Method and device for measuring continuous cooling phase transformation points of aluminum alloy

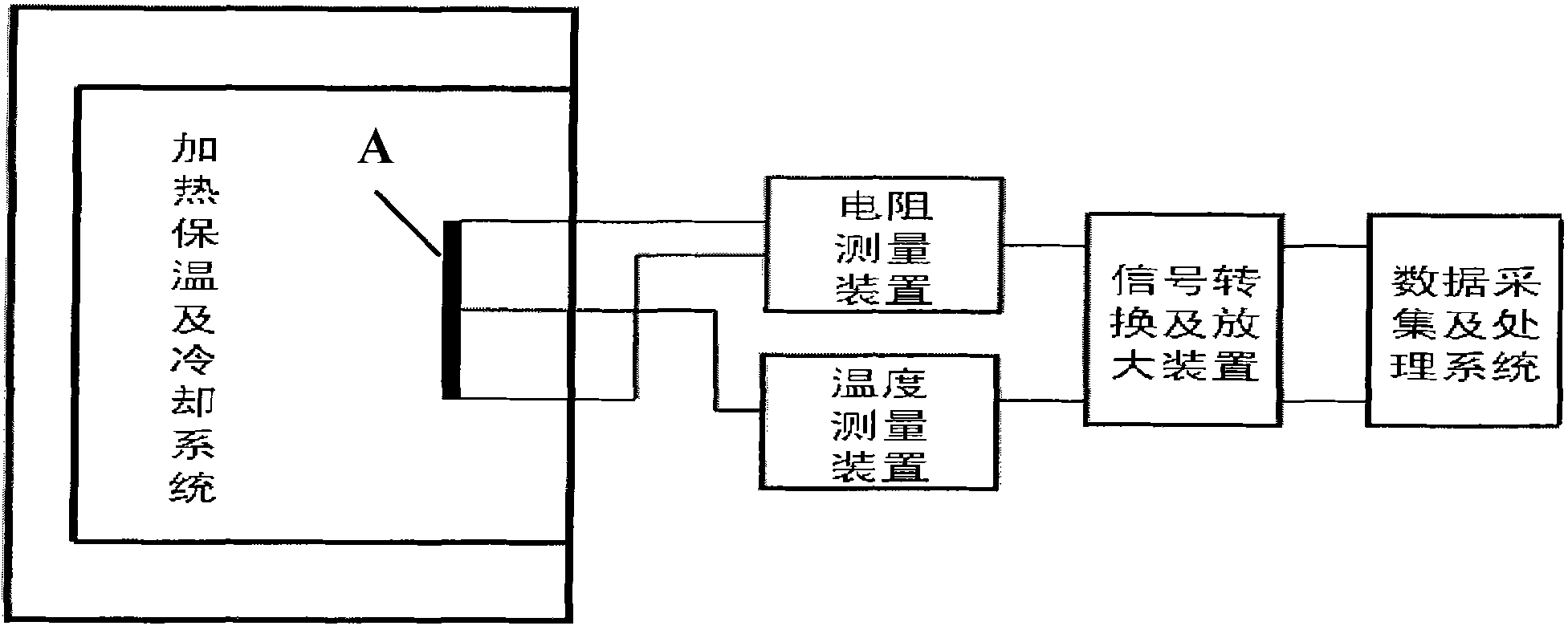

A technology of aluminum alloy and transformation point, applied in the investigation stage/state change and other directions, can solve the problem of difficult measurement of transformation point of aluminum alloy, and achieve the effect of rich functions, convenient operation and large cooling rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

