Method for preparing high silicon thin steel strip through single-roller melt spinning method

A technology of single-roll stripping and high-silicon steel, which is applied in the field of silicon steel sheet production, can solve problems such as long processing cycle, equipment corrosion, and narrow width of high-silicon steel thin strips, so as to improve the quality of sprayed strips, prevent oxidation of molten steel, and wide bandwidth range Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

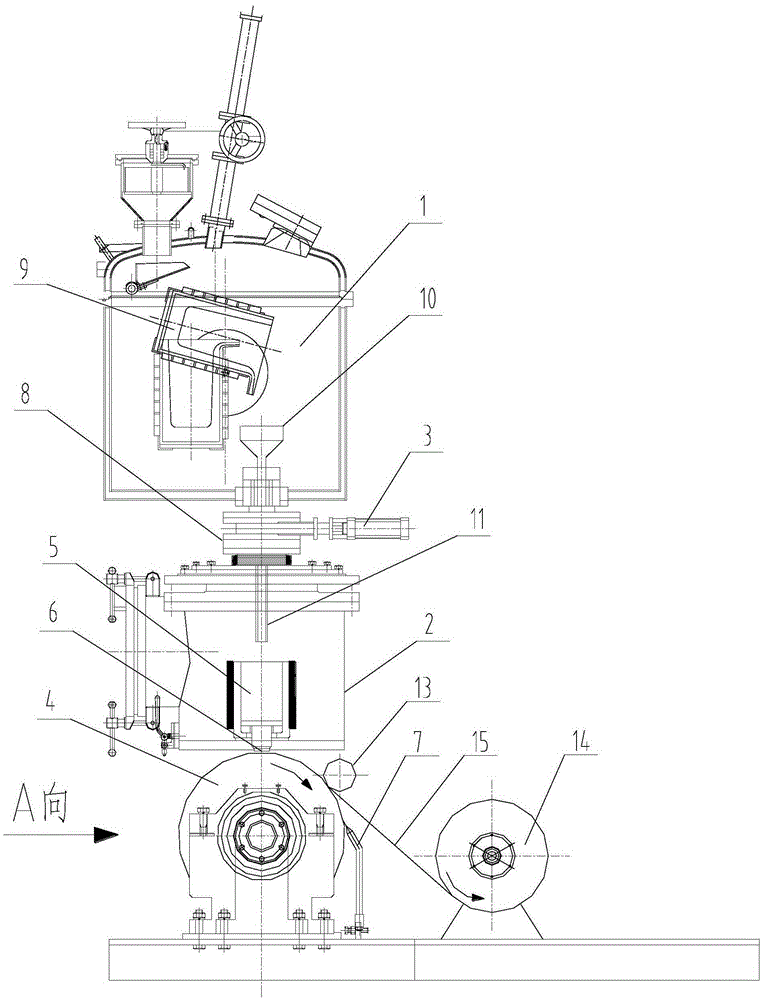

[0045] 1) Put the high-silicon steel master alloy with a silicon content of 6.5% into the vacuum furnace 1, add B, Mn, Al, and Ni to improve the formability of the high-silicon steel, and the mass contents of the single components of B, Mn, and Al added are respectively 2.9%, 0.02%, 0.01%, vacuum smelting to obtain molten steel, the smelting temperature is about 1580°C, the absolute vacuum degree of smelting is 5Pa; the preheating insulation bag is 2 to 1500°C;

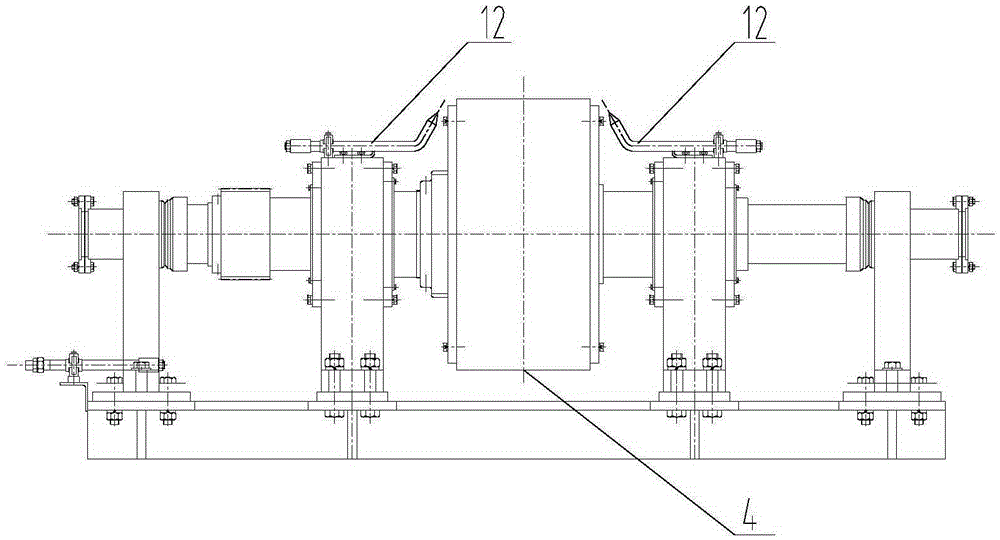

[0046] 2) After the smelting is completed, slowly pass the protective gas Ar into the vacuum furnace 1 and the insulation bag 2 to 0.1MPa. When the air pressure in the vacuum furnace 1 is the same as that in the insulation bag 2, open the plug valve 3 between the two , the insulation bag 2 is lowered to the working position above the crystallization roller 4 as a whole; the jet pipe 12 and the gas stripping device 7 of the crystallization roller 4, the molten pool protection gas are opened, and the stable rotating spee...

Embodiment 2

[0053] 1) Put a high-silicon steel master alloy with a silicon content of 6.5% into the vacuum furnace 1, add about 2.5% of B, about 0.1% of Mn, and about 0.1% of Ni;

[0054] Carry out vacuum smelting to obtain molten steel, the smelting temperature is about 1530°C, and the absolute vacuum degree of smelting is 0.8Pa; preheat the insulation bag at 2 to 1500°C;

[0055] 2) After the smelting is completed, slowly pass the protective gas Ar into the vacuum furnace 1 and the insulation bag 2 to 0.12MPa. When the air pressure in the vacuum furnace 1 is the same as that in the insulation bag 2, open the plug valve 3 between the two , lower the thermal insulation bag 2 to the working position above the crystallization roller 4; open the crystallization roller 4, the jet pipe 12 of the molten pool protection gas and the gas stripping device 7, adjust the stable speed of the crystallization roller 4 to be 30m / s, and the molten pool protection Gas pressure 0.3MPa.

[0056] 3) Pour the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| saturation magnetic induction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com