Preparation method of mechanical alloying copper-tungsten alloy powder

A mechanical alloying, copper-tungsten alloy technology, applied in the field of metal alloy materials, can solve the problems of poor flow performance of copper-tungsten alloy powder, poor uniformity of composition distribution, environmental pollution, etc., and achieve good flow performance, large powder particles, The effect of uniform composition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

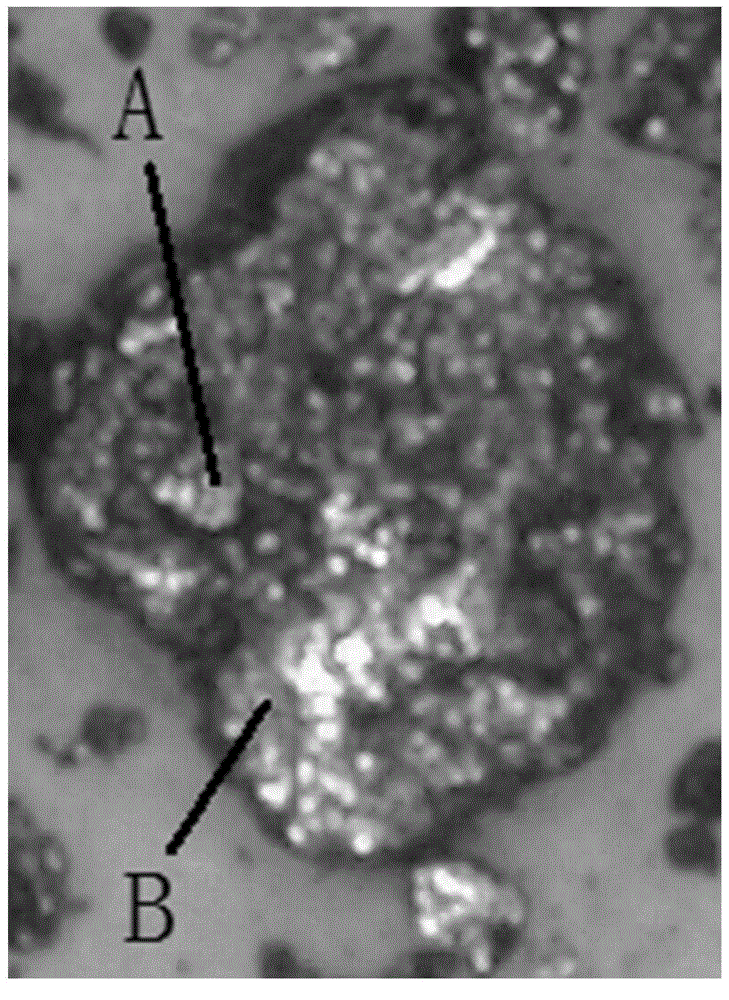

Image

Examples

Embodiment 1

[0031] 1) Prepare tungsten powder and copper powder in proportion to make copper-tungsten composite powder, and put them into a high-energy stirring mill; in the tungsten-copper composite powder, the copper powder is atomized copper powder of 100 mesh to 300 mesh, accounting for 80wt%. The rest is tungsten powder, crystalline tungsten powder of -320 mesh;

[0032] 2) In the stirring mill, add ball milling medium and grinding balls, wherein the ball milling medium is a volatile organic solvent, accounting for 0.5% of the mass of the copper-tungsten composite powder; The mass ratio is 60:1;

[0033] 3) Fill the stirring mill with nitrogen, the stirring mill has its own circulating cooling water, the ball milling time is 2 hours at room temperature, and the ball milling speed is 500r / min;

[0034] 4) After ball milling, put it into a stabilization container, fill it with nitrogen, and cool it down for 30 minutes;

[0035] 5) After cooling, pass through the steel belt furnace, t...

Embodiment 2

[0041] 1) Prepare tungsten powder and copper powder in proportion to make copper-tungsten composite powder, and put them into a high-energy stirring mill; in the tungsten-copper composite powder, the copper powder is atomized copper powder of 100 mesh to 300 mesh, accounting for 60wt%. The rest is tungsten powder, crystalline tungsten powder of -320 mesh;

[0042] 2) In the stirring mill, add ball milling media and balls, wherein the ball milling media is a volatile organic solvent, accounting for 1% of the mass of the copper-tungsten composite powder; the balls are cemented carbide balls, and the balls are compounded with copper-tungsten The mass ratio of powder is 40:1;

[0043] 3) Fill the stirring mill with nitrogen, the stirring mill has its own circulating cooling water, the ball milling time is 3 hours at room temperature, and the ball milling speed is 400r / min;

[0044] 4) After ball milling, put it into a stabilization container, fill it with nitrogen, and cool it do...

Embodiment 3

[0051] 1) Prepare tungsten powder and copper powder in proportion to make copper-tungsten composite powder, and put them into a high-energy stirring mill; in the tungsten-copper composite powder, the copper powder is atomized copper powder of 100 mesh to 300 mesh, accounting for 40wt%. The rest is tungsten powder, crystalline tungsten powder of -320 mesh;

[0052] 2) In the stirring mill, add ball milling medium and grinding balls, wherein the ball milling medium is a volatile organic solvent, accounting for 2% of the mass of the copper-tungsten composite powder; The mass ratio is 20:1;

[0053] 3) Fill the stirring mill with nitrogen, the stirring mill has its own circulating cooling water, the ball milling time is 5 hours at room temperature, and the ball milling speed is 300r / min;

[0054]4) After ball milling, put it into a stabilization container, fill it with nitrogen, and cool it down for 30 minutes;

[0055] 5) After cooling, pass through the steel belt furnace, the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mesh | aaaaa | aaaaa |

| Mesh | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com