Preparation method of superfine grain nano-structure oxide dispersion strengthened steel

A nano-structure and dispersion strengthening technology is used in the preparation of radiation-resistant alloys, the core components of nuclear reactors are used in the fields of high temperature resistance and high strength, which can solve the problems of structural and performance anisotropy, long time, coarse grains, etc. The effect of shortening time, suppressing growth, and lowering sintering temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

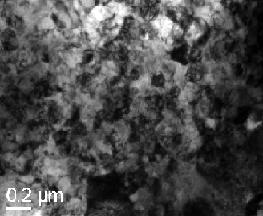

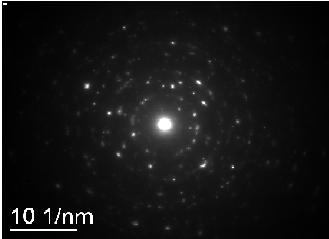

[0017] Using high-purity metal element powder, each component is 9.0% by mass percentage Cr, W is 1.0%, Mn is 0.4%, V is 0.4%, Ta is 0.4%, and the balance is Fe, and the mass percentage is 0.3%. Ti powder, 0.3% Y 2 o 3 Powders are mixed and milled by high energy ball to form Y 2 o 3 Supersaturated alloy powder with complete solid solution with Ti, the particle size of the powder is on the order of microns, and the grain size is on the order of tens of nanometers. After discharge plasma sintering in a vacuum environment, the sintering temperature is 1000°C, the sintering time is 3min, and the sintering pressure is 40MPa. After solidification and molding, the crystal structure of the alloy is martensite, and the density is 98.1% of the theoretical density. The strength is 1204MPa, and the size of most grains is between 100 and 300 nanometers, see figure 1 , figure 2 shown.

Embodiment 2

[0019] Using high-purity metal element powder, each component is 16.0% by mass percentage Cr, 4.0% W, and the balance is Fe, and the mass percentage is 3% Ti powder, 3% Y 2 o 3 The powder is mixed and milled by high energy ball to form Y 2 o 3 Supersaturated alloy powder with complete solid solution with Ti, the particle size of the powder is on the order of microns, and the grain size is on the order of tens of nanometers. After discharge plasma sintering in an Ar gas environment, the sintering temperature is 800°C, the sintering time is 15min, and the sintering pressure is 200MPa. After solidification, the crystal structure of the alloy is ferrite, the density reaches 98.2% of the theoretical density, and the tensile strength at room temperature reaches 1158MPa. . The size of most of the grains is between 150-350nm.

Embodiment 3

[0021] Using atomized alloy powder, each component of the alloy is 12.0% by mass percentage Cr, 2.0% W, 1.0% Mn, 1.0% V, 1.0% Ta, the balance is Fe, and 0.1% Ti by mass percentage , 0.1% of Y 2 o 3 Mixed and high energy ball milled to form Y 2 o 3 Supersaturated alloy powder with complete solid solution with Ti, the particle size of the powder is on the order of microns, and the grain size is on the order of tens of nanometers. After discharge plasma sintering in an Ar gas environment, the sintering temperature is 1200°C, the sintering time is 1min, and the sintering pressure is 10MPa. After solidification, the crystal structure of the alloy is a ferrite / martensite dual-phase structure, and the density reaches 98.0% of the theoretical density. , The tensile strength at room temperature reaches 1047MPa. The size of most grains is between 200 and 500 nanometers.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Scale | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com