weight ratio of the three is 5:4:1.

[0062] The weight content of the iron-based amorphous powder in the two powders is 15-60wt%, and that of the iron-based nanocrystalline powder is 40-85wt%.

[0063] Specifically, iron-based amorphous Fe a (Si b B 1-b ) 98-a C 2 In the powder, a...

Embodiment 3

[0074] The difference between the amorphous nanocrystalline composite magnetic powder core provided in this example and Example 1 is that the iron-based amorphous powder uses Fe 80 Si 7.2 B 10.8 C 2 powder. Specifically, iron-based amorphous Fe a (Si b B 1-b ) 98-a C 2 In the powder, a is 80, and b is 0.4.

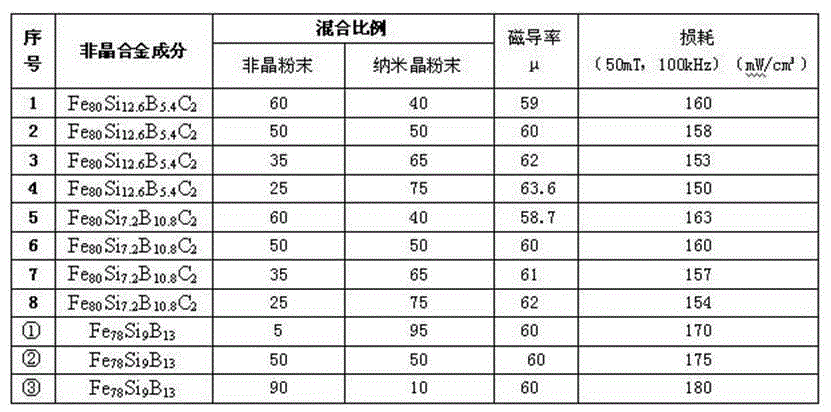

[0075] In this embodiment, the proportions of the two powders were changed to obtain 4 examples, marked as 5-8. The contents of iron-based amorphous powder and iron-based nanocrystalline powder in each example are as described in Table 2.

[0076] The preparation method of the above-mentioned amorphous nanocrystalline composite magnetic powder core provided in this embodiment differs from that of Example 2 in that the iron-based amorphous strip is made of Fe 80 Si 7.2 B 10.8 C 2 Made of iron-based amorphous powder.

[0077] Performance test: Detect the magnetic performance of the magnetic core and record it in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com