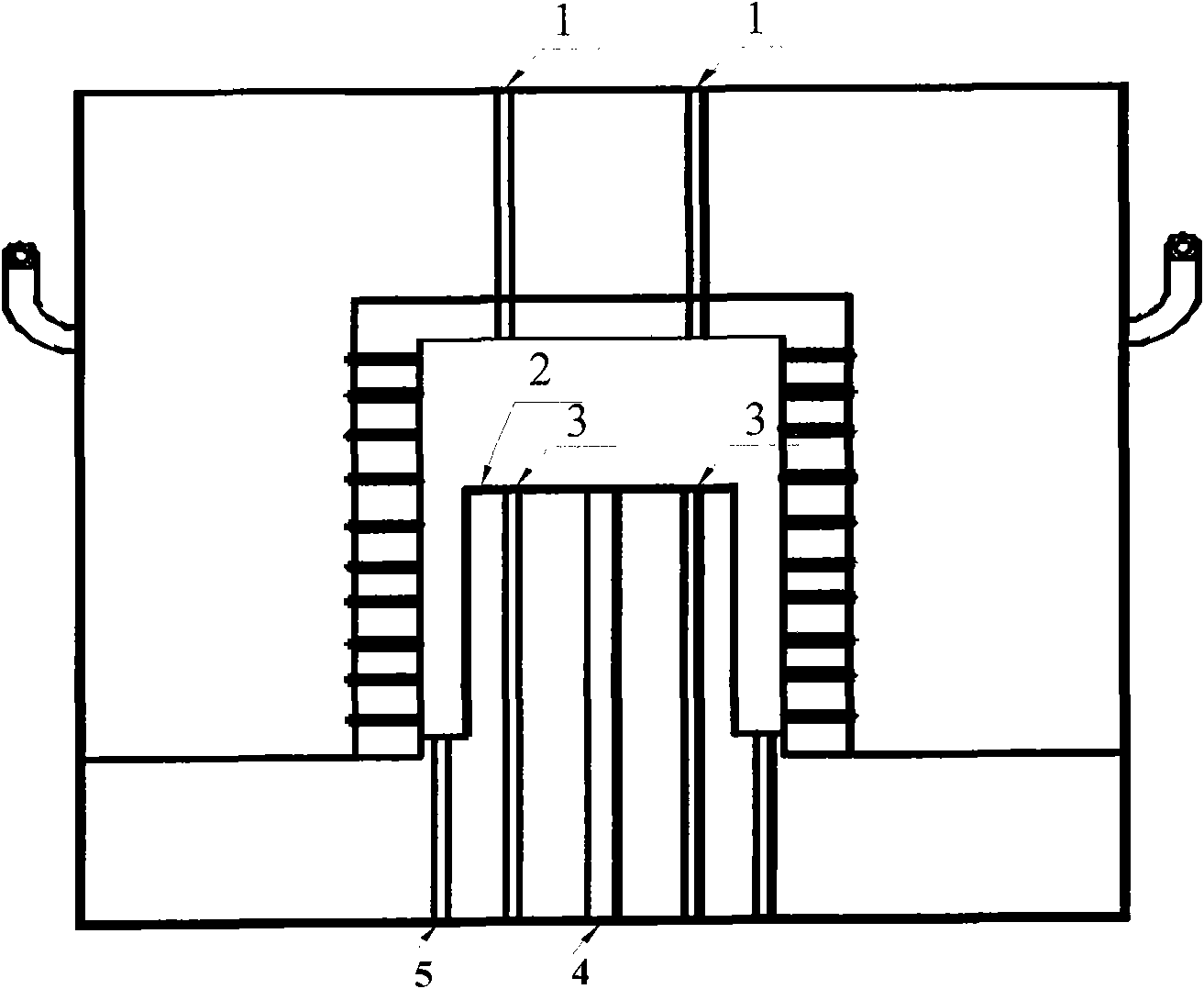

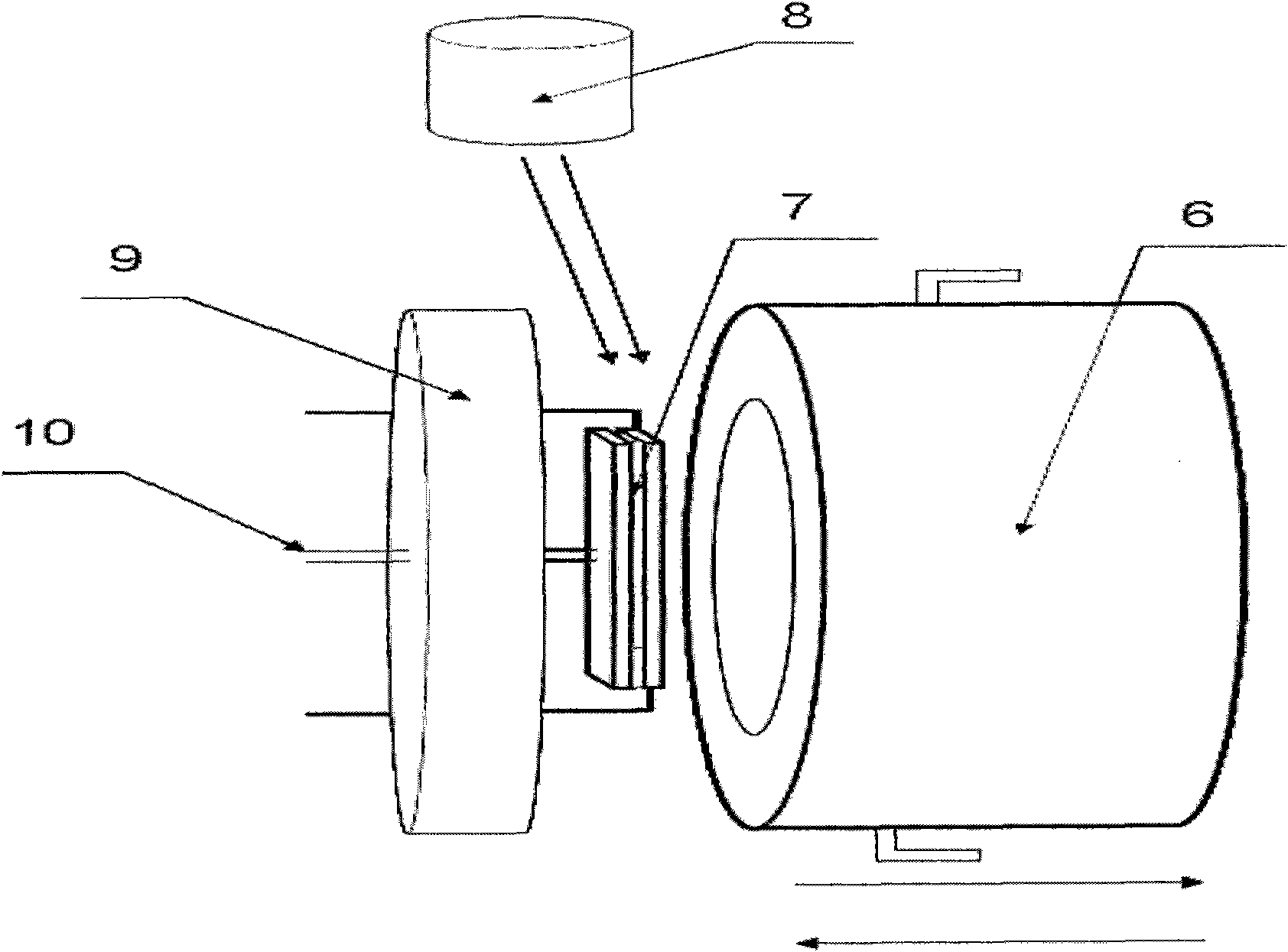

[0025] The dynamic voltage measuring system in the present invention includes a YD-28A type dynamic resistance strain gauge, an aluminum wire, and an IA-20 type high-precision constant current source. The data acquisition and processing system includes a computer and an A / D acquisition card. The main body of the heating / cooling system is a resistance furnace, equipped with a furnace body thermocouple 4 and a temperature controller, figure 2 A schematic diagram of the system structure is given. It can be seen that the sample is placed on the sample stage 2 of the resistance furnace, and the thermocouple wire 10 [the thermocouple wire is composed of two thermocouple wires with opposite magnetic properties, and is used to measure the temperature of the sample. temperature], and connected to a high-precision constant current source (with an accuracy of ±0.5, and a current range of 0-15A) through an aluminum wire 3, to ensure that the current of the sample to be tested is constant...

Embodiment 2

[0030] 01970 aluminum alloy, at the beginning of the test, quickly move the furnace to the distance where there is no temperature conduction to the sample, and completely air-cooled. Figure 5 Shown is the resistance (voltage)-temperature curve and the judged phase transition start and end points obtained at this cooling rate [the average cooling rate is 45.5°C / min] for 01970 aluminum alloy, and the average cooling rate is 45.5°C / min . In combination with Example 1, it can be seen that the present invention is applicable to different grades of aluminum alloys, and the obtained curves tend to be roughly the same, and the present invention has universality for measuring the phase transition points of different aluminum alloys.

Embodiment 3

[0032] 7A04 aluminum alloy, at the beginning of the test, quickly move the furnace to a distance where there is no temperature conduction to the sample, and at the same time cool the sample with the second gear of the air-conditioning fan with ice. Figure 6 Shown is the resistance (voltage)-temperature curve and the judged phase transition start and end points obtained at this cooling rate [the average cooling rate is 594.7°C / min] for 7A04 aluminum alloy, and the average cooling rate is 594.7°C / min . It can be seen that, compared with Example 1, the phase transition start point of the curve is lower, and there is no phase transition end point. For the same aluminum alloy, different phase transition points will be obtained at different cooling rates.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com