Preparation method of CuCr alloy powder with low chromium content

A technology of alloy powder and chromium content, applied in the field of preparation of CuCr alloy powder, can solve the problems of introducing impurities, etc., and achieve the effects of easy powder sintering, refinement of solidified structure, and reduction of Cr phase composition segregation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0023] The invention provides a method for preparing CuCr alloy powder with low chromium content. The CuCr alloy powder is prepared by gas atomization technology. The method is implemented according to the following steps:

[0024] Step 1, raw material weighing

[0025] Weighing 99-95% of the Cu block and 1-5% of the Cr particles according to the mass percentage, the sum of the mass percentages of Cu and Cr is 100%, and the particle size of the Cr particles is 1-4mm;

[0026] Step 2, Smelting

[0027] First bake the medium frequency induction furnace, then put the Cu block weighed in step 1 into the graphite crucible, and put them into the induction furnace together, adjust the power of the induction furnace to 200-240KW, the frequency to 1000-1200Hz, and quickly heat up to The melting point of Cu is to melt the Cu block, and then add the Cr particles weighed in step 1, and then add the slagging agent and covering agent in sequence. The slagging agent is potassium fluozircon...

Embodiment 1

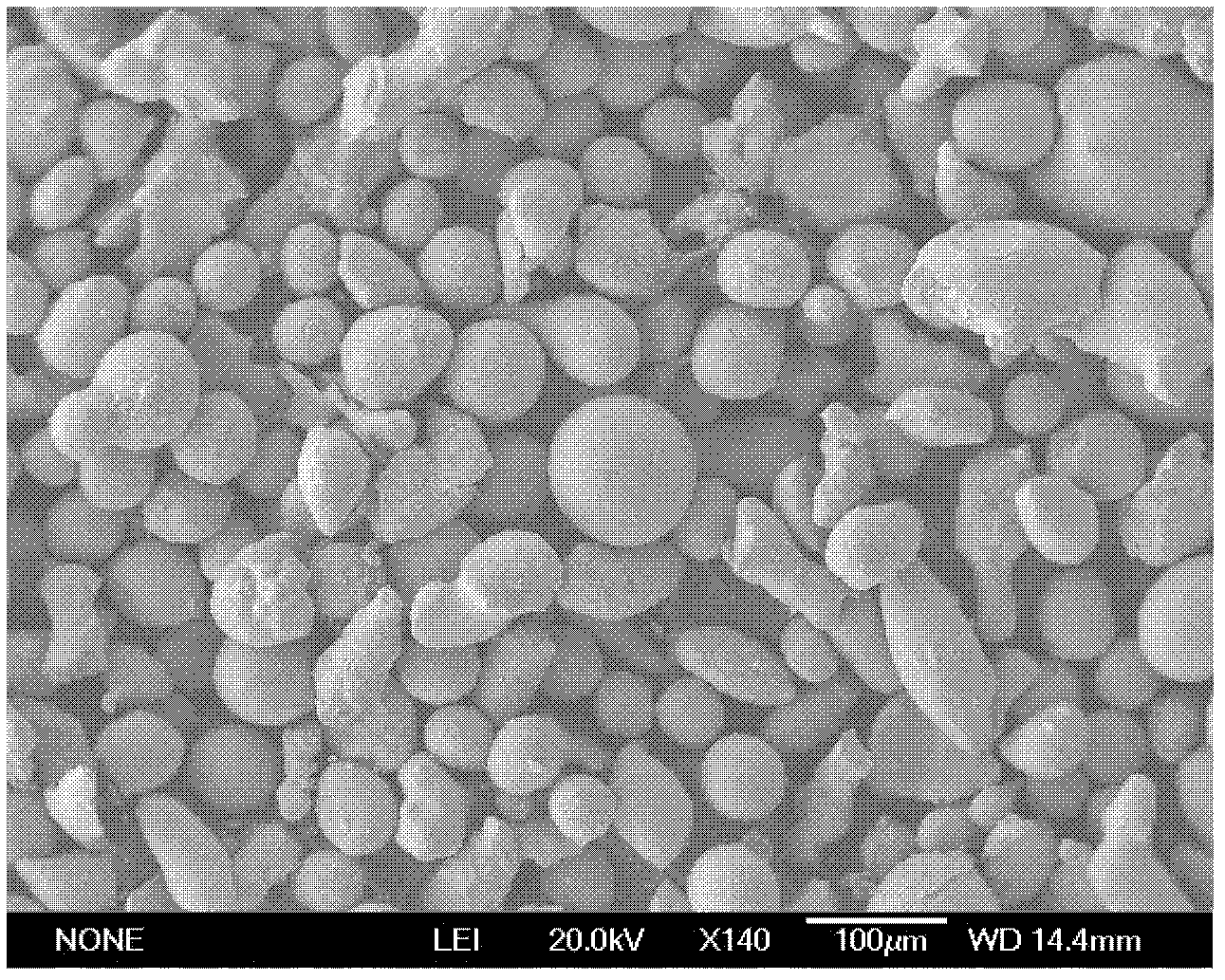

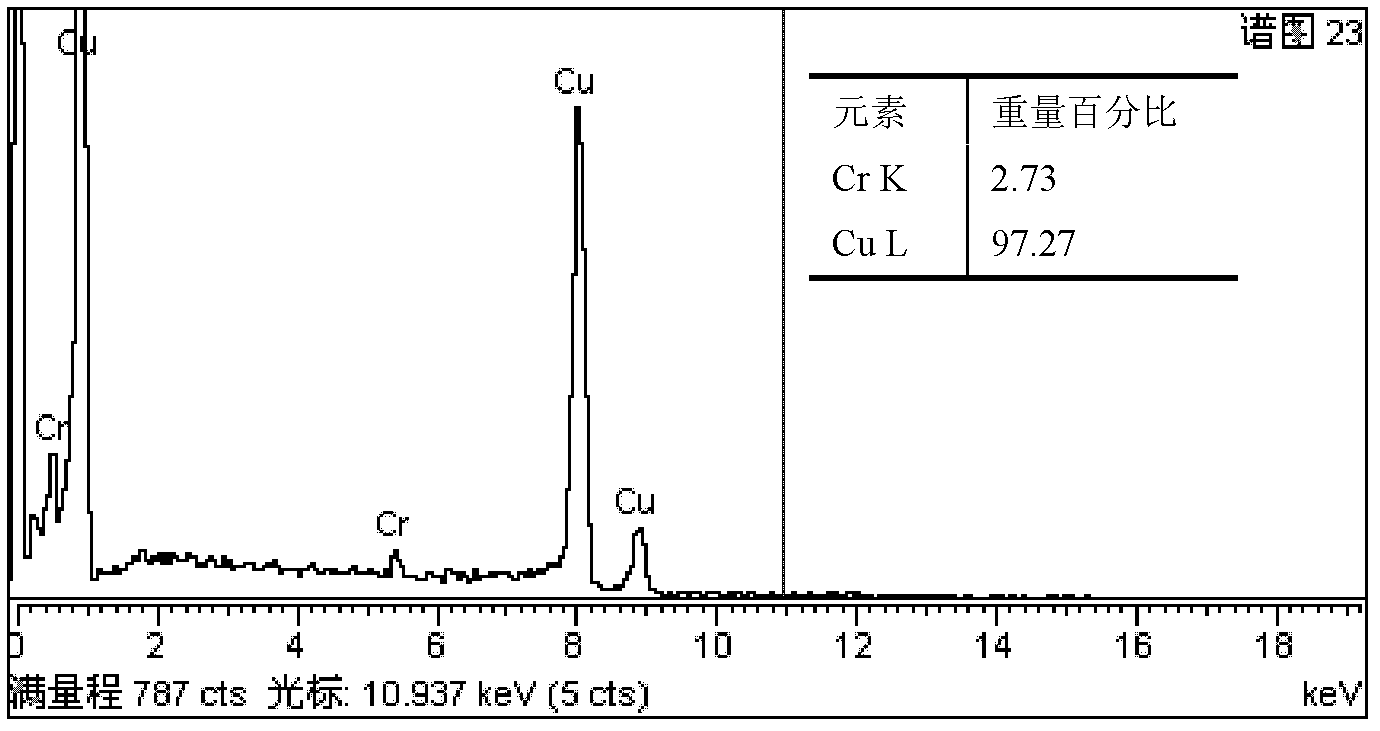

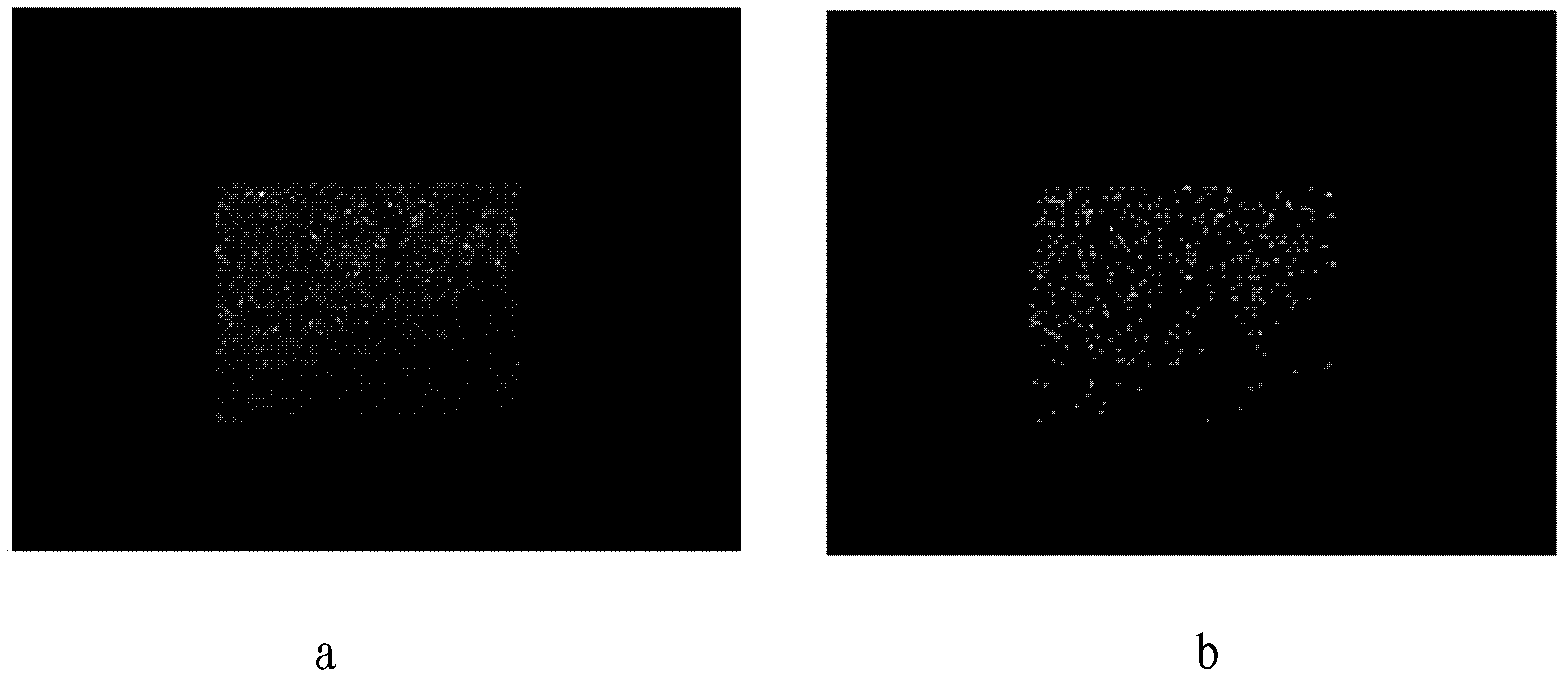

[0031] Take by weighing 97% of the Cu blocks and 3% of the Cr particles according to the mass percentage, and the particle size of the Cr particles is 1 to 4mm; the Cu blocks are packed in a graphite crucible, and put into the induction furnace together, and the power of the induction furnace is adjusted to 240KW, The frequency is 1100Hz, and the temperature is rapidly raised to the melting point of Cu to melt the Cu block, then the weighed Cr particles are added, and then the slagging agent and the covering agent are added in sequence. The slagging agent is potassium fluozirconate, and the addition amount is 1% of the mass of Cu; the covering agent is charcoal, and the charcoal must completely cover the surface of the melt, and the covering thickness is 4mm. Continue to heat up the medium-frequency induction furnace until the melt temperature reaches 1300°C, and keep it warm for 5 minutes. After Cu and Cr are fully mixed, remove the slag on the surface of the melt, and open th...

Embodiment 2

[0033] Take by weighing 99% of the Cu blocks and 1% of the Cr particles according to the mass percentage, and the particle size of the Cr particles is 1 to 4mm; the Cu blocks are packed in a graphite crucible, and put into the induction furnace together, and the power of the induction furnace is adjusted to 230KW, The frequency is 1000Hz, and the temperature is rapidly raised to the melting point of Cu to melt the Cu block, and then the weighed Cr particles are added, and then the slagging agent and the covering agent are added in sequence. The slagging agent is potassium fluozirconate, and the addition amount is 2% of the mass of Cu; the covering agent is charcoal, and the charcoal must completely cover the surface of the melt, and the covering thickness is 6mm. Continue to heat up the medium-frequency induction furnace until the melt temperature reaches 1200 ° C, and keep it warm for 8 minutes. After Cu and Cr are fully mixed, remove the slag on the surface of the melt, open ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com